How to treat tailings in mining operations?

Strict laws governing the wastewater produced by mining activities, as well as the need to avoid disposing of liquid waste that might harm the environment, are becoming increasingly important.

If the industries do not take the appropriate steps to treat the wastewater they create, these requirements may have a significant impact on their enterprises' profitability. One of the most difficult issues a mining business confronts in keeping its operating license is determining the most appropriate and long-term wastewater treatment.

Wastewater in mining

Depending on whether the mine is underground or open pit, whether it has a positive or negative water balance, and the refining process, wastewater can be created in a variety of ways in a mining operation.

The following elements are commonly found in mine-water:

1: Free Acid

2: Sulfate and carbonate

3: Metals such as iron (Fe), aluminium (Al), calcium (Ca), magnesium (Mg), manganese (Mn), and sodium (Na)

4: Particles in suspension

5: Products containing chemicals

What are Mine-Tailings?

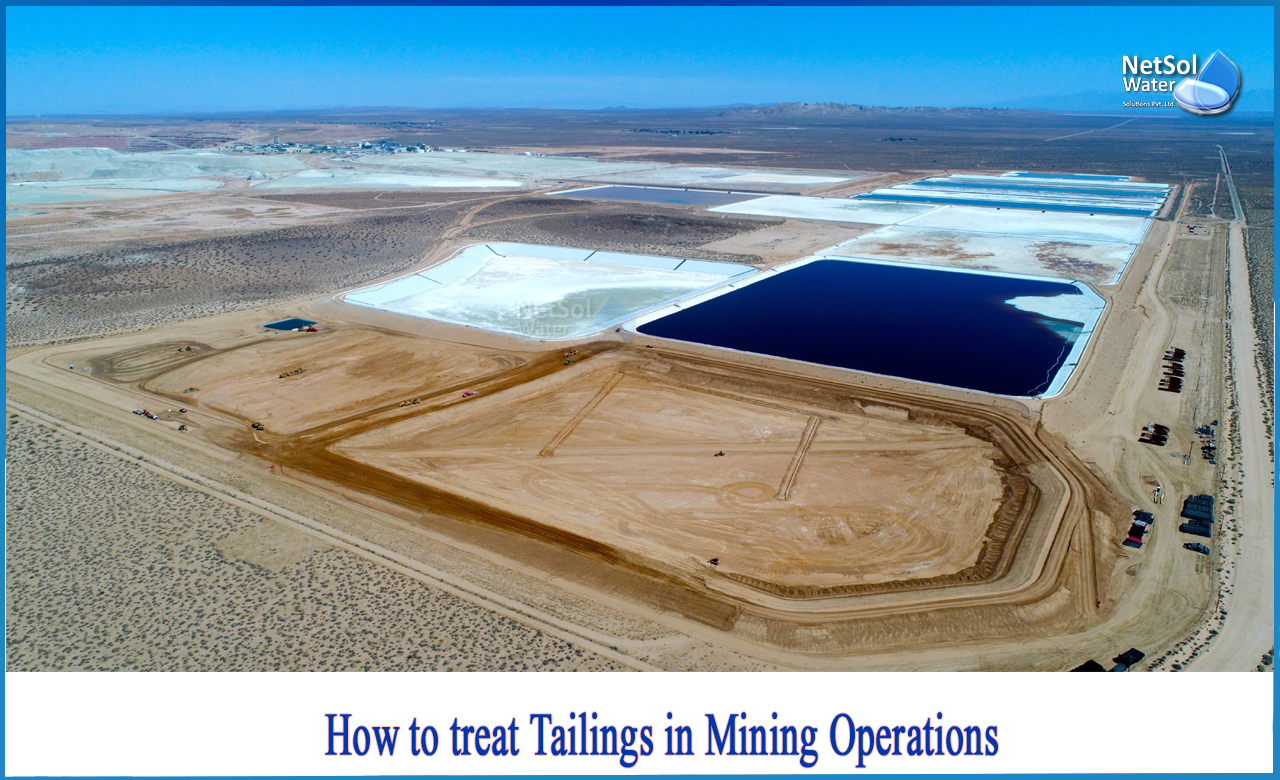

Tailingsrefer to the wastewater produced by the mining sector, waste from extraction operations, equipment cleaning water, and the refining process.

