1000 LPH Commercial RO Plant for Pharmacy Manufacturers: Design, Design Basis, Process Flow and Working Function

The pharmaceutical manufacturing industry requires high-quality water for various processes such as drug formulation, cleaning, and other applications. Reverse Osmosis (RO) technology is commonly used to produce pure water suitable for such purposes.

Here we will design a 1000 LPH commercial RO plant for the pharmaceutical manufacturing industry. The design basis, process flow diagram, and working function will be also discussed in detail.

Design Basis:

The design basis of a 1000 LPH RO plant for the pharmaceutical manufacturing industry is determined based on the water quality requirements for various processes. The design basis includes the following parameters:

· Feed Water Quality:

The feed water quality for the RO plant should be analyzed to determine the appropriate pre-treatment steps. In the pharmaceutical industry, the feed water quality requirement is generally high, and the water must be free from impurities, such as dissolved solids, organic matter, and microorganisms.

· Permeate Water Quality:

The permeate water quality requirement depends on the application. In the pharmaceutical industry, the permeate water quality is generally higher than that required for drinking water. The permeate water quality should be analyzed to determine the appropriate post-treatment steps.

· Recovery:

The recovery of the RO plant determines the amount of water that is produced from the feed water. A higher recovery rate increases the water production and reduces wastewater generation.

· Energy Consumption:

The energy consumption of the RO plant should be minimized to reduce operating costs.

Process Flow Diagram:

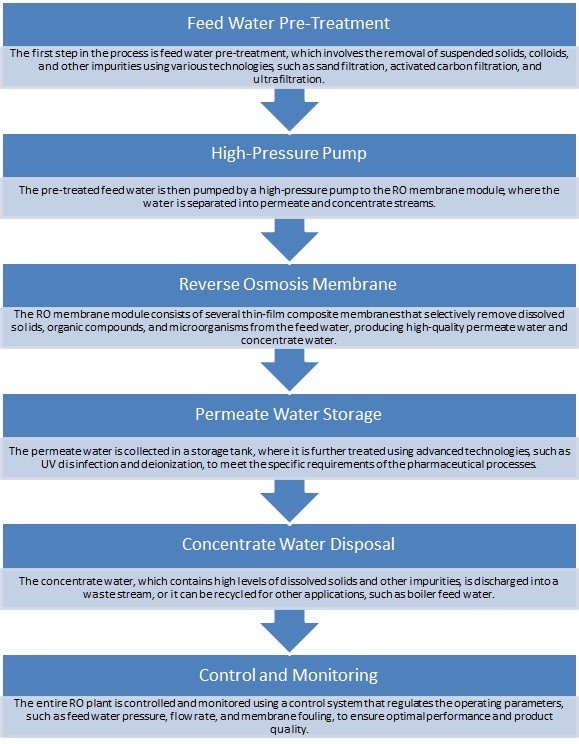

The process flow diagram of a 1000 LPH RO plant for the pharmaceutical industry is shown in the figure below.

Working Function:

The working function of RO plant for the pharmaceutical industry can be explained as follows:

· Pre-Treatment:

The pre-treatment step involves the removal of suspended solids, organic matter, chlorine, and hardness from the feed water. The multi-media filter removes suspended solids and turbidity, while the activated carbon filter removes organic matter and chlorine. The water softener removes hardness from the water.

· RO Membrane:

The pre-treated water then enters the RO membrane module, where the high-pressure pump applies pressure to the feed water to push it through the RO membrane. The RO membrane removes dissolved solids, such as salts and minerals, and produces purified water, called permeate. The rejected water, called concentrate, is discharged as wastewater.

· Post-Treatment:

The permeate then enters the post-treatment section, where it is passed through a deionization unit to remove remaining dissolved ions. Then, it is passed through an ultrafiltration unit to remove any remaining particles and bacteria. Finally, the water is disinfected using a UV sterilizer and stored in a clean water storage tank.

· Control and Monitoring:

The RO plant is equipped with various sensors, such as pressure sensors and flow meters, to monitor the operating parameters. The control system adjusts the operating parameters, such as the pressure and flow rate, to maintain the desired water quality and production rate.

Summary:

Thus the design of a commercial RO plant for the pharmaceutical industry requires careful consideration of various parameters, such as feed water quality, permeate water quality, recovery rate, and energy consumption. The process flow diagram and working function of the RO plant were discussed in detail. The design of an RO plant involves several calculations and formulas, which are used to determine the operating parameters and optimize the system performance. The use of advanced pre-treatment and post-treatment technologies ensures the production of high-quality water suitable for various pharmaceutical processes.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information