What are the Process flow diagram and Working of ETP?

Textile industry is one of the oldest and most important businesses in Indian economy. It accounts for around 2% of GDP, 8% of tax collections, 14% of industrial production, and 12% of overall manufacturing export profits.

India's textile sector consumes 1,608 MLD (million liters per day) each day. If the wastewater from these companies is not purified and released or repurposed, it pollutes the surrounding water, adding to the country's water problems.

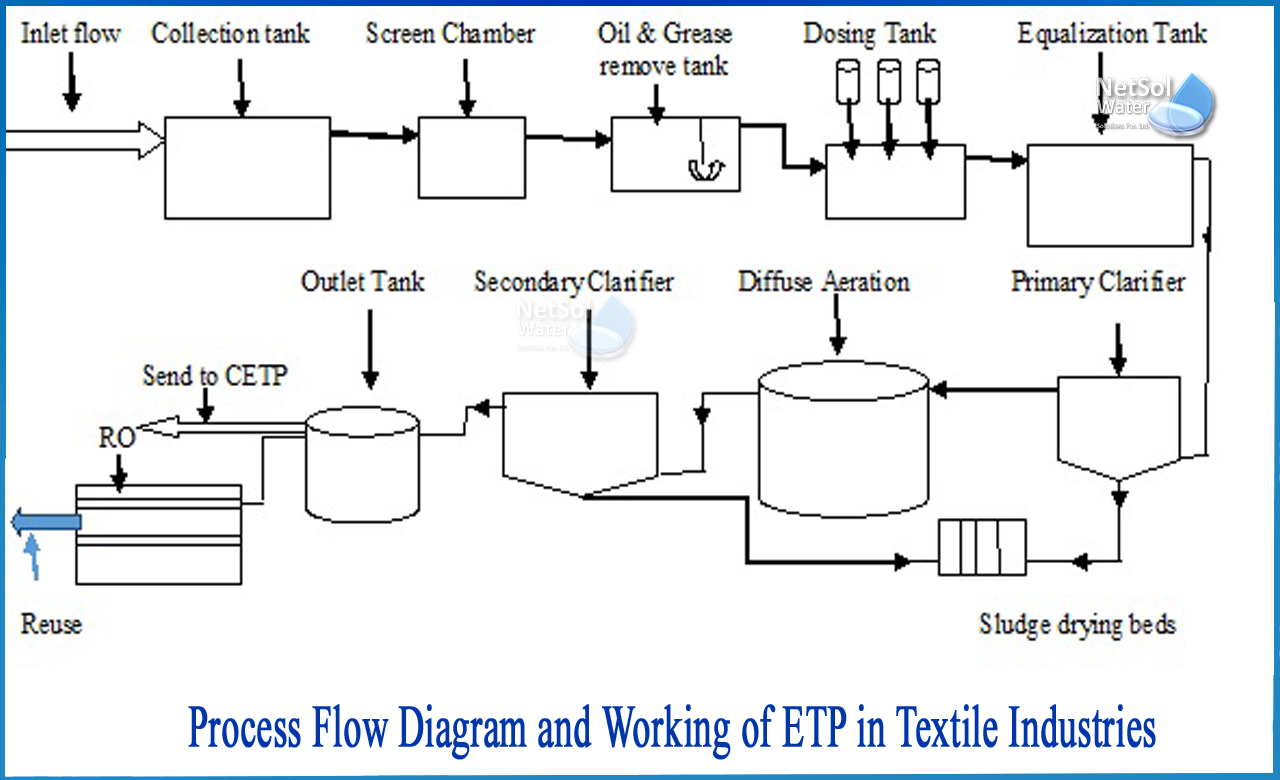

Effluent Treatment Plant in Textile industry - Process flow diagram

Effluent is the wastewater that flows out of a treatment plant, sewer, or industrial outfall, whether treated or untreated.

Wastes released into surface waters are generally referred to as wastewater. A plant that treats wastewater from industries and makes it environmentally pleasant is known as an effluent treatment plant.

In textile industry, ETP is used to remove the colour and chemicals that are present in the dyeing house's water. In the many phases of the dyeing process, dyehouse water contains a variety of substances. These treatments are used based on a variety of factors, including the wastewater's properties and the facilities' available space or location.

The following is a flow chart of the Effluent Treatment Plant (ETP) process:

Collection Tank

↓

Wastewater storage tank

↓

Primary filtration

↓

Mixing & Cooling

↓

Neutralization (by acid or alkali)

↓

Chemical Coagulation

↓

Biological Oxidation Tank

↓

Sedimentation & Separation of Sludge

↓

Sludge Thickener

↓

Filtration

↓

Discharge to Drain

Working of ETP in Textile industries

Untreated textile effluent contains significant quantities of TSS, dyes, chemicals & auxiliaries, metal toxicants, and BOD, and must be treated before being discharged into the Environment. Pollutants are removed from wastewater as it goes through the ETP, and the water quality is enhanced to an acceptable/standard level, allowing for safe ultimate discharge to the environment.

Physical, chemical, and biological mechanisms are frequently used combined in ETP.

In general, an effluent treatm?ent plant has four levels of treatment, which are briefly outlined below in order:

1: Preliminary Treatment

It is also known as pre-treatment, and it entails the use of a physical mechanism to treat wastewater. It entails screening, which involves using bar screens to remove large solids such as rags, fabric, yarn, sticks, and other debris that could harm the plant's equipment. The wastewater is next exposed to the physical treatment stage.

2: Primary Treatment

It entails physical and chemical techniques for wastewater treatment. When wastewater is pumped into the primary tank, it remains there for a long period, causing heavier particles to settle to the bottom and lighter particles to float to the top. Flocculation and coagulation are used to remove settled and floatable debris, and the water is then sent to a secondary or biological treatment.

3: Secondary Treatment

The wastewater that enters the secondary tank is particle-free and involves a biological mechanism. Most ETPs use biological treatment to remove BOD, which includes aerated lagoons, activated sludge, trickling filters, and oxidation ponds, but the activated sludge process is the most versatile biological oxidation method used for wastewater treatment. Approximately 80% of organic waste will be eliminated here, followed by tertiary treatment.

4: Tertiary Treatment

Physical, chemical, and biological mechanisms are used to remove remaining suspended solids, dissolved solids, and other contaminants that were not eliminated during the previous treatment steps. Several disinfection agents, such as chlorine, ozone, and UV radiation, are commonly utilized depending on the wastewater quality. After this treatment, the wastewater is ready to be disposed of or reused.

Need of an ETP

1: To clean industry wastewater and recycle it for further use.

2: To minimize the utilization of fresh/potable water in Industries.

3: To reduce the expenses spent on water procurement.

4: To avoid expensive penalties by meeting the Government's standards for emission or discharge of environmental contaminants from various industries.

5: To protect the environment from pollution and contribute to long-term development

Benefits of ETP

We live in a world where pollution is a serious concern for the entire population. It can be of any type, including air, water, and others. As our society and industry expand on a big scale, so does water pollution, which has increased by 100%. As a result, enterprises must treat garbage before discharging it into the environment.

ETP Plants play a critical role in this process, providing the following benefits: -

1: Reduces the expense of off-site treatment.

2: During the processing, no unnecessary water is used.

3: Makes your business self-sustaining.

4: Aids in the reduction of contaminants in natural water bodies and the preservation of the environment for future generations.

5: The most cost-effective and environmentally beneficial way is to use an effluent treatment plant.

What can we offer?

Netsol Water is one of the leading water and wastewater treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines, which not only turns your wastewater into usable water but also acts as a savior of Mother earth and its precious resource “water”.