As a necessary component of all urban and industrial sewage treatment plants, wastewater sieves retain the solids contained in wastewater. These solids can reduce the efficiency of the entire system, damage expensive and critical water treatment equipment, pollute water, and cause small to large-scale natural hazards throughout the ecosystem. Due to its nature, it should be removed at the beginning of the water or wastewater treatment process.

What are the various types of screens in Wastewater Treatment Plants?

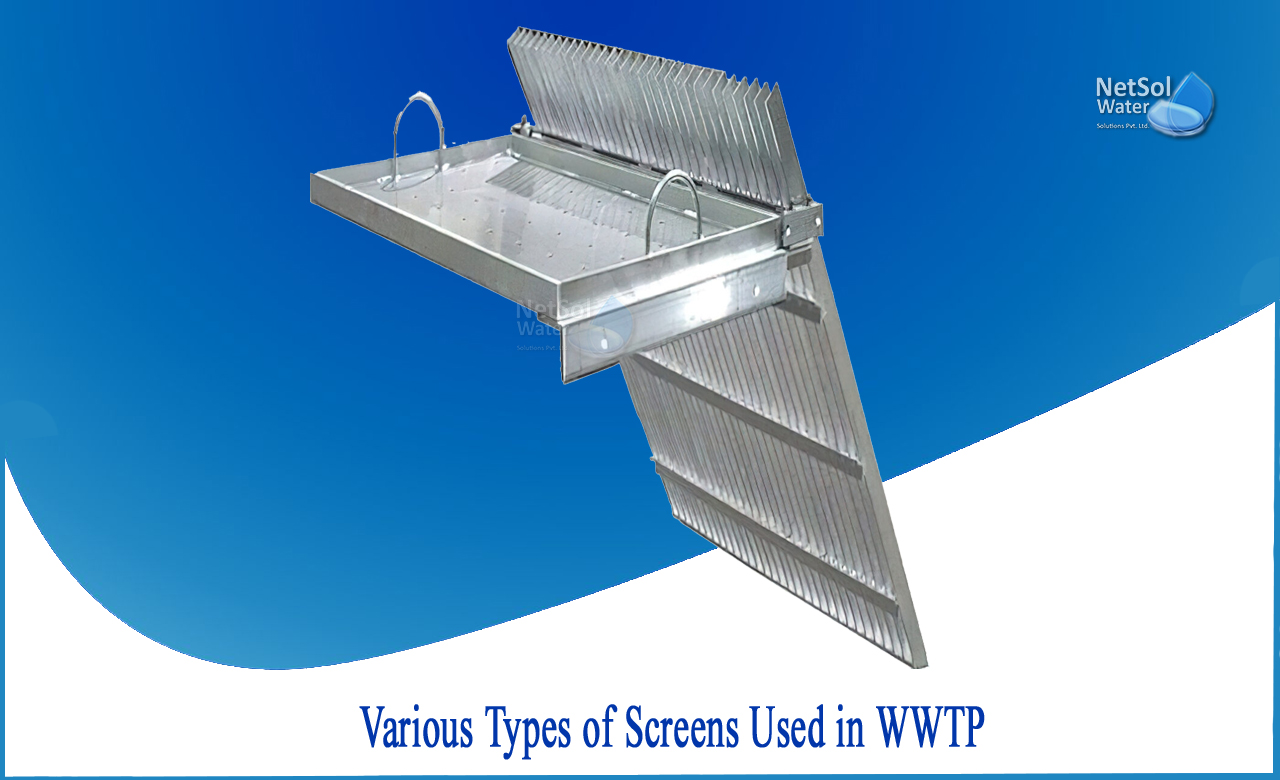

There are three major categories of wastewater treatment screens that can be categorized into coarse, fine and micro. There are different screening variations in these categories. Screens are categorized based on the size of the screen opening and other mechanical properties.

Rough screens in wastewater treatment

The smelting screen has a free opening in the range of 6 to 150 mm (0.25 to 6 inches). The screen consists of parallel bars, rods or wires, wire mesh, or perforated plates, usually with circular or rectangular openings. Also known as a "barracks," it is used to remove coarse solids such as rags and large items that can clog or damage other attachments.

Based on the sewage screening process used to clean them, coarse screens fall into two types:

-Hand screens

The rough, hand-cleaned screens used in the screening process for wastewater treatment in small plants are scraped by hand. They are ideal as a backup during periods of high flow or when repairing or servicing more modern mechanical screening methods.

-Mechanically cleaned screen

Rough mechanically cleaned screens increase efficiency and reduce problems in the wastewater treatment process.

Mechanically cleaned screens fall into five main categories:

1: Chain Driven Screens: These front and rear chain driven screens can be scooped upstream or downstream. Automatic chains clean up the stream and improve the functionality of the entire wastewater treatment solution.

2: Trolley Line Screens: These front-return, front-clean screens use an impressive yet uncomplicated internal mechanism to prevent further clogging in the presence of large or heavy objects.

3: Front and Back Rake: These wastewater treatment screening solutions, also known as climbing screens, use one rake instead of multiple, which can be inefficient under heavy load during the water treatment screening process.

4: Continuous Belt Screen: Ultra-high-tech, functional and efficient, this type of screen has many rakes and is capable of continuous and self-cleaning on both fine and coarse solid loads.

5: Micro-screen for wastewater screening:The smallest type of sieve in wastewater treatment is a micro-sieve. These screens are usually slow drum screens. The drum is lined with a filter fabric with an opening of 10-35 µm. Wastewater enters the drums and the remaining solid waste is collected and disposed of.

Fine screening at a sewage treatment plant

The screening process for wastewater treatment plants uses a screen called a fine screen with a transparent opening of less than 6 mm. They consist of wire mesh, wedge wires, or perforated sheets. Like micro-sieving, they are sieving tools used in wastewater treatment to remove fine solids.

The three common types of fine screening in wastewater treatment are:

1: Drum screen (rotating cylinder in the flow path);

2: Stage screen (fixing and moving the plate across the width of the channel);

3: Static wedge wire screen (used in large-scale wastewater treatment plants with large floor areas).

Page you May like: Commercial RO Plant Manufacturer in Delhi

How can Netsol Water help?

There are various types of screens each of which is used at particular level in treatment units and plants.

We at Netsol have more than 10 years of experience in manufacturing and installing sieves, waste water treatment plant manufacturing and operations. For water, wastewater or sludge treatment, we offer a complete spectrum of wastewater treatment products. Our engineers would gladly collaborate with your team to create the right design that meets your budget and objectives.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.