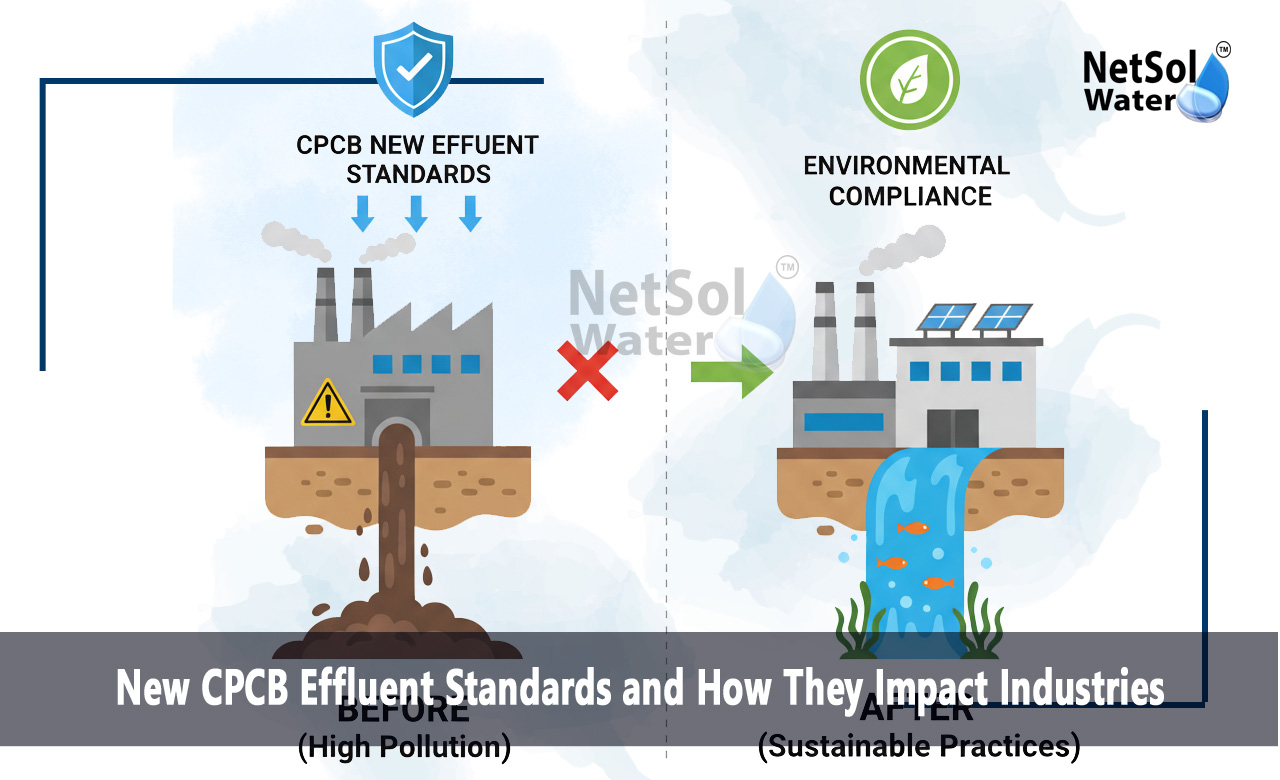

New CPCB Effluent Standards and How They Impact Industries

The fast industrialization in India has come with numerous economic advantages that cannot be ignored, yet, it has put additional pressure on our water resources. Unless industrial discharges are treated adequately, they may cause a serious pollution of rivers, lakes, and groundwater. In response to this, Central Pollution Control Board (CPCB) periodically revises the discharge standards of industries to balance the environmental objectives and international best practices. The New CPCB effluent standards are considered as one of the greatest regulatory measures in the recent years, that are put with the aim of reducing loads of pollution, increasing the efficiency of wastewater treatment process, and encouraging sustainable industrial operations.

Reasons why the New Standards were introduced

India had decades of industries that were running with old effluent limits which were no longer relevant to the new environmental challenges and technological capability. The increase of the industrialization and lack of water and environmental deterioration caused the need of renewing these standards.

The new guidelines by the CPCB have introduced a new lower limit of parameters like Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solids (TSS), heavy metals and oil and grease. They also incorporate additional parameters with regards to new pollutants and nutrient loads especially on such sectors as textiles, tanners, pharmaceuticals, and food processing.

