What is Packaged Sewage treatment plants based on MBR?

Membrane bioreactors (MBRs) are wastewater treatment methods that combine a selective membrane process such as reverse osmosis, microfiltration or ultrafiltration, with a biological process, especially a suspended growth bioreactor. These are distinct from 'polishing' methods in which the membrane is used as a separate tertiary treatment step with no return of active biomass to the biological process.

Almost all commercial MBR technologies in the market today employ the membrane as a filter, rejecting the solid debris produced by the biological process and producing a cleared and disinfected product effluent.

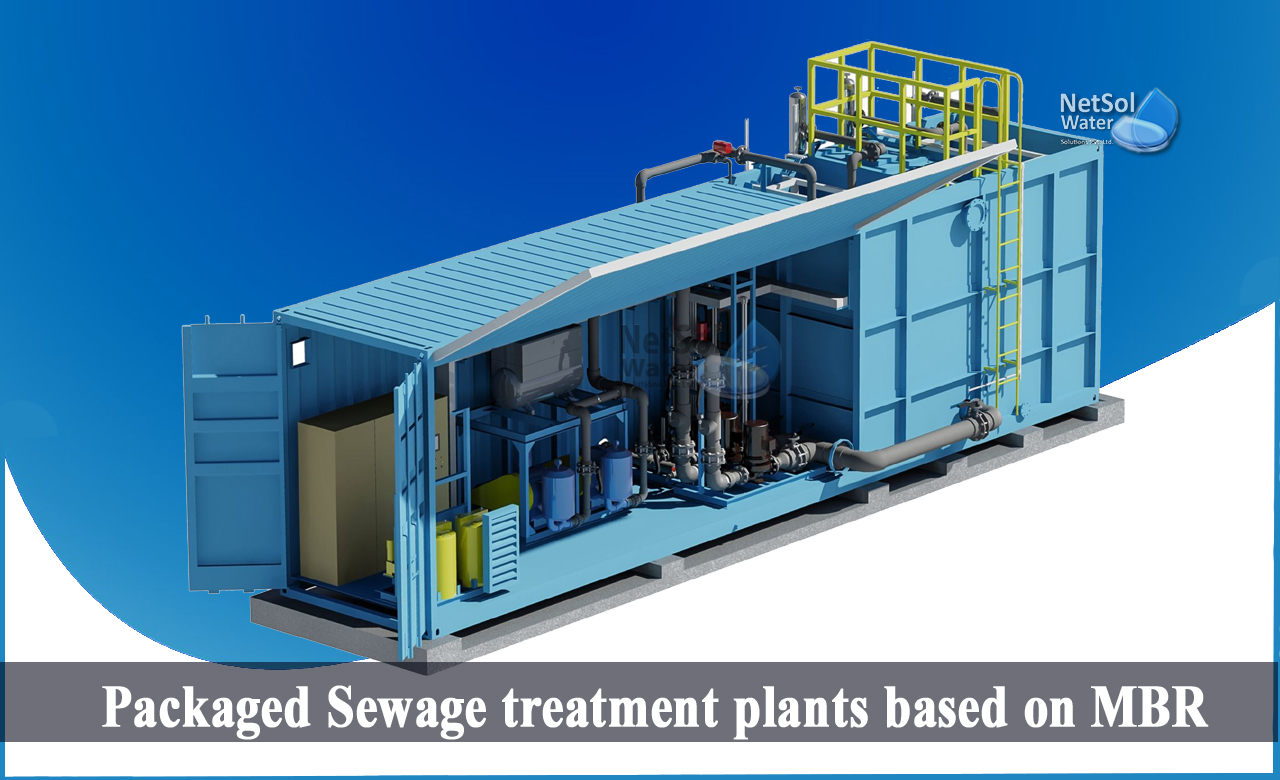

Packaged Sewage Treatment Plants (PSTPs) based on MBR

These are built particularly for smaller flows, such as home developments, mobile home communities, RV Parks, campgrounds, seasonal communities, and recreational facilities. These frequently have tight sewage discharge regulations, but with lower and variable volume requirements. There are frequently strong reasons for water reuse on the site.

Working Mechanism of PSTPSs based on MBR

· Semi-permeable membranes, which are two-dimensional materials, are immersed in aerated biological reactors in MBR technology systems.

· This level of filtration enables for higher sewage quality to be pulled through the membranes.

· It also assists in the removal of wastewater treatment procedures such as sedimentation and filtration.

· Since sedimentation is no longer required, the biological process may run more efficiently.

· Before the waste reaches the membrane tank, it is fine-screened or pre-treated. It helps to preserve the membrane and extend its life by reducing solid waste accumulation.

Technical details of our MBR technology

Our Packaged MBR technology is applicable to a wide range of wastewater treatment applications that demand high quality effluent, either to fulfil regulatory standards or for reuse.

Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), Bacteria, Total Coliforms, Ammonia, Nitrogen, and Phosphorus are all goals for our packaged MBR.Many medications are also removed from the waste stream, which is a rising problem for natural environments and drinking water. We can also provide solutions for developing contamination concerns such as PFAS and other chemicals that may be present in system effluent.

Removal rates of Packaged MBRs

|

Parameter |

Inlet |

Outlet |

Removal Rate (%) |

|

BOD |

350 |

5 |

98.6 |

|

COD |

700 |

50 |

92.9 |

|

TSS |

200 |

5 |

97.5 |

|

TN |

20 |

4 |

80 |

|

TP |

10 |

1 |

90 |

Features of packaged MBR Sewage Treatment Plant

· Our device has an online backwash mechanism to ensure continuous functioning with no interruptions.

· It is capable of producing high-quality treated water.

· It is intended to reduce associated expenditures and chemical use.

· It does not necessitate the use of separate settler, clarifier, and polishing equipment.

· It is adaptable in that it can work both below and above ground.

· It is environmentally friendly.

· Without a UF, it is possible to reach the greatest treatment standards.

• Minimal maintenance and trouble-free operation.

• Less or no odour.

• An optimized design can result in energy savings.

Applications of Packaged MBRs

· Housing Developments

· Campgrounds

· Golf Courses

· Retirement Homes

· Commercial Sectors

· Producing Industries

· Chemical Industries

· Oil & Gas Industries

· Pharma Industry

· Beverage Industry

· Textile Industry

What do we offer?

We take great pleasure in introducing ourselves as a prominent water and wastewater treatment firm in India, specialized in the production of WTPs, WWTPs, ETPs, as well as Energy Management, Automation Solutions, Asset Management, and Waste Management. We are a one-stop utility partner for both industrial and commercial clients, assisting them in enhancing resource productivity and bottom lines while protecting the environment.