What is the working process MBR Technology?

MBR stands for Membrane Bioreactor, and it is a process that combines membrane, Reverse Osmosis, ultra/micro filtration and activated sludge.

Membrane Bio-Reactors (MBRs) have been more popular in municipal wastewater treatment during the last decade. Membrane filtration plays an important role in water and wastewater treatment, as it outperforms traditional water technologies in terms of performance and cost efficiency. In the conventional activated sludge process, the MBR process takes the place of the secondary sedimentation tank and sand filter for tertiary treatment. The MBR method works with a much broader set of parameters than the traditional activated sludge process.

MBR technology's scalability and mobility have opened new possibilities for satellite and remote treatment units.

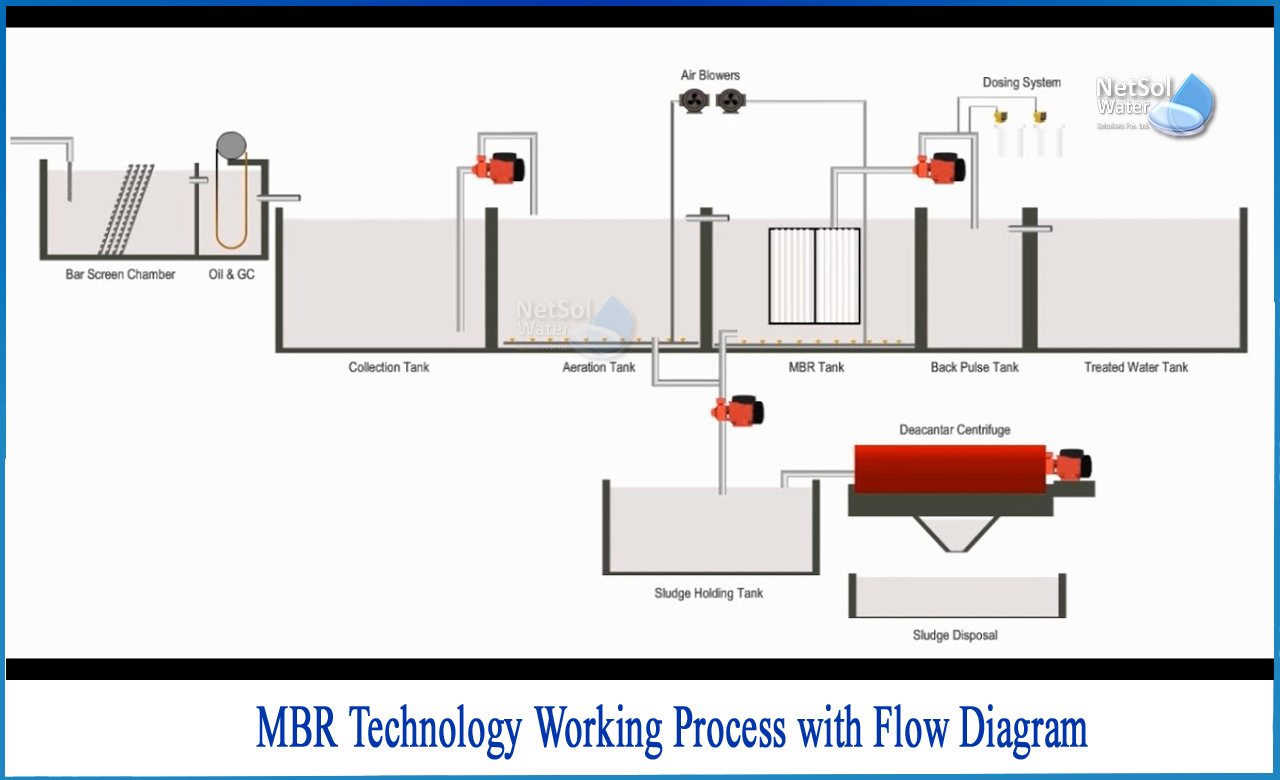

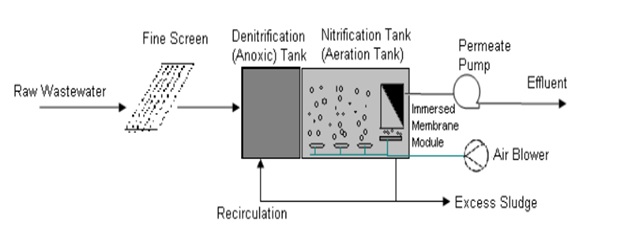

The diagram below is a typical MBR Process Flow Diagram:

Raw wastewater is often filtered using coarse and fine screens to eliminate particles that could harm downstream equipment and processes. The membrane module can be placed in either the aeration tank or a separate membrane tank. If denitrification is required for nitrogen nutrient removal, recirculation is used.

Working of MBR

1: The sewage waste and industrial effluent first enters the stilling chamber before being sent to the screen chamber. There are specially designed tools that are used in this chamber to remove the plastic, coarse particles, metals, and other contaminants from the wastewater to protect the equipment for further processing and to protect the water passing through the pipes. This process or treatment is known as elementary treatment in the water treatment process.

2: The sewage waste and effluent are moved to an equalization tank after the elementary procedure is completed. The equalization tank is used to keep the sewage and effluent combination flowing at a consistent and uniform rate. It can also be used to homogenize sewage and effluent mixtures. The velocity of detonation of wastewater has been reduced from 10% to 20% thanks to aeration in the equalization tank.

3: After the raw sewage and industrial effluent have been homogenized, they are sent to the Membrane Bioreactor. Membrane Bioreactors are used in biological therapy, either secondary or primary. The Membrane Bioreactor, like the Activated Sludge Tank, features an aeration system. The aeration system in the Membrane Bioreactor is constantly employed to give continuous circulation to the sewage in order to maintain the level of dissolved oxygen in the chamber. A microbe, also known as a bio layer, forms a layer of plastic media on which adequate aeration can boost the microorganism's effectiveness, hence increasing the efficiency of the Membrane Bioreactor.

Treated water parameters of MBR plants

MBR facilities are made by combining the biological process with membrane filtration, which has several advantages over traditional technologies like activated sludge. MBR is commonly used for municipal and industrial wastewater treatment.

1: COD removal

Due to the high number of microorganisms in MBRs, better degradation in a given time span of pollutants take place. COD removal can be increased to 96 to 99% in MBRs.

2: Sludge yield

At sludge loading rates of 0.01 kg COD, little or no sludge is formed.

3: Nutrient removal

MBR encourages the retention of solids, which improves bio-treatment. It also encourages the development of slower-growing microorganisms, particularly nitrifying ones, which makes them more efficient at removing nitrogen (nitrification).

MBRs can achieve the following effluent quality on a constant basis:

|

TSS |

< 1mg/L |

|

BOD |

< 3mg/L |

|

NH3-N |

<0.5 mg/L |

|

Total Nitrogen |

<3 mg/L |

|

Total phosphorus |

<0.05 mg/L |

|

Turbidity |

<0.2 NTU |

MBRs create consistent high-quality effluent that may be reused in a range of municipal, industrial, and commercial applications, as well as in ecologically sensitive regions. They can be employed in small to large-scale operations, and the high-quality effluent produced makes them ideal for reuse applications.

MBR effluent is also a great supply of water for reverse osmosis, which may be used to create higher-quality water for groundwater recharging or industrial clean water reuse.

What can we offer?

Netsol Water is one of the leading water and wastewater treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines like MBR, which not only turns your wastewater into usable water but also acts as a savior of Mother earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.