What is Treatment of Boiler Water in Water Softening?

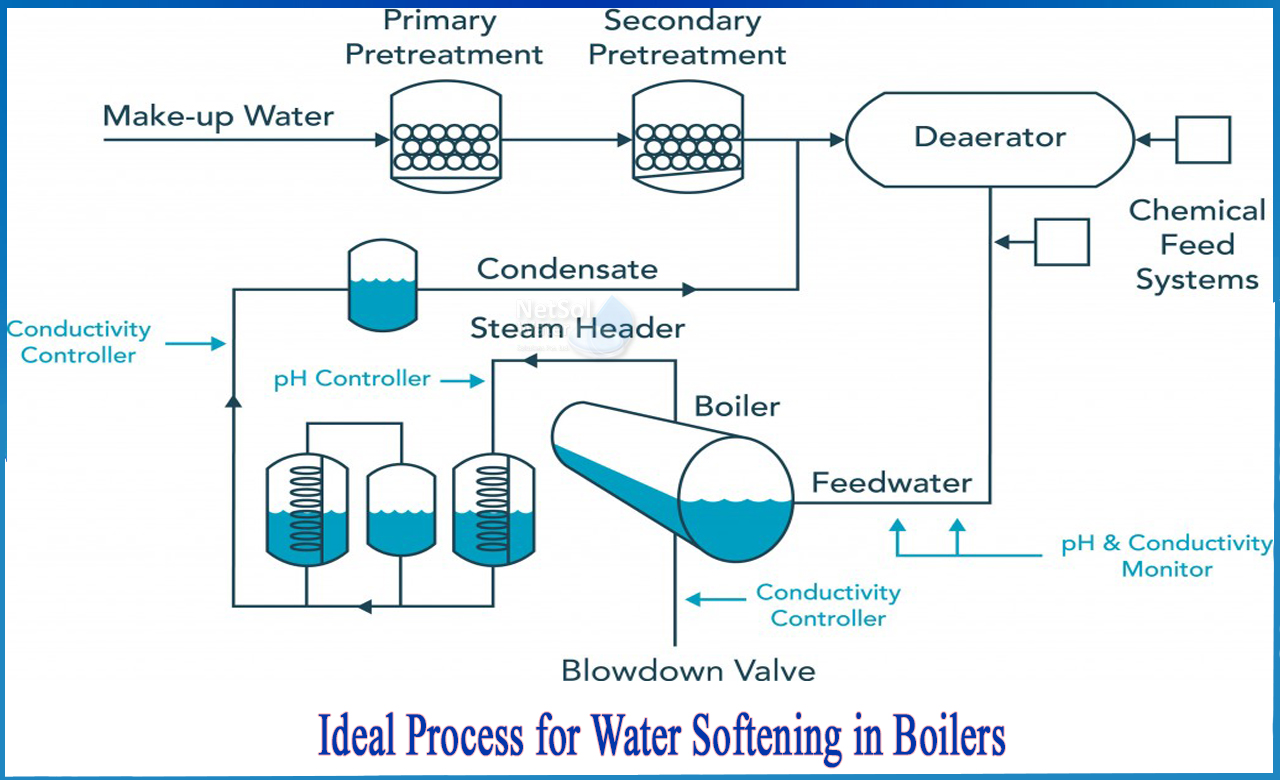

The term "pre-treatment" (external treatment) refers to the treatment of the raw or mains water supply up to the hot well/deaerator. The following steps cover the treatment that occurs between the feed tank and the boiler itself.

>When agitated, the water should be clear and produce no stable foam.

>The pH should be between 8.5 and 9.5 (9.2 in systems containing copper alloys)

>There should be no hardness, oil, or grease in the water.

FILTRATION

When water is drawn from a non-potable source, it may be necessary to filter the water to remove solid matter. Depending on the source, a variety of techniques can be used:

· Sedimentation (allowing time for heavier particles to sink naturally)

· Clarification (using charged particles to attract fine suspended solids into clumps that can then be clarified sinking after that)

· Filtration with sand/carbon

WATER SOFTENING

When it comes to industrial boilers, all mains water is hard water (even if you live in an area that the washing powder companies consider to have soft water!).

The amount of hardness salts must be reduced to less than two parts per million (calcium carbonate). If this level is not maintained, a hard 'rock-like' substance (scale) forms on the heat transfer surfaces of the boiler, forming an insulating layer that reduces boiler efficiency and raises metal temperatures. Some of the solid material will break off and settle in the boiler's bottom. Insulated surfaces, if left unchecked, can overheat and crack, resulting in leaks or even catastrophic failure.

THE CHEMICAL PROCESS - ION EXCHANGE

Magnesium, calcium, and iron are all positively charged ions found in hard water. The use of resin beads in an ion exchange in a water softener removes positively charged ions from the water. Brine, which contains salt and potassium, negatively charges the resin beads inside the resin tank. As the water flows through the resin tank, the magnesium, calcium, and iron are chemically attracted to the negative charge of the resin beads and adhere to the resin. The majority of the "hard" minerals are removed from the water during this process, resulting in "soft" water.

THE CLEANING PROCESS - REGENERATION

Regeneration cycles are required to clean the resin beads, allowing the system to remove hardness from the water supply on an ongoing basis. The regeneration process consists of flushing out the solids, drawing brine from the brine tank, and recharging the resin beads, which can take up to two hours. If your softener has only one resin tank, hard water will be supplied to the boiler during the regeneration process. In a two-tank system, the standby resin tank will activate during the regeneration of the first tank to maintain the flow of soft water to the boiler.

The Bottom Line – Access to Soft Water

To avoid damage and costly repairs, it is critical to keep your boiler supplied with soft water at all times. When combined with a dependable water treatment chemical programme and blowdown schedule, water softening can provide many years of dependable boiler system performance.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.