How to modify Anaerobic Process for EGSB Reactor?

Anaerobic waste treatment systems are becoming more widely acknowledged as a technique of recovering non-conventional energy. Anaerobic decomposition is a biologically mediated, natural process that may be mimicked to treat pollutants generated by municipal, agricultural, and industrial operations. Anaerobic digestion, as used in the treatment of sewage sludge and other organic wastes, is an example of a process that has been well managed.

Although anaerobic digesters have been used for decades to stabilize sewage sludge, their efficient and cost-effective usage for the treatment of liquid wastes is a relatively new phenomena, owing to the development of innovative reactor designs. These ideas have resulted in the creation of a number of reactors that can hold a significantly greater biomass concentration than standard digesters. This is made feasible by making sludge retention independent of influent retention time.

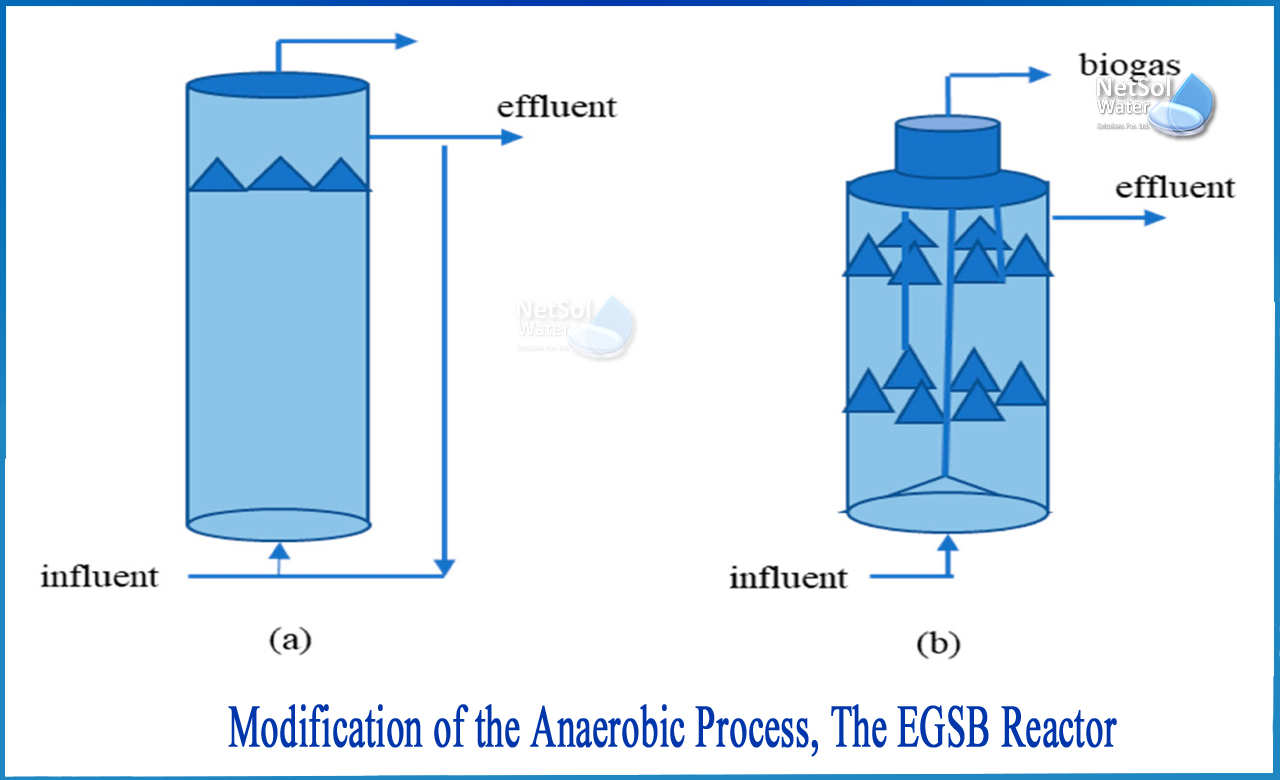

Modification of the Anaerobic Process

The removal of organic matter from sewage may be achieved efficiently using a typical UASB reactor at a mesophilic temperature, which is above 20 degrees Celsius. Some reactor modifications are required to make the anaerobic process suitable for wastewater treatment at lower temperatures and with low strength effluent. With certain modifications to traditional therapy, it is feasible to deliver treatment at a lower temperature and at a lower strength.

Below is mentioned modification such as the Expanded Granular Sludge Bed (EGSB) reactor:

The EGSB Reactor

Inside the UASB reactor, the sludge might be either flocculent or granular. The granular sludge (size 1 – 5 mm) has specific benefits over the flocculent sludge. Due to its high density, granular sludge has the highest microbe to space ratio, as well as a high settling velocity, strong methanogenic activity, and superior mechanical strength. The granular sludge form is formed mostly from soluble wastewaters. The granules' formation is mostly determined by the reactor's working parameters as well as the properties of the wastewater to be treated.

Granulation has yet to be reported in any of the full-scale UASB reactors that treat sewage.When proper mixing conditions are maintained in the laboratory size and pilot scale UASB reactors, biomass granulation is seen. Despite the use of a flocculent sludge structure for treating raw sewage, good BOD and TSS removal efficiency may be attained in all circumstances.

To keep the sludge bed biomass in expanded form in the EGSB reactor, a very high upflow velocity is maintained. The EGSB reactor is shown to be effective at removing soluble organic debris even at low temperatures. This is due to the high upflow velocity (6-12 m/h) resulting in extensive interaction between the entering organic matter and sludge granules, as opposed to less than 1 m/h in a normal UASB reactor. When the generation rate of biogas and therefore the mixing intensity generated by it are relatively low, EGSB reactors are helpful for wastewater treatment, particularly at low temperature and relatively low strength wastewater.

Conclusion

When compared to traditional UASB reactors, the higher kinetic energy content of the influent and the prolonged height of the enlarged granular bed contribute to superior performance. Due to the high up flow liquid velocity utilized in the EGSB reactors, it is insufficient for the removal of particle organic debris.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.