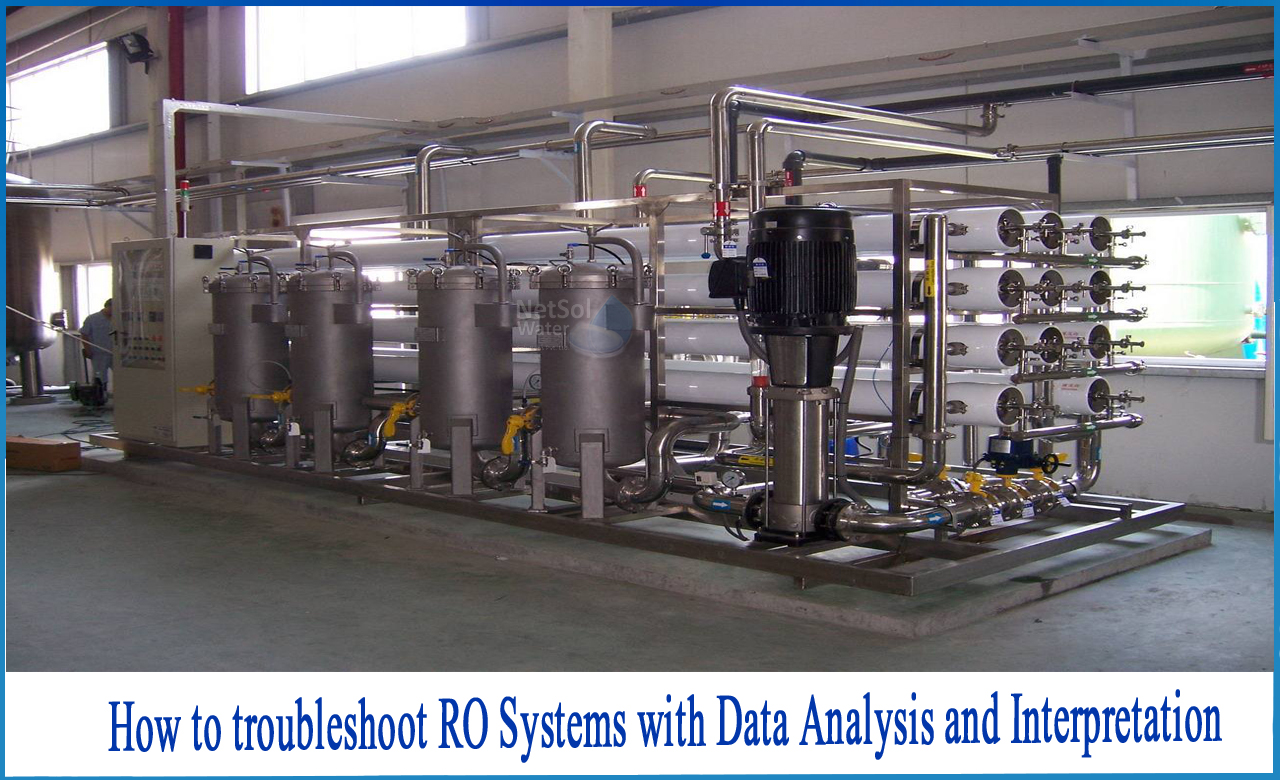

How to troubleshoot RO Systems with Data Analysis and Interpretation?

RO operator is worried with two things: the quality and the amount of water generated. A variety of variables can influence these two elements, including feed water pressure, system recovery, and changes in feed water quality, to name a few.

Troubleshooting potential RO system problems

You can proactively address any problems before irreversible damage to the RO membranes occur, by collecting operating data, normalizing the data, and then trending the normalised data over time and comparing the values to a baseline (a baseline is considered the start-up values when the RO membranes are new or after they have been cleaned or replaced).

There are three determined variables that can help troubleshoot potential RO system problems concerning the quantity and quality of water produced by the RO system and provide a better picture of genuine membrane function.

Normalized Permeate Flow or (NPF), Normalized Salt Rejection or (NSR), and Normalized Pressure Differential or (NPD) are the three determined parameters to track and trend problems in RO Systems.

1: Normalized Permeate Flow or NPF:The amount of permeate water produced by the RO is measured by the NPF. If the NPF dips 10% to 15% below the baseline value, fouling or scaling of the RO membranes has occurred, and the RO membranes should be cleaned.

If the NPF rises, it indicates that the RO membrane has been damaged. Chemical attack (from an oxidizer like chlorine) or a mechanical issue (such as an O-ring failure) on the membrane might cause this damage.

2: Normalized Salt Rejection or NSR:Itmeasures how successfully the RO membrane rejects salts (contaminants) and is hence connected to the quality of the permeate water. When the NSR falls, the amount of salts passing through the RO membrane rises (lower quality permeate). Fouling, scaling, or degradation of the RO membranes might cause a drop in NSR.

A good RO membrane should have a rejection rate of 97 to 99 percent, while a membrane is called 'poor' if the rejection rate lowers to 90 percent or less. During typical operation of a RO membrane, you should expect the NSR to steadily decrease over time.

RO membranes typically last several years before needing to be replaced, and a continuous drop in NSR is a common symptom of aged membranes. The NSR can be improved by following a thorough cleaning schedule for RO membranes.

NSR can aid in the detection of biofouling problems!

When biofouling is a concern, the NSR will frequently increase while the NPF decreases. This is due to the biofoulant's ability to plug microscopic flaws in the RO membrane, hence boosting salt rejection. Many substances such as CO2, methane, and organic acids begin to seep through the membrane when the biofoulant layer ages and dies, compromising the quality of the permeate water.

3: Pressure Differential or NPD:The NPD indicates the cleanliness of the feed water spacer on the membrane. Because these spacers are only a few tenths of an inch thick, they are particularly prone to plugging. As a result of the blockage, the resistance to flow increases, as does the pressure drop.

Due to fouling or scaling, the NPD will begin to rise over time, and RO membranes should be cleaned when it rises 15% to 25% above the baseline value. To identify when the RO membranes should be cleaned, NPD and NPF should be monitored concurrently. The NPF will frequently decline while the NPD will remain stable.This is due to the fact that the feed water spacers have yet to be plugged by fouling/scaling concerns. With time, the NPD will rise in tandem with the decrease in NPF.

A drop in NPD is mainly caused by defective instrumentation or data gathering errors.If the NPD for each stage of a RO can be measured, fouling and scaling problems can typically be distinguished based on the location of the increased pressure drop. Increases in NPD in the first stage of RO indicate fouling concerns, while increase in the second stage imply scaling.

How can we help?

Netsol Water will design and choose the membrane that best suits the needs of your business and the project. We integrate RO technology with the appropriate pre-treatment and post-treatment to deliver long-term and full solutions.

Our water and wastewater treatment systems provide the following benefits_

1: Engineered and custom-designed solutions for one-of-a-kind requirements.

2: Design, engineering, manufacture, automation, installation, maintenance, and training are all included in turnkey systems.

3: Water and wastewater treatment, recycling, reuse, and disposal using cutting-edge technologies.

4: On-line assistance and on-site service and support are at our best.

For further assistance or product-purchase-related queries, call us at +91-9650608473 or email at enquiry@netsolwater.com.