What is the difference between Membrane and Biological Reactor?

The physical, chemical and biological methods used to eliminate pollutants from wastewater before dumping it into a waterbody are referred to as wastewater treatment. The facilities are designed to ensure that effluent does not harm receiving waterbodies and that they comply with Pollution Discharge permit criteria. Organic matter, nitrogen, and phosphorus are the three main components that need to be treated in domestic wastewater. Depending on the needs and resources of the community, treatment processes can take many different shapes. Pretreatment is frequently followed by primary and secondary treatment, as well as further advanced processes if resources are being recovered, at a Water Resource Recovery Facility (WRRF).

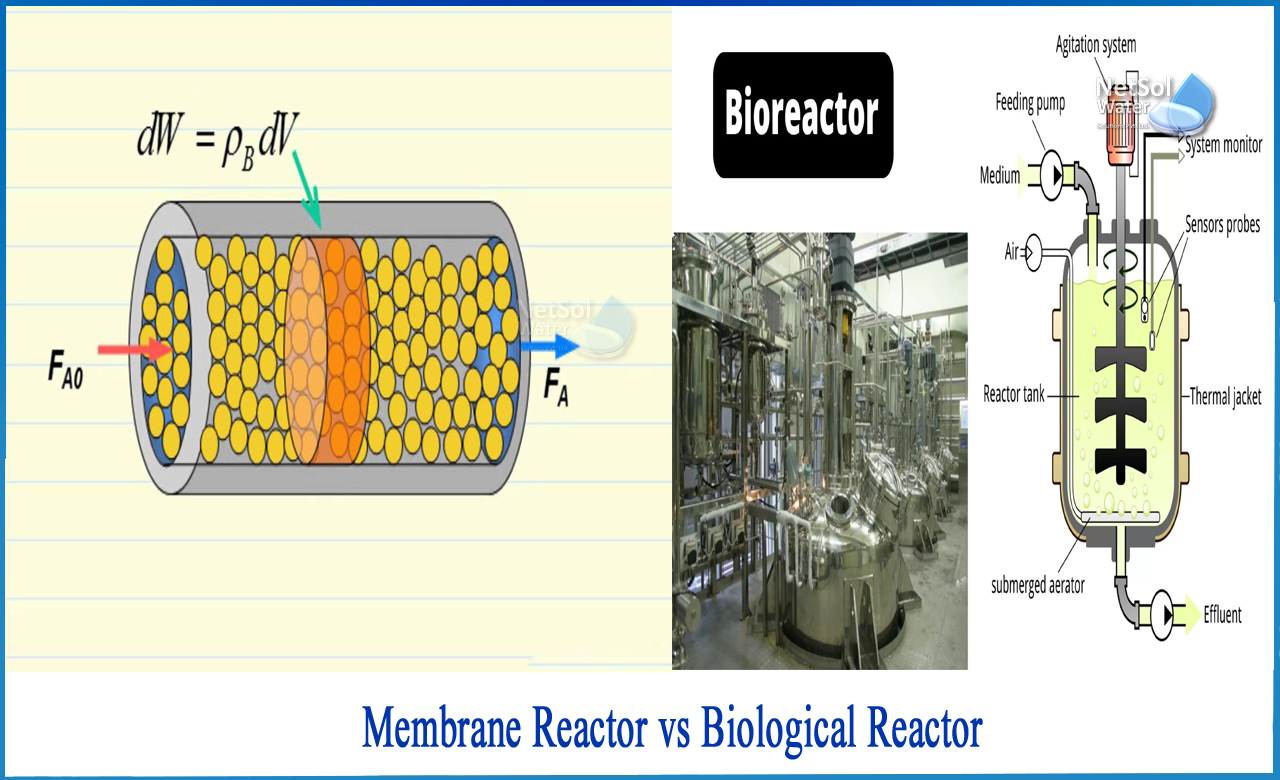

What are Membrane Reactors?

Membrane reactors combine a chemical conversion process with a membrane separation procedure to add reactants or remove reaction products.

Membrane reactors are chemical reactors that use membranes as a component. The membrane can be used for a variety of purposes:

1: Separation

2: Product extraction that is selective

3: The catalyst's retention

4: Reactant distribution/dosing

5: Catalyst assistance (often combined with distribution of reactants)

Membrane reactors, for example, combine two unit processes in a single phase, such as membrane filtration and a chemical reaction. When the reaction section is combined with selective extraction of a reactant, the conversions can be improved over the equilibrium value. Membrane reactors are well suited to performing equilibrium-limited endothermic reactions because of this property.

Membrane bioreactors are widespread in wastewater treatment, mixing a membrane such as reverse osmosis with a biological wastewater treatment method such as activated sludge. The membrane successfully eliminates sediments and microbes, while the activated sludge process cleanses the wastewater, resulting in clean water and solids that can be treated further before being discharged. When designing a membrane bioreactor, various factors must be taken into account, including fouling, correct mixing, and biological performance.

Inside the reactor, selective membranes have various advantages: the reactor portion can replace several downstream processes. Furthermore, eliminating a product allows for the circumvention of thermodynamic constraints. In this method, larger reactant conversions can be achieved, or the same conversion can be achieved at a lower temperature.

What are Biological Reactors?

Any manufactured equipment or system that ensures a biologically active environment is referred to as a bioreactor. A bioreactor is a vessel in which a chemical process involving organisms or biochemically active compounds produced from such organisms is carried out. This process might be aerobic or anaerobic in nature. These bioreactors are typically cylindrical in shape, with sizes ranging from litres to cubic metres, and are frequently composed of stainless steel. In the context of cell culture, it can also refer to a device or method for growing cells or tissues. These devices are being created for tissue engineering and biochemical/bioprocess engineering applications.

Microorganisms in biological reactors are used to treat wastewater in biological wastewater treatment.These microbes are eliminating organic debris and nutrients from the wastewater as they consume them for their growth. The microorganisms (now referred to as biomass) can be removed as solids, leaving a liquid part that can be treated to produce clean water. Depending on the architecture of the water resource recovery plant, biological reactors can be aerobic or anaerobic.

Large-scale immobilised cell bioreactors are:

- Moving media biofilm reactors, also known as moving bed biofilm reactors (MBBR),

- a stuffed bed

- a fibrous substrate

- membrane

How can Netsol Water help?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. We've made it our mission to save the planet. The company creates equipment and is committed to providing practical solutions that help businesses flourish.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.