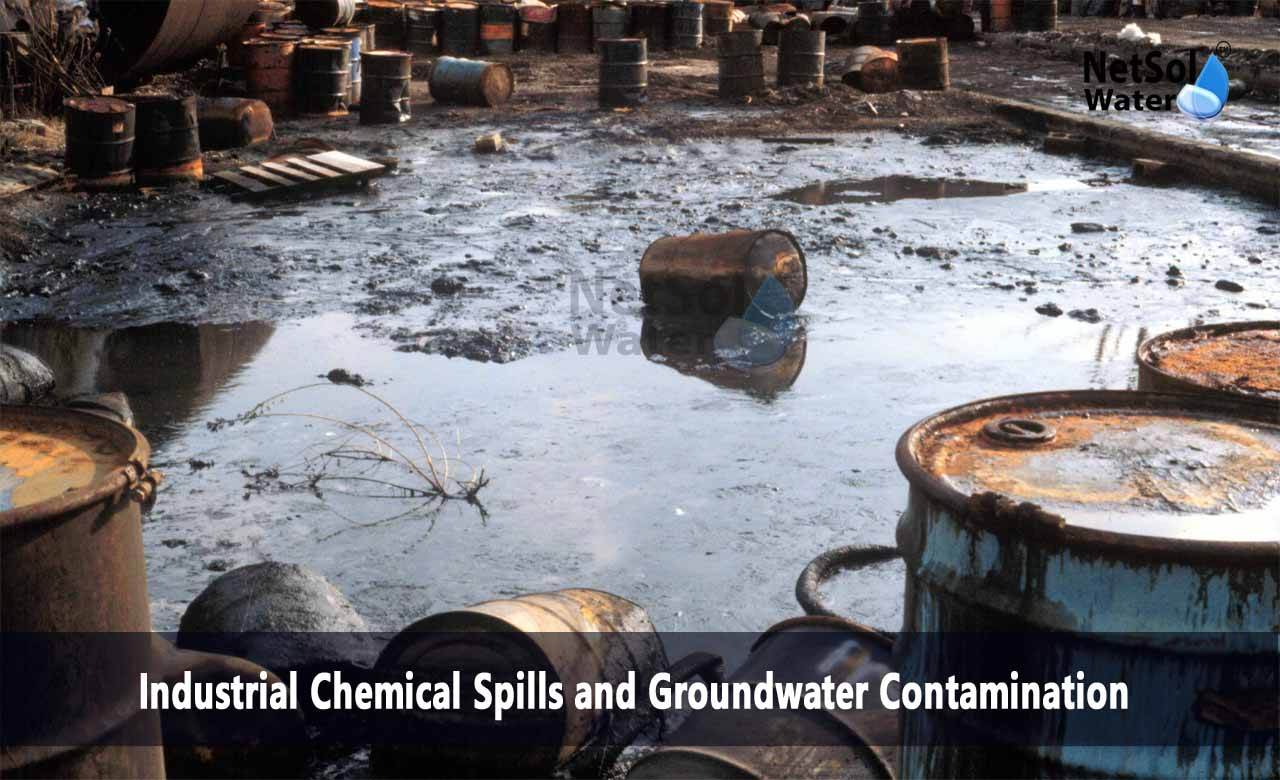

Industrial Chemical Spills and Groundwater Contamination

Water sustains life on Earth. Yet beneath the surface waits a growing environmental crisis that threatens this precious resource. Industrial chemical spills create lasting damage to groundwater systems worldwide. These contamination events pose serious risks to human health and ecosystems. The impact extends far beyond the immediate spill site because groundwater flows through underground networks that connect different regions. This interconnected nature means that chemical contamination from industrial sites can spread to drinking water sources miles away. Communities often discover the problem only after people start experiencing health issues. The growing frequency of industrial chemical spills demands immediate attention from environmental agencies. This challenge requires better prevention strategies and improved cleanup methods. The future of clean groundwater depends on how we address industrial chemical contamination today.

The Science Behind Chemical Contamination

Understanding how industrial chemicals interact with groundwater helps explain their devastating effects. When chemical spills occur the contaminants seep through soil layers until they reach groundwater aquifers. Different chemicals move through soil at varying speeds based on their physical properties. Some chemicals dissolve in water while others form separate liquid phases. The geological features of the contaminated site influence how chemicals spread through groundwater systems. Sandy soils allow faster movement while clay layers slow contamination spread. Temperature changes affect chemical behaviour in groundwater. The complexity of these interactions makes tracking and cleaning up industrial chemical spills challenging. Groundwater monitoring reveals how contamination plumes expand over time. This knowledge guides cleanup strategies and helps predict future contamination risks.

Prevention and Safety Protocols

The best solution for industrial chemical spills starts with prevention. Manufacturing facilities need comprehensive safety systems to protect groundwater resources. This includes proper chemical storage containment areas and regular equipment maintenance. Worker training plays a central role in preventing spills. Emergency response plans prepare facilities for worst-case scenarios. Modern monitoring technology helps detect leaks before they become major spills. Insurance requirements motivate companies to maintain high safety standards. Regular site inspections identify potential problems early. Environmental regulations set clear standards for chemical handling. Safety protocols evolve as we learn from past industrial chemical spills. Documentation requirements ensure facilities track their chemical usage. Building design incorporates spill prevention features. Multiple containment layers provide backup protection. These preventive measures cost less than cleaning up contamination.

Environmental Impact Assessment

Let us look at how industrial chemical spills affect entire ecosystems. The damage extends beyond immediate contamination sites.

Soil Degradation: Chemical spills change soil chemistry. This disrupts plant growth and soil microorganisms. The altered soil conditions affect local vegetation patterns. Recovery takes years even after cleanup efforts finish.

Aquatic Ecosystems: Fish populations decline in contaminated waterways. Chemical exposure affects reproduction rates. The food chain suffers as contamination moves through different species. Some aquatic plants disappear from affected areas.

Long-term Effects: Environmental damage can last for decades. New problems emerge as chemicals break down over time. Future generations inherit these contaminated sites. The full impact of industrial chemical spills takes years to understand.

Cleanup Methods and Restoration

Each contamination site presents unique challenges. Let us explore the main approaches to groundwater restoration.

Extraction Systems: Pump-and-treat methods remove contaminated water. Treatment plants clean the extracted water. This process continues until contamination levels drop. New extraction technologies improve efficiency.

Bioremediation: Natural bacteria break down some chemical contaminants. Scientists enhance this process with specialized microorganisms. This method works well for organic chemicals. The treatment time depends on contamination levels.

Chemical Treatment: Neutralizing agents counteract specific contaminants. This approach requires careful planning. Different chemicals need different treatment methods. Regular testing confirms treatment effectiveness.

Conclusion:

Industrial chemical spills transform groundwater systems in ways that threaten public health and environmental stability. Every community needs to understand these risks. Your involvement makes a difference in protecting water resources. Contact environmental protection agencies to learn about local groundwater quality. Join community efforts to monitor industrial activities near water sources. Together we can prevent future contamination events.

Want to learn more about protecting groundwater in your area? Get in touch with our environmental specialists. We offer free consultations to discuss your local water quality concerns.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.