The main objective is not merely to suppress pollution, but also to make industries use cleaner technologies, recycle treat water, and, where possible, to transition to zero liquid discharge (ZLD) systems.

Read: Effluent Treatment Plant Manufacturer

Major Characteristics of the New CPCB Effluent Standards

The New CPCB effluent standards concentrate on two key aspects, which include a reduction of the concentration of the harmful substances released in the discharged water and also encouragement of efficient reuse and recycling in the industrial process.

Among the key highlights, there are:

1: Higher limits of BOD and COD to guarantee increased organic matter breakdown.

2: Addition of nutrient parameters such as nitrogen and phosphorus to regulate eutrophication in the receiving waters.

3: Stricter regulations on harmful metals like chromium, lead, mercury and arsenic.

4: Implementation of effluent reduction and water recovery regulation of water consuming industries.

5: Compulsory online monitoring of effluent to facilitate constant compliance.

6: Targets of reuse and recycling that will be integrated to facilitate circular management of water.

These modifications are an indicator of shift towards traditional compliance type systems to active environmental management.

Impacts on Industries

There will be far-reaching implications of the new standards within sectors. As they introduce some challenges, they are also exposing new opportunities of innovative thinking and sustainability in the long term.

1: Increased Need for Upgradation of Treatment Plants

Most of the current ETPs and STPs in industrial estates will require to be modernized. The traditional systems might fail to comply with the more rigorous discharge standards whereby industries are compelled to consider applying modern treatment technology such as membrane filtration, reverse osmosis and tertiary polishing units.

2: Increased Operational and Maintenance Costs.

Tighter limits imply more energy and chemical consumption in treatment, which leads to a slight increase in costs of operation. Nevertheless, industries can ensure that these costs are reduced with time with the help of an efficient system design, automation, and frequent monitoring.

3: Promotion of Water Recycling and Reuse.

It will now make industries more willing to use treated water in non-portable use like in cooling, landscaping and cleaning. This not only conserves fresh water requirements, but also assists in achieving compliance requirement, but also saves money in the long term.

4: Increase in the Environmental technology industry

The new rules give a chance to companies dealing with wastewater treatment technologies, equipment manufacturing, and consultancy services. It promotes innovation towards cost effective energy saving and compact treatment systems that can be used in industries.

5: Change the Direction to Sustainable Operations.

By complying with the new norms, the industries will re-examine their production processes, reduce the amount of waste produced, and adopt cleaner ways of production. Such a change adds to deeper objectives on sustainability, such as the meeting of Sustainable Development Goals (SDGs).

6: More Accountability and Transparency.

Regulatory bodies now have the ability to monitor real time effluent quality figures with the introduction of a mandatory online effluent monitoring systems to ensure that these systems are installed. This promotes transparency, lowers the rates of manual reporting errors and provides consistency in performances of industries.

7: Green Branding and Global Competitiveness Potential

Those industries that adopt the new standards can have a competitive edge and more particularly in the export-oriented industries where the environmental compliance is a major condition. Compliance with current effluent standards is a way of building brand image and investor trust.

8: Legal and Regulatory Implications.

Failure to meet the changed standards may attract severe fines, closure of business, or environmental licence. Therefore, the industrial sectors should focus on the environment auditing and constant observation to maintain their compliance.

Challenges Ahead

The adoption of the New CPCB effluent standards is not a smooth sail. SMEs, which are in most cases less technical and financially equipped, might not be able to meet the new requirements. To counter this, the popular effluent treatment plants (CETPs) within the industrial clusters should also be improved.

The government assistance in the form of subsidy, training and availability of cleaner technology funds will play an important role in ensuring that these industries switch to a smooth transition. Breaks in knowledge and resource bases can also be overcome through public-private partnerships and knowledge platforms.

The Road to Sustainable Industry.

All these new standards are not only a simple regulatory update, but they are a reflection of the changing environmental vision in India. With industries getting accustomed to these norms, they will help in having cleaner rivers, healthy ecosystems, and a more responsible industrial sector. With time, compliance will not be considered as a burden, but it will become a way to operational efficiency, innovation, and sustainability.

Conclusion

In India, the New CPCB effluent standards are a significant step in terms of environmental governance in India. Although they require dramatic changes to industries, they carry along with them efficiency, innovation, and environmental stewardship opportunities. Industries can make these challenges the engines of progress- making the environment cleaner and industrial future stronger and more sustainable, by investing in improved technology, encouraging water reuse, and continuing to get better with every improvement.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com