It's a sludge-like waste made up of fine gangue particles, chemicals, and water that's held in enormous structures called tailings dams or ponds in many circumstances. Tailings are a key environmental obligation for a mining operation since they cover huge amounts of land and include metal-contaminated water that must be handled either during operation or after the mine shuts.

Issues with Wastewater Mining

While important for mineral processing, the basic principles of mining wastewater treatment dealing with water that comes into contact with ore and other impurities cause rock fragments to leach into the process water. As the water gets contaminated with more metals and sulphates, the acidity of the water will grow.

Mining-influenced water (MIW) is created as a result of this process and is defined as any water that has been chemically altered by mining or mineral processing. The following are the most serious problems associated with water contaminated by mining:

1: Mine drainage is acidic.

2: Pollution caused by chemical processing.

3: Contamination and leaching of heavy metals.

4: Erosion and sedimentation.

Any of these issues might lead your water to fail to meet regulatory requirements, requiring you to treat it or properly dispose of wastewater.

Treatment for Mining wastewater

When it comes to mining water treatment, the focus is on treating process water. Water linked with mine drainage and stormwater, on the other hand, must be treated if water efficiency is to be maximized.

The major aims, regardless of whatever water source you're treating, are to remove metals, sediments, and other impurities from the water while also restoring the pH levels to ideal levels. Chemicals and mechanical filtering must be used to treat your mining effluent.

1: pH Reducing Agents

When treating mining wastewater, one of the first steps is to return the water's pH to its original level. This is vital not only for maintaining the quality of your water, but it will also aid in the precipitation of dissolved metals. Positively charged metal ions react with negatively charged hydroxide ions when the pH of the water is raised. This produces a metal particle that is dense and insoluble, making it simpler to deal with.

pH adjusters, when used correctly, can assist to reduce the acidity of your mining wastewater and return it to a more balanced pH level. While a pH of 7 is considered neutral, it is recommended that your mining water be restored to a pH of 8 or above.

2: Flocculants and Coagulants

You may use coagulants and flocculants to mix the tiny metal particles and suspended solids in your water into bigger clumps after adjusting the pH levels. This makes mechanically filtering and removing them easy.

3: Chemicals

While pH adjusters, coagulants, and flocculants are the most often used chemicals in mining wastewater treatment, specific applications necessitate the use of additional chemicals to safeguard your systems or to prepare your water for filtering. These can include the following:

-Ion exchangers and water softeners

-Corrosion Inhibitors

-Algaecides and biocides

4:Filtration

Mechanical filtering methods can eliminate any suspended particles and some forms of organic matter after you've maximized the quality of your water with the correct chemicals. While there are a variety of devices to choose from, the following are the most common types of mechanical filtering equipment:

-Centrifuges

-Filter Presses

-Belt Presses

What are some other treatment options for Mining Industry Wastewater?

Because mining wastewater is so diverse, there are a variety of treatment options including mechanical filtering technologies. While some equipment is superior to others in the majority of circumstances, each solution has its place in the correct application.

Biological Processes, Desalination, Clarification, Evaporation & Crystallization, Disinfection, Filtration, Ion Exchange, Membrane Separation, Package Plants, Sludge Dewatering & Handling, and Zero Liquid Discharge are all examples of wastewater treatment technologies.

Choose the best water treatment experts!

Contact Netsol Water team now to learn more about how we can assist with your mining wastewater treatment or to discuss your specific requirements. Make an appointment for your free consultation now via phone at +919650608473 or contact via email at enquiry@netsolwater.com for a consultation on which methods of water treatment might be most effective for you.