How to treat wastewater from paper mills using Electrocoagulation?

Paper production basically depends on natural resources, such as water, forests, agricultural products, and fossil fuels. The manufacturing of pulp and paper requires a significant amount of fresh water. These procedures include the processing of the wood, pulping, washing of the pulp, and bleaching, all of which produce a significant amount of effluent, and have negative environmental effects.

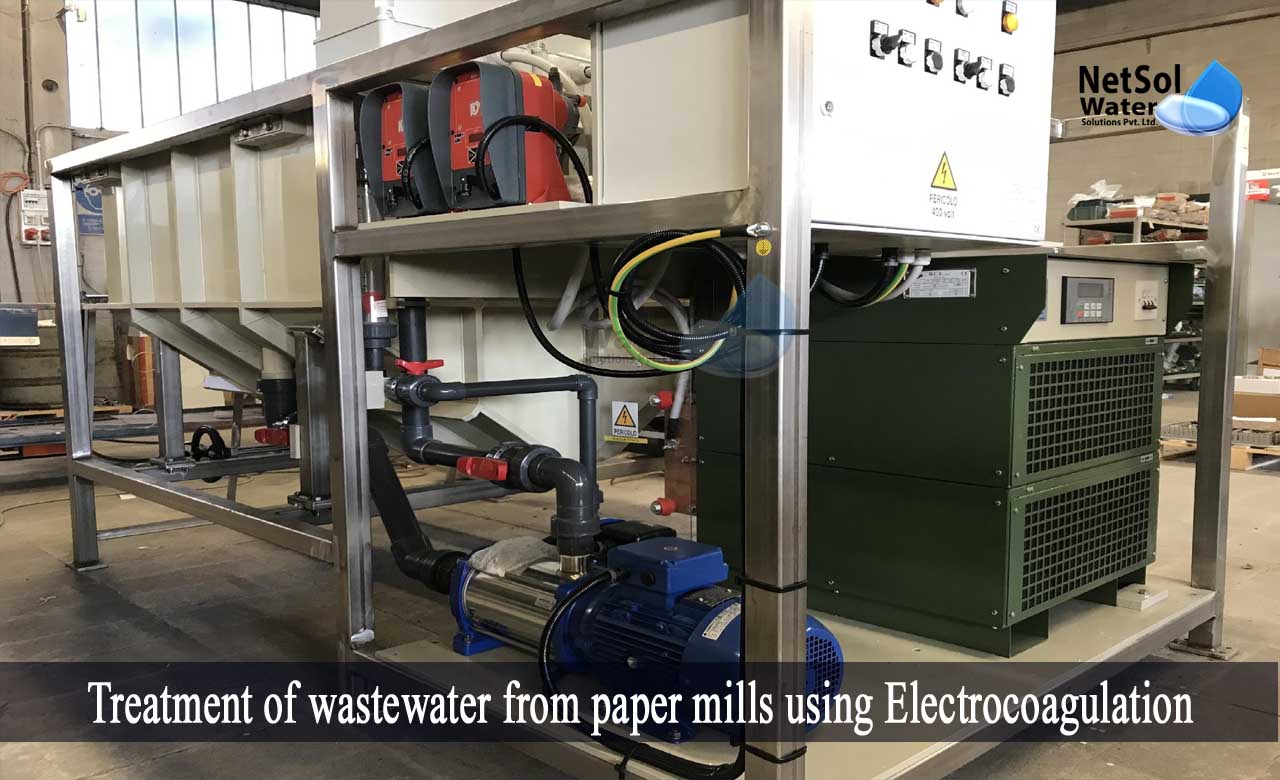

To treat effluent generated from paper mills, various technologies are utilized, which include electrocoagulation for efficient contaminant removal.

Technologies for Effluent treatment in Indian paper mills

At its treatment facilities, the Indian paper industry mostly uses primary (sedimentation, floatation) and secondary two-step treatment (activated sludge, anaerobic or aerobic process). These procedures fall short of the requirements for fully degrading bio-refractory chemicals, COD, and colour. They also have some disadvantages, like a high cost of treatment and a significant volume of generated sludge, which could lead to secondary contamination.

Thus, it is imperative to either stop the production of these chemicals or to enact appropriate strategies, to hasten their breakdown in plants. To remove these pollutants from wastewater, a reliable treatment facility is increasingly necessary.

Advanced wastewater treatment techniques should be used to solve these specific problems-

To handle these water conditions and optimize this effluent for environmentally safe release or reuse, priority must be given to modern wastewater treatment techniques. These workable solutions are specifically offered to paper firms, to help them harness the wastewater resources from their paper mills, in a sustainable manner while adhering to constantly evolving regulatory requirements.

Treatment of wastewater in paper mills using electrocoagulation

Due to its distinct advantage over chemical and biological treatment facilities, the electrocoagulation (EC) method has recently drawn the attention of several researchers, from all over the world. Environmental compatibility, correct set-up, quicker reaction times, little chemical requirements, and minimum sludge generation, are all characteristics of the EC process.

Electrons, a clean reagent, are the major acting reagents in this process. Due to the amount of wastewater and contaminants produced by pulp and paper plants, modular wastewater treatment conducted on site is frequently necessary.

Stages of effluent treatment in paper and pulp mills

According to the pulp and paper mill's treatment flow rate, common treatment technologies include primary treatment for the removal of larger suspended solids and particles, followed by coagulation and flocculation, using either specialized electrocoagulation or specialized flocculants.

Tertiary treatment has also been used with biological treatment. This comprises advanced oxidation, activated carbon, and membrane treatment systems, which can produce water of higher quality that can be disposed sustainably, or used efficiently in paper mill facility operations.

Methods to reduce water usage in paper mill operations

If you are looking for ways to reduce the amount of water your paper mill facility uses, we have listed a few noteworthy ideas that your facility can use, to improve everyday operations and lower overall operational costs.

- Audit of the plant's water treatment process.

- Regular maintenance of plant systems.

- Integration of cutting-edge modular treatment options.

Conclusion

For pulp and paper factories, reducing water use is a continuous effort that calls for a commitment to sustainability. However, if this commitment is effectively implemented over time, throughout these factories, it will result in lower overall operational expenses for the business, and allow these facilities to comply with constantly changing requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.