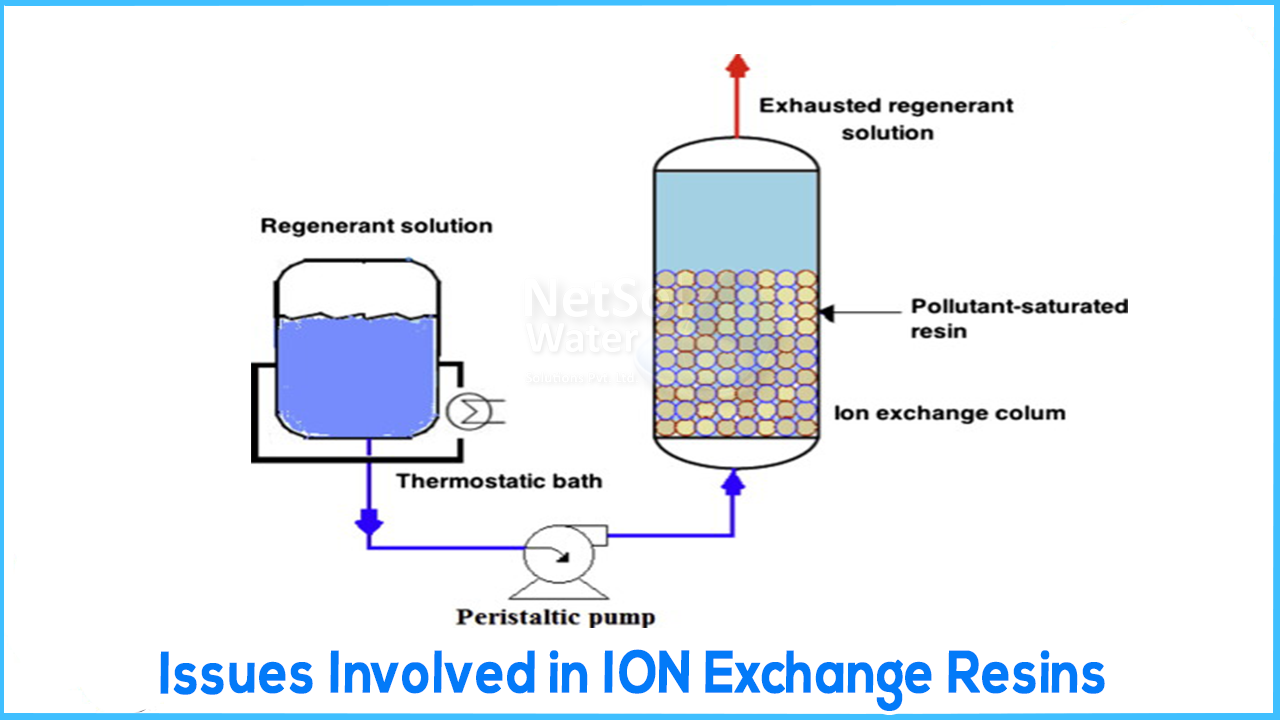

Ion Exchange Resin (IX) frameworks can provide an effective solution for a variety of demineralization, cleansing, and wastewater treatment requirements. They are made up of polymer arrangements to which ionic "useful gatherings" of positively or negatively charged molecules (cations or anions) are permanently bound. These practical gatherings have a large negative or positive charge, allowing them to effectively motivate counter particles or particles with opposing charges. As a fluid stream moves through the IX sap, the counter particles can be replaced by particles of comparable charge.

COMMON ISSUES INCLUDED IN ION EXCHANGE WITH A SOLUTION

- 1. Resin Fouling: IX saps function by arranging electrically charged particles in such a way that they can be traded with pollutant particles in the feed arrangement. In any case, a few toxins can bind to the sap, preventing further particle trade responses. Except that if this is remedied, the contaminated pitch will reconsider quality, and ionic practical gatherings cannot be easily re-established through a typical recovery cycle. Toxins that commonly contribute to sap fouling include:

- - Aluminium

- - Hardness Precipitates

- - Iron

- - Manganese

- - Microbiological

- - Oil

- - Organics

- - Silica

- - Sulphate

Solution:While tar fouling reduces IX framework execution, it is generally expected to be reversible with appropriate remediation measures. These should be specific to the foulants present, but in general, caustics are used to remove foulants from anion gums, and acids or solid lessening specialists are used to remove foulants from cation saps. Surfactants are commonly used to clean oil from fouled gums, but it is critical to use caution when selecting a surfactant that will not foul the gum. Natural fouling is both extremely common and relatively difficult to address. Natural fouling protection systems include prechlorination and explanation, enacted carbon filtration, the use of a multistep IX with feeble and solid base gums, and the use of claim to fame IX pitches.

- 2. Thermal Resin Degradation: Extremely high or low temperatures can permanently jeopardise the viability of IX saps. Warm debasement, in the long run, changes the pitch's atomic design to the point where it is no longer capable of tying with the practical gatherings of particles that are critical to the IX response, resulting in compromised functional execution and shorter item life.

Solution: Because the IX pitch limit has an inverse relationship with temperature, consider the suggested functional temperatures and other interaction conditions to limit warm corruption over time. Although cation gums are more resistant to heat deterioration than anion tars, both can withstand brief exposures to high temperatures for sanitization or other purposes. While delayed exposure to extreme temperatures usually implies a shorter useful life for IX saps, the costs of more successive pitch substitution may not always offset the costs of energy and hardware required for temperature control.

- 3. Resin Oxidation: IX pitches are crosslinked polymers that can withstand exposure to a variety of substances. Overall, they are ineffective against oxidising specialists such as nitrates, peroxides, halogen mixtures, chlorine, and hypochlorite compounds, among others. When oxidants are present in a feed stream, they degrade IX tar polymers, causing them to become misshapen and reduced over time. This compaction impedes fluid progression through the sap bed, which can call into question the overall sufficiency of the IX unit and result in clashing gushing quality due to directing in the gum bed.

Solution: While oxidation harm to IX pitches cannot be avoided, it can be delayed through various pre - treatment measures. Normal oxidation corruption deterrent measures incorporate the use of enacted carbon filtration, bright light, or substance pre - treatment through the use of a diminishing expert.