What does a membrane bioreactor do?

Membrane Bioreactors are treatment methods that combine a perm-selective or semi-permeable membrane with a biological process. It combines a membrane technique, such as microfiltration or ultrafiltration, with a suspended growth bioreactor, and is currently commonly used for municipal and industrial wastewater treatment with plant sizes ranging from 10,000 to 80,000 population equivalents. Because it is a highly technological solution, it needs professional design and skilful labour. Additionally, it is a pricey but effective therapy option. It is feasible to improve outdated wastewater treatment plants using MBBR technology.

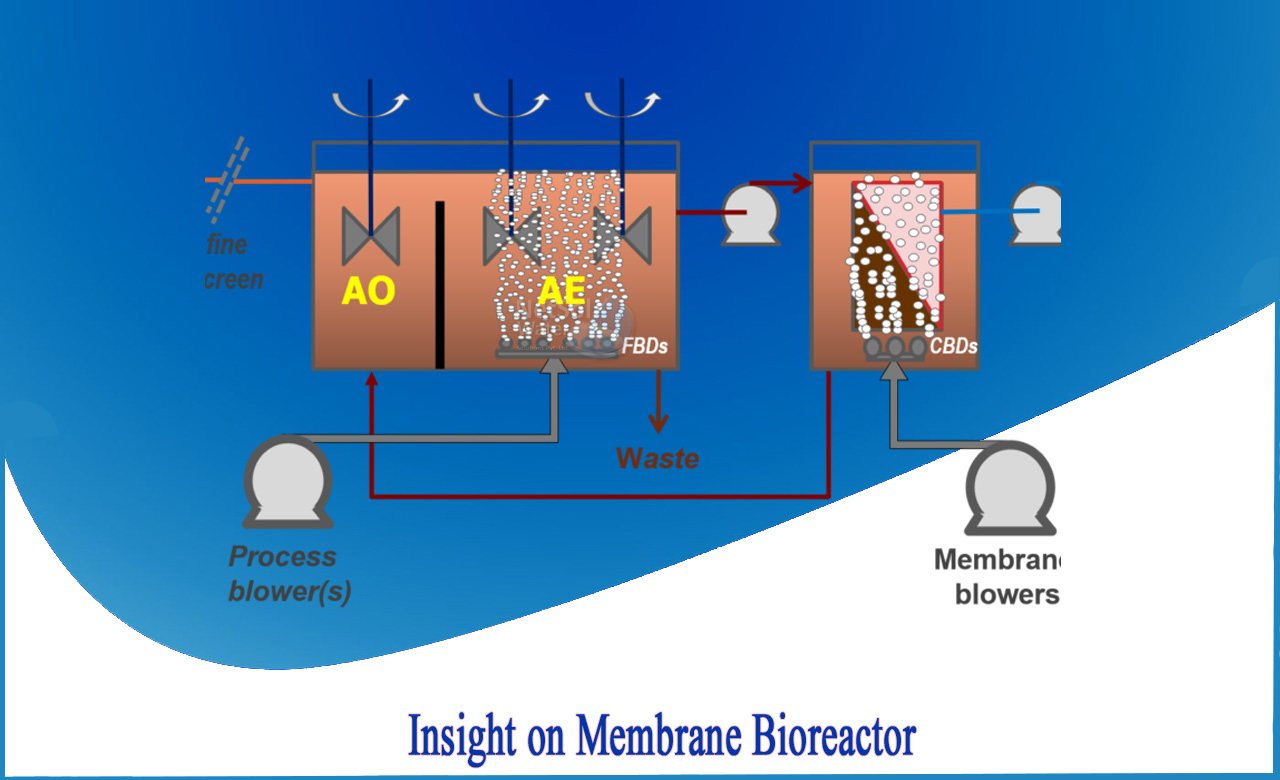

Membrane Bioreactors combine traditional biological treatment procedures (such as activated sludge) with membrane filtration to give an improved level of organic and suspended solids removal. When properly developed, these systems may also enable enhanced nutrient removal. The membranes of an MBBR system are immersed in an aerated biological reactor. The porosities of the membranes range from 0.035 microns to 0.4 microns.

Such level of filtration permits high-quality effluent to be pulled through the membranes, obviating the need for sedimentation and filtration techniques commonly employed in wastewater treatment. Because sedimentation is no longer required, the biological process may run at considerably greater mixed liquor concentrations.

This significantly decreases the amount of process tankage required, allowing many existing facilities to be updated without the addition of additional tanks. The mixed liquid is generally kept in the 1.0-1.2 percent solids range to enable adequate aeration and scour around the membranes, which is four times that of a traditional plant.

Membrane bioreactors' predictive validity

Membrane Bioreactor systems are used in municipal and industrial wastewater treatment plants. Furthermore, MBBRs can be used to remediate landfill leachate. It is a high-tech system that needs expert design and skilled operators.

Advantages of membrane bioreactors

- Secondary condensers and tertiary filtering operations are removed, resulting in a smaller plant footprint. In some cases, the footprint can be lowered even further by eliminating or minimising additional process units like as digesters or UV disinfection (dependent upon governing regulations).

- Could be designed to prolong sludge age, thus lower sludge accumulation.

- Higher effluent quality

- More loading rate capability

Membrane bioreactor’s health implications

MBBR system operation and maintenance are often performed by expert labourers who must be adequately trained in order to avoid any health dangers. The biological system's sludge should be dewatered (through mechanical dewatering or a drying bed) and burned, with the ashes placed in a regulated landfill.

Fouling

Because modern systems are chemically maintained, it is not essential to remove the membranes from the membrane tank. Organic fouling may be removed with sodium hypochlorite, whereas inorganic fouling can be treated using oxalic acid.

One of the main constraints of the MBBR process is fouling, which happens as a result of interactions between the membrane and the mixed liquid. Membrane fouling in MBBRs is a very complicated process with numerous interconnections among its sources, and it is extremely difficult to localise and describe membrane fouling precisely.

The following are the most important reasons of membrane fouling:

- Adsorption of macromolecules

- Growth of biofilms on the membrane surface

-Precipitation of inorganic matter

- Aging of the membrane

Membrane bioreactor management

Typically, MBBRs need chemical maintenance cleaning once a week for 30–60 minutes, and recovery cleaning once or twice a year when the filtering is no longer durable.

The term "irrecoverable fouling" refers to a deposit that cannot be removed using existing cleaning procedures. This fouling accumulates over time and finally decides the membrane life-span. All operation and maintenance duties must be completed by skilled staff.

For more information, contact Netsol water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.