What microbes are used in anaerobic digestion and sludge dewatering?

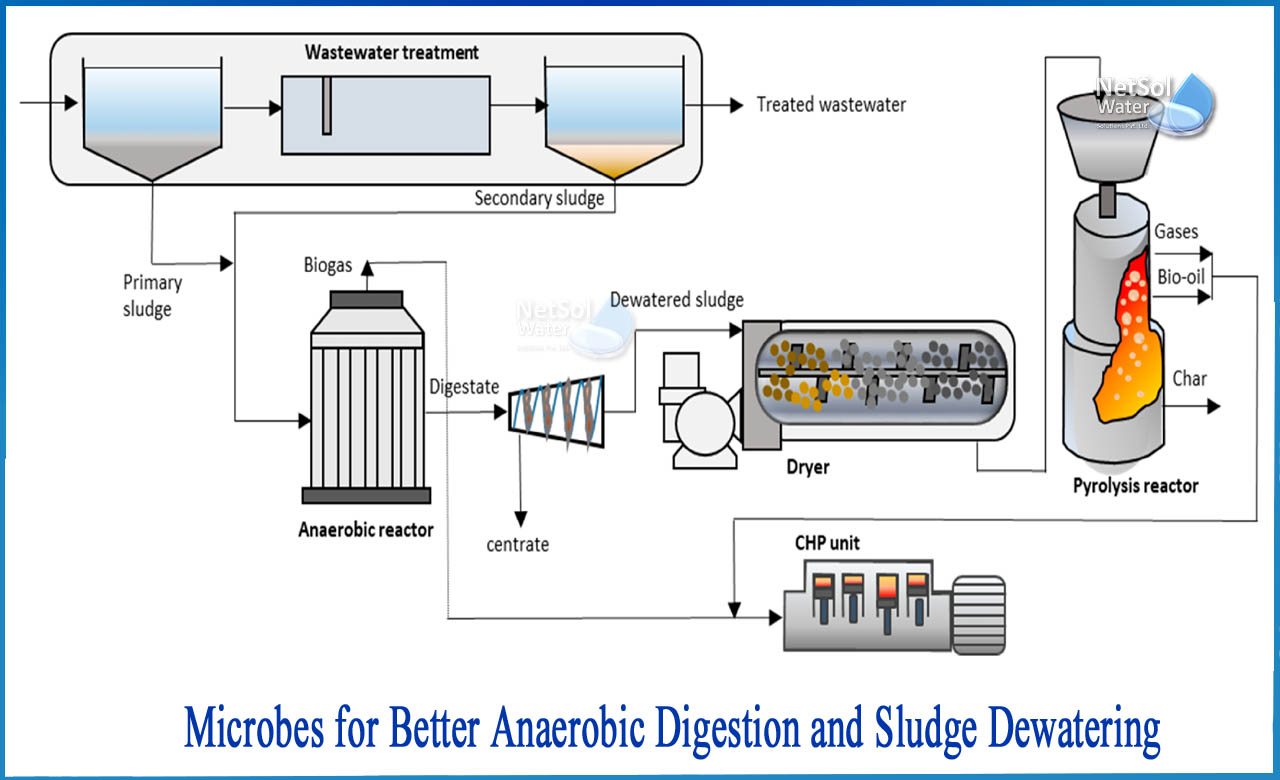

Anaerobic digestion is a process in which bacteria breaks down the organic matter in the absence of oxygen, such as animal manure, wastewater biosolids, and food wastes. Anaerobic digestion for biogas production occurs in a sealed vessel known as a reactor, which is designed and built in a variety of shapes and sizes based on the site and feedstock conditions. These reactors contain complex microbial communities that break down (or digest) waste to produce biogas and digestate (the solid and liquid material end-products of the AD process), which are discharged from the digester.

In general, the syntrophic process is carried out in the anaerobic degradation of organic compounds with the help of hydrolytic, acid-producing, acetate-producing, and methane-producing bacteria.The metabolic products produced by a group of bacteria are used as substrates for other microbes in this process.

Microbial Hydrolysis

The mutualistic behaviour of many anaerobic microbes, complex organic molecules are decomposed into simple, chemically stable chemicals, mostly methane and carbon dioxide.

The cooperation of four different kinds of microorganisms, namely fermentative, syntrophic, acetogenic, and methanogenic bacteria, allows for the conversion of complex organic compounds. Microbes use a variety of strategies to get over the anaerobic digester's harsh conditions, such as competing for the same substrate between sulphate reducing bacteria (SRB) and methane-producing bacteria. Water at a wastewater treatment facility is teeming with all of these bacteria, both anaerobic and aerobic.

The bacteria produces hydrogen sulphide (H2S), which causes the water to smell if it is not treated. The sludge produced by these bacteria clogs the equipment, causing FOG (fats, oils, and grease) to accumulate in a wastewater treatment plant.

The hydrolysis stage can be thought of as a biological substrate preparation!

Extracellular enzymes released by the microbial population break down the polymeric components (lipids, proteins, and carbohydrates) in the substrate into low molecular-weight intermediates having molecular weights less than 1000 Da. After then, the cells take up the intermediates. The hydrolytic stage in anaerobic digestion relies heavily on enzyme expression and enzymatic activity. Some hydrolysis intermediates, such as ammonia and LCFA, have been reported to limit AD, necessitating microbial acclimation or operational techniques for successful digestion. Furthermore, hydrolytic organisms digest the monomers produced by hydrolytic enzymes while also producing acidogenesis intermediates such as SCCA and hydrogen. Parameters like substrate, inoculum, and environmental growth circumstances have a significant impact on the microbial community.

The following are some of the benefits of utilising bacteria:

· If correctly constructed and operated, odours will be reduced.

· In the return stream, there is a low level of ammonia and BOD.

Role of Netsol Water!

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. It is our mission to save the planet. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish.

Netsol Water is committed to providing our valued customers with hands-on service, expert counselling, and training. Every environmental problem and its management have a solution that we try to provide.

“Save Earth and its Resources Now” is our basic motto that everyone needs to follow.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.