Membrane filtration is a pressure-driven, physical separation procedure that divides molecules of various sizes and characteristics, using a membrane system. A single feed stream is passed through a membrane during membrane filtration, which creates a physical barrier that only allows specific molecules with particular properties to pass through.

The membrane's size and filtering medium determine the stuff that goes through it. Microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO), are the four most popular forms of membrane filtration.

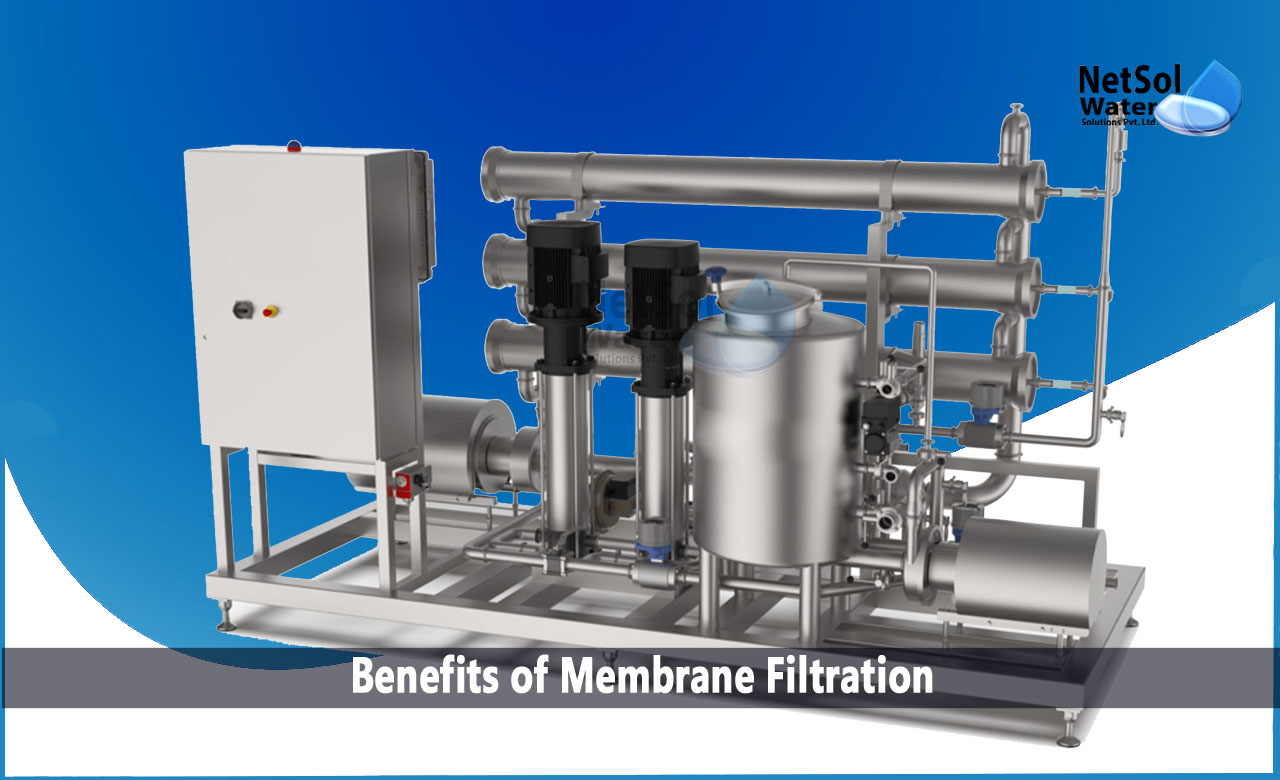

What are the benefits of Membrane Filtration?

The main advantages of membrane filtration systems for various processes are discussed here.

· High adaptability

Membrane filtration has a variety of uses, including the removal of dissolved chemicals and large particle matter. This means that a variety of membrane filtering devices is available to meet your demands, regardless of your separation challenges or application requirements.

· Reduced manufacturing costs

Membrane filtration is typically less expensive than alternative methods. Its reduced installation costs, lower energy expenses, and fewer processing stages are the reasons behind this. At the same time, it generates higher overall yields and purity levels. Membrane filters don't produce a filter cake, which practically eliminates disposal costs.

· Chemical-free

Membrane filtration is the best option to decrease chemical concentrations used in water treatment, because it doesn't call for any chemical additives. Instead of adding chemicals, like those used in chlorination, membrane filtering actually removes microorganisms.

· Pathogens are eliminated

Almost, 90% of pathogens in the process fluid can be removed by membrane filtering.

· Efficacy in using energy

Membrane filtration uses a tiny amount of energy. For instance, 20% less energy is used when ultrafiltration is used before nanofiltration and reverse osmosis.

· Preserves protein integrity

One of the best techniques for isolating proteins without denaturing them is membrane filtration. It maintains the integrity of proteins because it doesn't add heat or chemical reagents.

· Perfect for testing

Fluid sample analysis for different types of contamination can be done successfully using membrane filtration. It can isolate and count different bacterial colonies by moving the membrane filter, from one medium to another.

· Time is saved

Membrane filtration yields quantitative data more quickly than the MPN (most probable number) approach. Results from membrane filtration can be seen after just 24 hours.

· Superior final product

Membrane filtration is a safe, environmentally friendly technology that provides accurate, timely results. The separation procedure does not require additives because it simply considers molecule size. This leads to a high-quality final product that more readily, meets the demands of customers and regulatory authorities.

Membrane filtration systems from experts in Water Treatment

Membrane filtration is utilized in a variety of processes, including the processing of dairy products, wastewater treatment, beer brewing, etc. Numerous advantages of the separation process include flexibility, fewer energy needs, cheaper production costs, the capacity to sterilise heat-sensitive materials, and the elimination of up to 100% of microorganisms.

Netsol Water offers specialised membrane filtration systems, like RO Plants to satisfy the specific needs of your particular applications. To begin developing your unique solution right now, get in touch with us or submit a price request. For further information or to make a product purchase, contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com