What are stages involved in the industrial wastewater treatment?

Approximately 80% of all wastewater is now dumped into the world's waterways, posing health, environmental, and climate-related risks.

According to estimates, high-income countries' wastewater treatment capacity is currently 70%, whereas low-income countries' treatment capacity is only 8%. Furthermore, with increased wastewater generation, urbanization exacerbates the problem. Untreated effluent discharge into water bodies not only causes eutrophication and human health problems, but it also contributes significantly to GHG emissions in the form of nitrous oxide and methane. Untreated sewage emits three times the amount of pollutants as typical wastewater treatment.

In terms of cleanliness and disease control, proper wastewater management and sewage systems are critical. The development of a system to handle communal wastewater and sewage is critical. Wastewater can otherwise damage the surrounding environment and drinking water supply, increasing the risk of disease transmission.

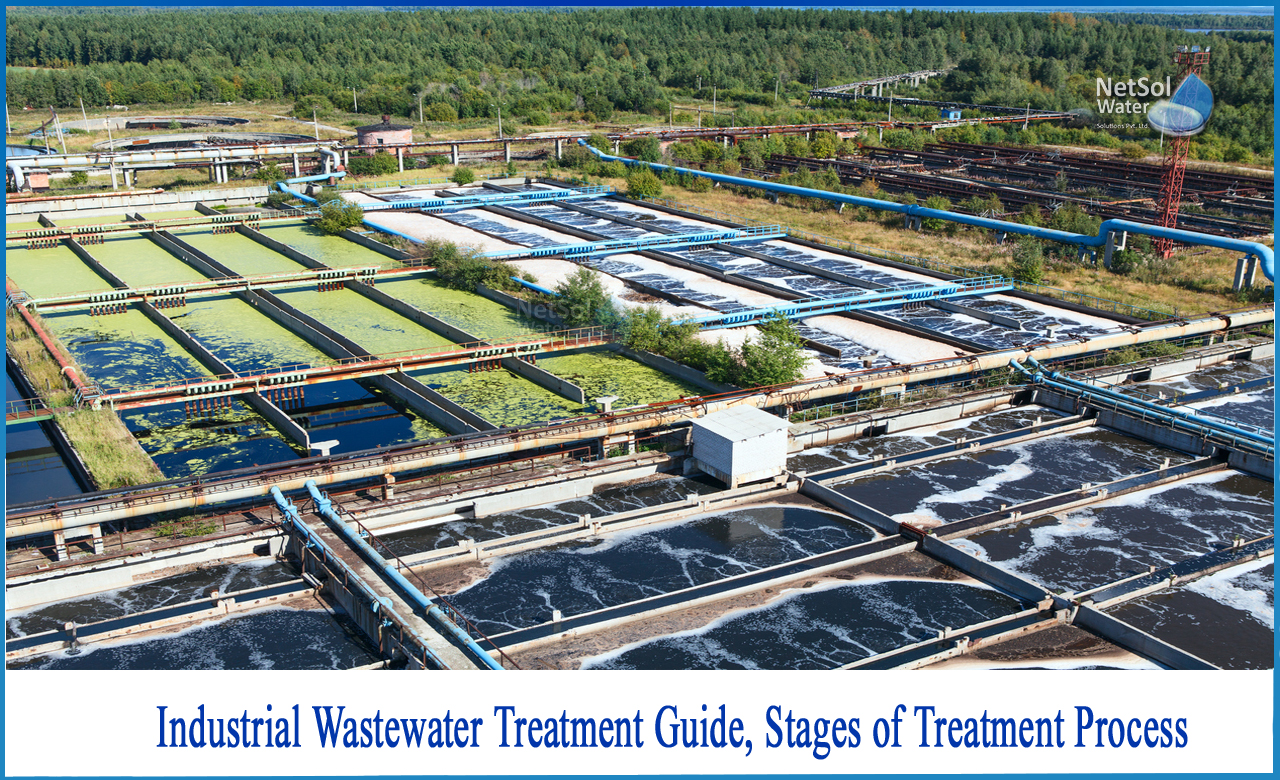

Stages of Wastewater Treatment

1: Preliminary Treatment - Pre-treatment is required to ensure that nothing interferes with the upcoming treatment. It can prevent clogs in raw water lifting systems and pipelines, as well as abrasion in other treatment equipment’s and the removal of anything that can interfere with later treatment. They can also help to increase the life of sanitation infrastructure by reducing abrasion of mechanical parts.

Pre-treatment has several advantages, including minimal capital expenditures and low to moderate operational expenses. This is combined with a lower risk of compromising future conveyance and/or treatment technologies.

2: Primary Treatment - The goal of primary treatment is to remove floatable organic and inorganic pollutants by sedimentation and floatable organic and inorganic solids by skimming. During primary treatment, about 25% to 35% of the incoming biochemical oxygen demand (BOD), 50 to 70% of the total suspended solids (SS), and 65 percent of the oil and grease are removed.

3: Secondary Treatment - The goal of secondary treatment is to get rid of any remaining organics or suspended materials. Thus, there is the use of aerobic biological treatment techniques to remove biodegradable dissolved and colloidal organic materials. Aerobic biological treatment involves aerobic microorganisms (mostly bacteria) metabolizing the organic content in the wastewater and creating additional microorganisms and inorganic end-products in the presence of oxygen.

4: Tertiary Treatment - Specific wastewater elements that cannot be eliminated by secondary treatment are removed using tertiary and/or advanced wastewater treatment. Individual treatment techniques can remove nitrogen, phosphorus, extra suspended particles, refractory organics, heavy metals, and dissolved solids.

Technologies in Wastewater Treatment

Membrane-based techniques such as ultrafiltration (UF) and reverse osmosis (RO), as well as disinfection using ultraviolet (UV) light or ozone, can all be used to reuse potable water. In recent years, there have found new uses in industry. Electrodialysis, ceramic membranes, and enhanced oxidation are among the other techniques being used in unique ways to enable wastewater reuse. The industry has divided wastewater reuse into indirect (IPR) and direct (DPR) reuse for potable applications.

What is Wastewater Recovery?

Water reuse is a type of wastewater recovery in which water is retrieved for agricultural and golf course irrigation instead of being dumped into the environment. This is in line with a rising trend to see wastewater treatment plants as resource recovery centers rather than wastewater treatment plants. A crucial potential is to recover the water, energy, minerals, and other valuable components embedded in wastewater.

Bio-gas, fertilizer, paper, metals, polymers, and, perhaps most crucially, a source of 'new' water, are all examples of commercially viable resource recovery from wastewater.

Conclusion

To preserve human health, the environment, and nearby water quality, wastewater treatment, collection, and discharge are required. Wastewater must first be collected from sewer networks serving residential, municipal, commercial, and industrial properties before it can be treated.

The treatment of wastewater and industrial wastewater is changing. It was originally intended to purify wastewater before a cleaned effluent could be safely discharged into the surrounding region. Wastewater is now viewed as a valuable resource for generating electricity, fertilizers, and water for irrigation, industry, and even drinking.

What can we offer?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, ETP and RO Plant manufacture, among other services. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish. We are committed to providing our valued customers with hands-on service, expert counselling, and training.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.