What are clarifiers in wastewater?

Dissolution rate, confinement periods, and other factors have been summarised for convenience. Of course, each wastewater treatment facility is unique, with potentially significant variances between municipal and industrial wastewater systems. Wastewater clarifiers are costly to operate, but utilising them wrong may cost you far more than a punishment issued by regulatory organisations.

If adequate standards and procedures are not followed, an entire community may be plagued by polluted drinking water, which can spread diseases such as cholera, diarrhoea, typhoid, polio, and others.

Which is why wastewater operators must understand the distinction between primary and secondary clarifiers. It's easy to confuse the two, but there is one distinct physical trait that distinguishes them.

Clarifier efficiencies are affected by many factors, including:

1. The type and source of solids in wastewater: Solids from a substantial industrial contribution to a municipal wastewater plant will have considerably different properties than solids from a "typical" municipal plant.

2. The wastewater stream's transit duration and temperature will have a significant negative influence on the solids. Higher wastewater temperatures and longer transit periods increase the chance of septic contamination. Due to gas bubble attachment, septic wastewater slows the settling rate of particles, increasing the buoyancy of the solids and keeping them suspended.

3. The rate of hydraulic loading on the clarifier: Solids settling will be reduced as loading rates increase.

4. The clarifier's maintenance status: There can be considerable performance discrepancies between well-maintained and poorly-maintained clarifiers.

5. Waste activated sludge, digester supernatant, and dewatering centrate/filtrate streams all have a detrimental influence on solids settling. Furthermore, when wastes are circulated across a treatment plant, particle size decreases, increasing surface area and reducing the rate at which microscopic particles settle.

6.Detention time in the clarifier should be between 2.0 and 3.0 hours. Solids carryover will occur if the detention duration is too short, while septicity will grow if the detention time is too lengthy. 3 hours of retention, in my opinion, is excessive and would certainly enhance septicity in the sludge during the warmer months.

>The first clarifier process:

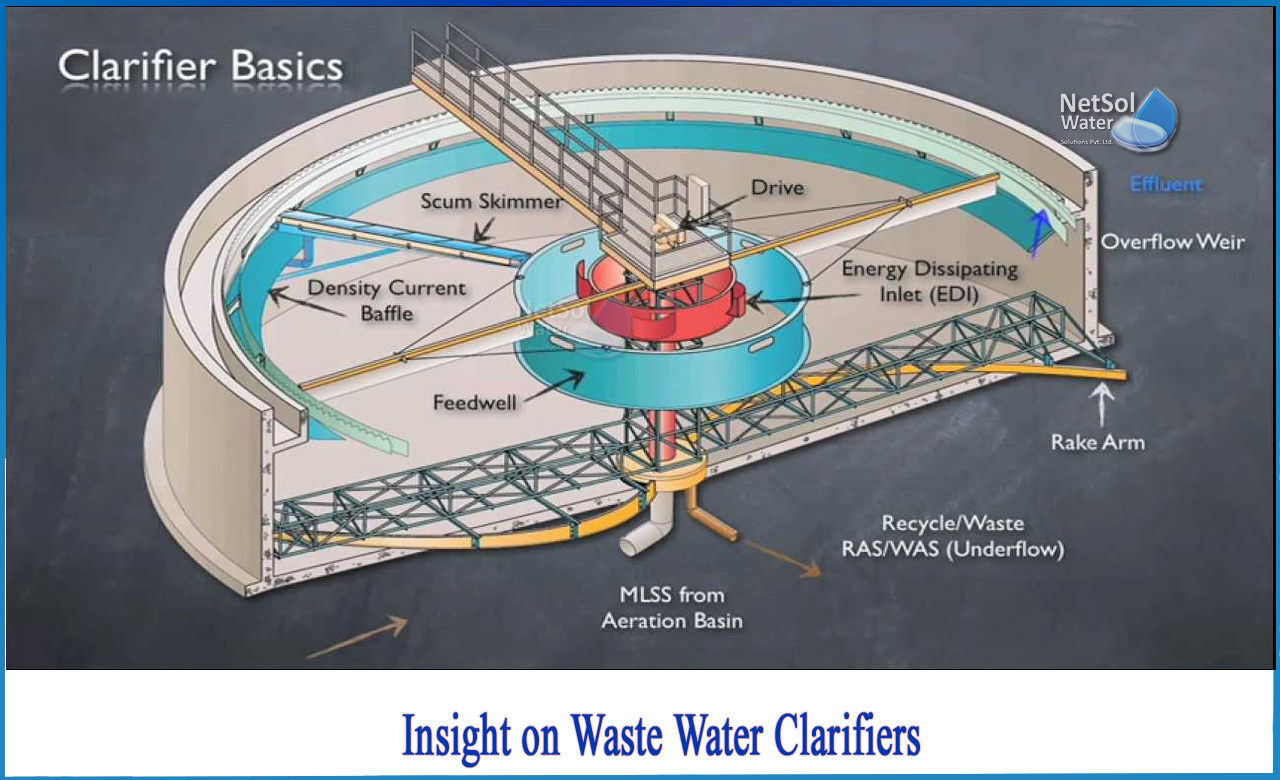

The primary clarifying process, also known as sedimentation, is the removal of inorganic solids prior to biological treatment. The following is a step-by-step procedure:

1. Water is introduced into the clarifier tank.

2. Skimmers remove the inorganic materials (scum) floating on the surface.

3. A rake collects the settling sludge at the bottom, which is subsequently removed by the sludge removal system.

4. Biologically treated effluent flows out of the clarifier via a weir.

A good primary clarifier should remove 90 to 95 percent of the sludge, 40 to 60 percent of the scum, and 25 to 50 percent of the Biological Oxygen Demand (BOD).

What factors affect primary clarifier efficiency?

The goal of any primary clarifying procedure is to eliminate as much trash as possible, however various circumstances might impede the optimum outcomes.

• Hydraulic overload and underload: Overload reduces hydraulic detention time, while underload stops the machine from operating at maximum capacity, wasting usage and energy.

• Sludge accumulation reduces tank volume.

• Highly concentrated waste streams: These waste streams have a high solid count and a high BOD level. In this circumstance, the clarifier will struggle to handle its sludge volume and will not function correctly.

The first clarifier process should be managed properly to guarantee a seamless transition to the secondary clarifier process.

>The process of secondary clarifier:

The secondary clarifier is a circular basin that holds effluent from the activated sludge process. The steps are as follows:

1-The biomass of microorganisms settles to the bottom in the form of activated sludge.

2-After settling over a period of time, this biomass of microorganisms is returned to the first aeration tank.

3-This cycle repeats until only clean water is left.

4-The clean water that remains flows to the top of the clarifier and is further sent for disinfection.

More often than not, there is excess biomass after each settling process is completed. It has to be thickened and pumped into a digestion tower alongside the primary sludge, without oxygen. This produces methane gases which quickens the sludge removal process.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.