Why Commercial Water Softener are used in power plants?

The mineral balance of incoming water to industrial systems is critical to the effective functioning and maintenance of costly machinery. It's also critical to deliver a consistent end result. To keep the industrial process running, industrial water softeners remove excess minerals like calcium and magnesium to a predetermined and monitored level.

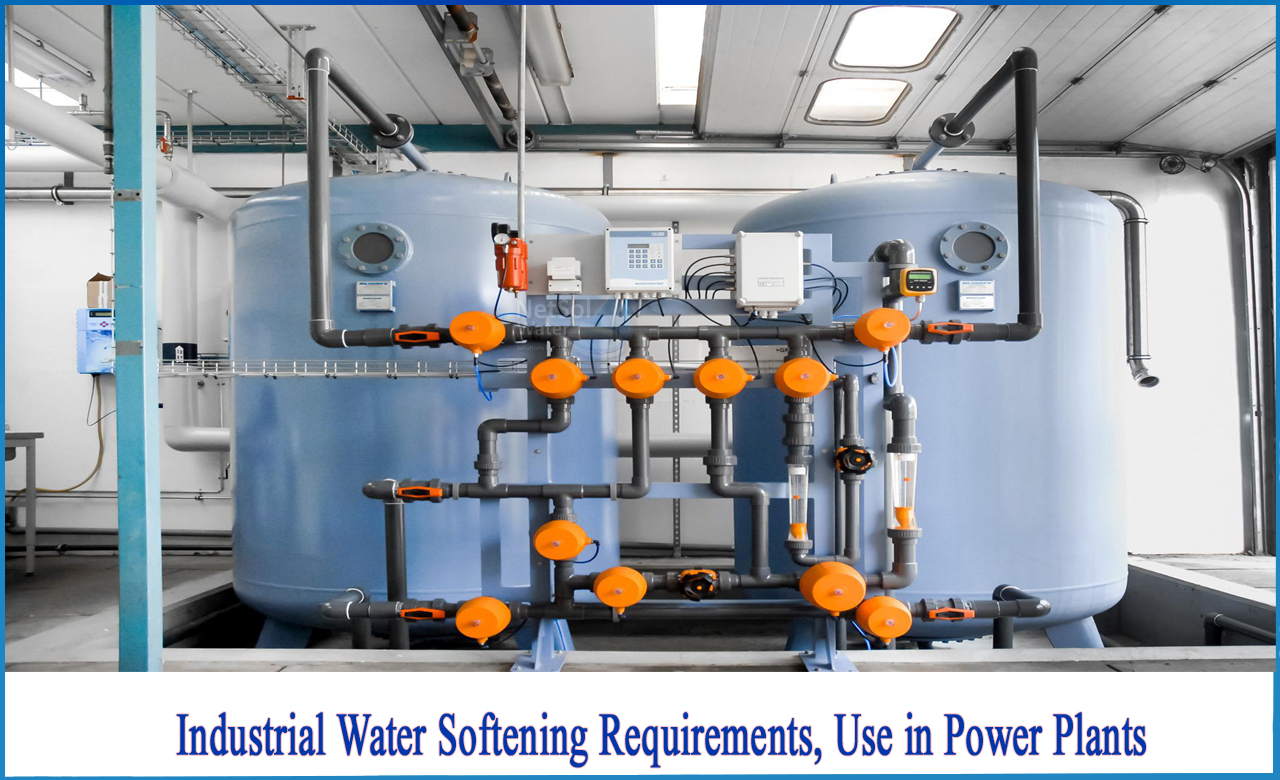

Water softening for industrial uses necessitates the passage of incoming water through a porous resin bed. This resin resembles microscopic plastic beads in appearance and consistency. Each small bead has been made and handled in such a way that it is extremely permeable. The surface area is also permanently chemically changed to make the problematic minerals very appealing.

Minerals with an electron charge of two or higher, such as calcium and magnesium, have an affinity for the resin's surface sites. Other minerals with a comparable valancy can be extracted as well. The correct operation of the water softening system necessitates a thorough examination of the entering water.

The water softener vessel, which is filled with the resin bed, receives the incoming water. The water's velocity slows as it spreads across the bed's larger surface area and passes through the millions of tiny beads. The minerals in the water are drawn to the resin surface regions during this process. The water then exits the resin bed, free of the mineral-laden water and with a minimal loss in hydraulic head pressure. The hardness minerals in the water are captured by the resin bed.

The efficacy of the water softener steadily decreases as the surface area of each bed in the resin is occupied by minerals. Equipment to regenerate these resin beds is required as part of a complete industrial water softening system. In most cases, a duplicate resin bed can be activated to give the primary resin bed time to refresh. After the water has been transferred to the second bed, the first bed can be regenerated.

Why is soft water required in power plants?

In power plants, to maintain optimum operation of steam generation systems, high purity feed water is essential in the steam boiler sector. Due to fewer blowdown requirements, high purity feed water decreases the consumption of boiler chemicals (reducing blowdown frequency by as much as a factor of 10).

Reduced blowdown frequency translates to decreased fuel expenditures. Due to a lower concentration of contaminants in the boiler feed water, scale deposition on heat transfer surfaces is decreased. The decreased impurity level also lessens the rate of corrosion in the boiler. Turbine blade erosion is decreased when a boiler is used to power a steam turbine because the steam produced is of better quality.

Conclusion:

With just modest final polishing by ion exchange resins, the treatment system can be employed to treat boiler feed water. This alternate separation procedure eliminates the need for pretreatment and can significantly reduce the amount of chemicals used in regeneration, lowering the amount of spent regenerant and associated expenses.

For proper functioning of power plants, water softening is essential. Get the water quality checked and do the necessary steps for installation of water treatment system including water softener from Netsol water solutions for industrial use including power plants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.