ETP for Milk manufacturing or Milk Processing unit

Milk manufacturing or milk processing units are an integral part of the dairy industry. These units process raw milk into various dairy products such as butter, cheese, yogurt, and other dairy products. During the milk processing, a large amount of wastewater is generated that needs to be treated before discharging into the environment. The most effective way to treat this wastewater is by installing an Effluent Treatment Plant (ETP).

Let us now discuss the process flow diagram and working process of designing an ETP for milk processing units in detail.

Stages of ETP for Milk Manufacturing Unit:

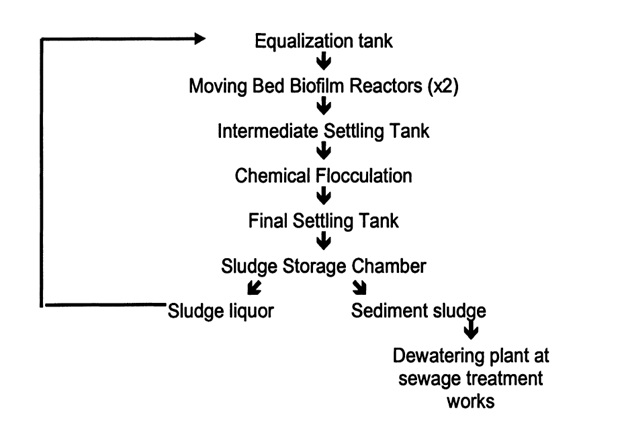

The process flow diagram of an ETP for a milk manufacturing unit includes various stages of treatment. The primary treatment includes a screening process, where large particles such as stones, plastics, and other foreign particles are removed. The wastewater is then subjected to physical treatment, where suspended solids are removed by sedimentation or flotation. After physical treatment, the wastewater is subjected to biological treatment, where organic matter is removed by microbial activity. The treated wastewater is then subjected to secondary treatment, where the remaining suspended solids are removed. Finally, the treated wastewater is disinfected to kill any harmful pathogens before discharging into the environment.

Working Process.

The working process of an ETP for milk manufacturing units is as follows:

a) Screening Process:

The first stage of the ETP is the screening process. The wastewater is passed through a screen that removes large particles such as stones, plastics, and other foreign particles.

b) Physical Treatment:

After screening, the wastewater is subjected to physical treatment, where suspended solids are removed. In this process, the wastewater is passed through a sedimentation tank or flotation tank. In the sedimentation tank, the suspended solids settle down due to gravity, whereas in the flotation tank, the suspended solids float to the surface due to the addition of chemicals. The settled or floated solids are removed by a scraper or skimmer.

c) Biological Treatment:

The wastewater is then subjected to biological treatment, where organic matter is removed by microbial activity. In this process, the wastewater is passed through an aeration tank, where air is provided to promote the growth of microorganisms. The microorganisms use organic matter as a food source and convert it into carbon dioxide and water.

d) Secondary Treatment:

After biological treatment, the wastewater is subjected to secondary treatment, where the remaining suspended solids are removed. In this process, the wastewater is passed through a clarifier, where the remaining suspended solids settle down due to gravity.

e) Disinfection:

Finally, the treated wastewater is disinfected to kill any harmful pathogens before discharging into the environment. In this process, the treated wastewater is subjected to chlorination or ultraviolet radiation.

Summary:

An Effluent Treatment Plant is an essential component of a milk manufacturing or processing unit. The ETP helps to treat the wastewater generated during the milk processing before discharging into the environment. The process flow diagram and working process of designing an ETP for a milk manufacturing unit include various stages of treatment such as screening, physical treatment, biological treatment, secondary treatment, and disinfection. By designing an ETP as per the process flow diagram and working process, the milk processing unit can ensure that the wastewater generated during the milk processing is treated effectively, and the environment is not polluted.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.