What are the pros and cons of advanced oxidation process?

There are a number of pollutants in many water and wastewater treatment applications that are difficult to reduce through physical, chemical, or biological means alone.

Pharmaceutical drugs in drinking water and aquatic environments have become a growing source of concern in recent years. Pesticides are deposited in freshwater supplies by farm runoff. Personal care products are typically washed down the drain into the system to which they are connected. Leachate from landfills is a toxic cocktail of compounds that can leach into groundwater sources. Because they are so small, such contaminants are classified as micro-pollutants.Their size alone contributes to the difficulty of removing them from water and wastewater using certain methods.

Advanced oxidation

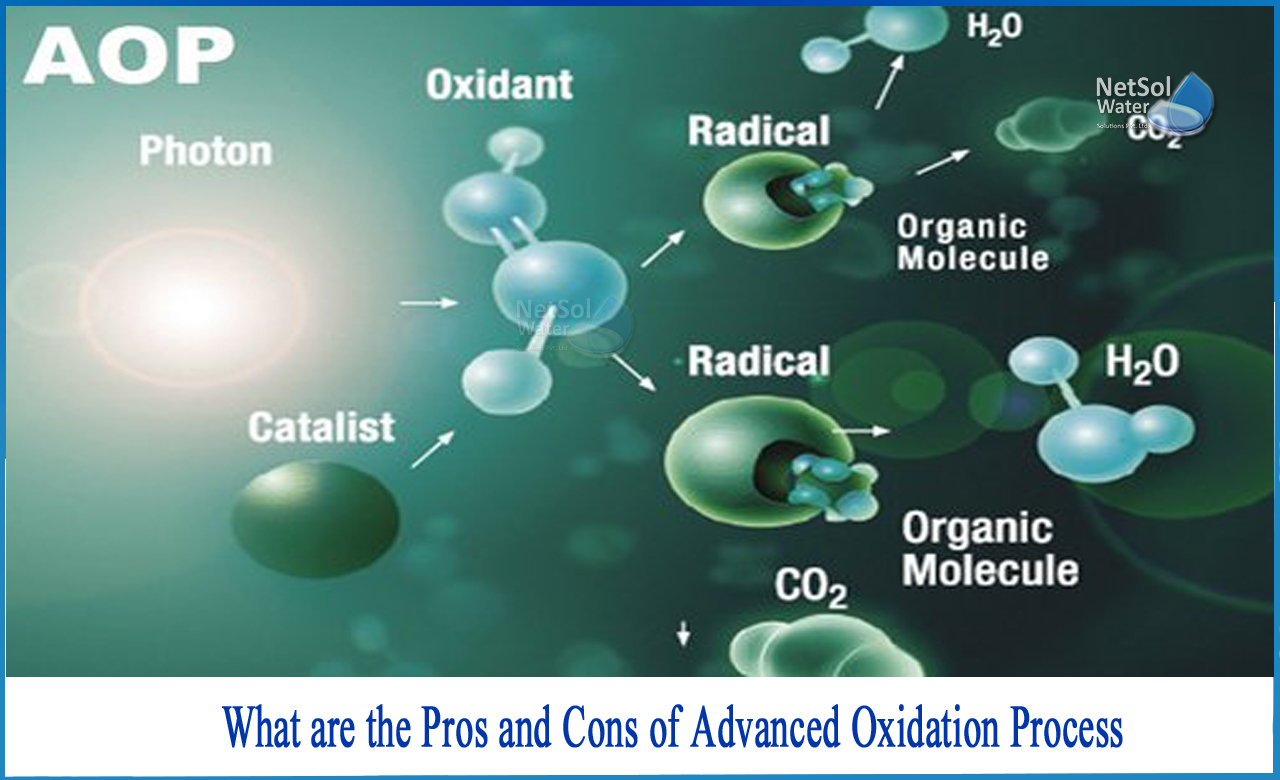

Advanced oxidation processes are a type of chemical treatment that is used to oxidize organic compounds found in wastewater that are difficult to handle biologically in order to convert them into simple finished products. These are widely recognized as effective water treatment techniques capable of oxidizing a wide range of hard degradation pollutants from water. Nonetheless, these are expensive processes due to their electrical costs, but this limitation can be resolved or reduced by using photovoltaic energy to power the AOP in a reliable and autonomous manner.

This process produces strong oxidizing agents in the form of hydroxide (OH–), but more specifically, its neutral variant, the hydroxyl radical (OH). It has twice the oxidation potential of chlorine, a commonly used disinfectant. Many advanced oxidation processes are propelled by hydroxyl radicals.

Here are just a few of the pros and cons of this particular procedure:

What are the pros?

1: Rapid response times

Because of its high oxidation potentials and non-selective nature, the OH molecule has some of the fastest reaction rates of all oxidants used to treat water and wastewater. Because of the rapid reactions, retention times are much shorter than in other conventional treatment processes.

2: Minimalist footprint

Because of the OH radical's oxidation power, advanced oxidation process units do not require much land area to process the system's required flow rate.

3: In theory, new hazardous substances should not be introduced into water

One of the problems with chlorine disinfection is the formation of highly toxic byproducts (DPBs) after treatment. To avoid these byproducts, an additional de-chlorination step is frequently required before anything else can be done with the treated water. Water can be formed by combining OH molecules. The most significant issues would be bromate formation and excess peroxide, but these can be addressed in a well-designed advanced oxidation process system.

4: Organic mineralization

The process has the ability to convert organic materials in water into stable inorganic compounds such as water, carbon dioxide, and salts.

5: It is capable of treating nearly all organic materials and removing some heavy metals

Because of the highly reactive nature of OH, these molecules will attack almost any organic material without discrimination, allowing them to remove a wide range of contaminants in a single reactor vessel, including a few heavy metals.

6: Can be used for disinfection

The oxidation power of these systems, especially when combined with UV disinfection, allows them to act as a disinfection step for any pathogens that may be present in the water.

7: There is no sludge production, as there is with chemical or biological processes

Advanced oxidation does not treat water and wastewater by transferring pollutants to another phase. Other treatment processes generate solids such as sludge, which must be filtered and dealt with separately.

8: It does not concentrate waste for further processing

Membranes, for example, result in higher concentrations of waste contaminants because they only separate clean water from pollutant compounds. Meanwhile, this process directly reacts with pollutants, converting them to harmless compounds. As a result, their concentrations in the effluent are reduced by this process.

What are the cons?

1: Capital and operating/maintenance costs are relatively high

The cost of this process is perhaps its most significant disadvantage. The most significant are the operating and maintenance costs incurred as a result of the system's need for energy and chemical reagents.

2: Chemistry that is complex and tailored to specific contaminant

There are several types of advanced oxidation processes. These variants must be carefully chosen in order to effectively treat the water/wastewater in question. Because this is a dosage-dependent process, the appropriate amounts of OH molecules are formed to achieve the desired level of treatment. Such complex chemistry will almost certainly necessitate the use of highly skilled engineers to properly design the system.

3: Removal of residual peroxide may be necessary

The systems which use hydrogen peroxide, should be carefully monitored for residual H2O2, as it can have a negative impact on subsequent treatment steps. Humans may be harmed by the residual hydrogen peroxide.

For further information, contact the water treatment experts at Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.