Is it possible to chlorinate sea water?

Although the Earth is covered in water, just 3% of it is fresh. For many sectors, this is acceptable because seawater may be used for a variety of purposes. One of the most common applications is as a coolant. The difficulty is that algae in seawater can generate a slew of issues if chemical dosing isn't done properly. When dealing with algae and other marine life growth, many people resort to chlorination treatments to clear the water of unwanted organisms. Chlorination of seawater is a typical approach for dealing with this problem.

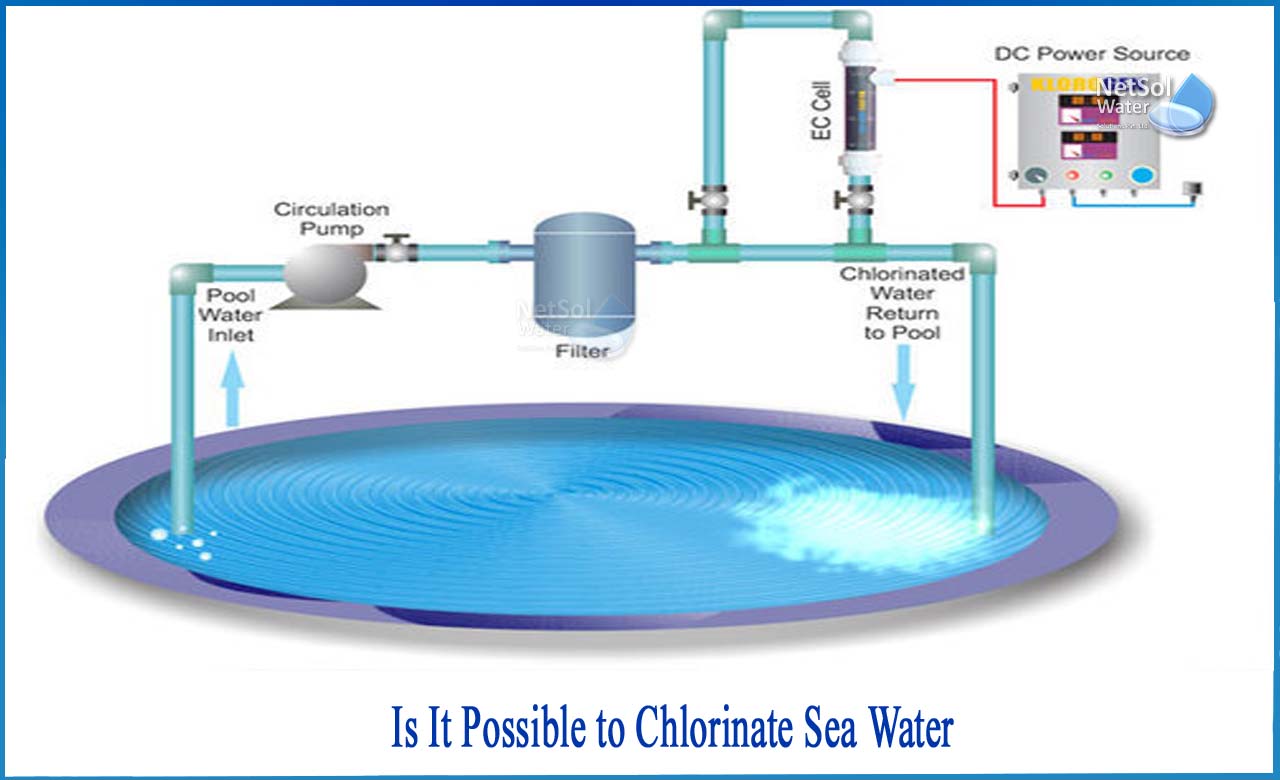

Chemical dosing systems

Chemical dosing systems can provide a constant supply of chlorine to the water, which is beneficial for limiting the growth of marine life in the water. When the chemical dosing ingredients are mixed with seawater that has undergone an electrolysis procedure, they become active. These systems must be continually monitored.

The two primary components:

- Chlorine

- Sodium hypochlorite

A sodium ion and a hypochlorite ion combine to generate sodium chlorite. When you put this in water, it turns into chlorine dioxide, which is commonly known as bleach.

Sodium hypochlorite is not the same as elemental chlorine, and the former is utilised as a disinfectant in a variety of situations.

Water treatments for sea water

1: Electrolysis of any sodium chloride detected in the water is used in seawater treatment systems that use chlorination. The seawater is forced through an electrode-lined area. The chemical reactions that produces chlorine dioxide begin when current is applied to the electrodes. The amount of chlorine in the water is lowered as any organic stuff is oxidised by chlorine dioxide.

2: To get the appropriate chlorine content in the water, an analyser in the water must be utilised. Another option is to make hypochlorite from scratch. Hypochlorite generators are used in some industrial water treatment systems.

3: Booster pumps are used to boost the pressure of seawater. Effective contaminant removal measures must be utilised before it is allowed to enter the system.

4: These systems also use electrolysis to convert sodium chloride, but the end product is sodium hypochlorite, which is then converted to chlorine dioxide. The rise in temperature caused by the chemical reaction, as well as the fall in seawater level, are two potential difficulties.

5: Another option is to directly add sodium hypochlorite into the water. This is one of the water treatment items that may be kept in the refrigerator and used as needed. Because sodium hypochlorite does not need to be made, this is one of the easier types of chemical dosing.

6: The storage tank must be specifically built to handle sodium hypochlorite. Shock chemical dosing is a term used to describe this type of treatment. This method can also be used to remove any trapped hydrogen from water.

7: Positive displacement or centrifugal pumps can be used to inject sodium hypochlorite. The former is preferable if the amount of water to be treated is modest. Centrifugal pumps are more efficient when the amount of water to be treated is big.

8: Diffusers can make the process move more easily and make the injection of sodium hypochlorite more uniform, regardless of the type of pump used in this type of chemical dosing.

9: Carbonates and hydroxides are generated in the presence of positive ions in the water. To make the hypochlorite, electrolysers can be utilised.

10: Acid-based systems require an additional tank. Before being used for industrial purposes, the water must pass through a tank where the acids can be neutralised. Because the acids used to make hypochlorite are caustic, the tanks must be able to handle them.

Conclusion

Chlorine dioxide is a potent oxidising chemical that can be particularly successful at killing algae and other harmful marine life in saltwater and drinking water. When dealing with salt water, electrolysis of the sodium chloride or addition to acid to make chlorine dioxide, an excellent disinfectant, is required to convert sodium chloride to sodium hypochlorite. This is why chlorination is an efficient method for cleaning saltwater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.