How to Reduce Sludge Production in STP Plant?

Every STP plant facility creates sludge as a waste material that results from wastewater treatment procedures. The excessive production of sludge causes financial burden for disposal procedures while creating environmental concerns alongside losses relating to treatment chemicals. Sewage Treatment Plant efficiency improvements along with decreased treatment expenses result from lowering sludge quantities.

Factors Contributing to Sludge Production in an STP

· Composition of Wastewater: Wastewater composition controls the amount and nature of sludge produced by STPs.

· Treatment Process: Different solution configurations within STPs including activated sludge along with sequencing batch reactors and membrane bioreactors produce dissimilar sludge outputs.

· Operational Parameters: Multiple conditions like aeration rate along with sludge retention time and microbial activity determine the amount of sludge produced during treatment.

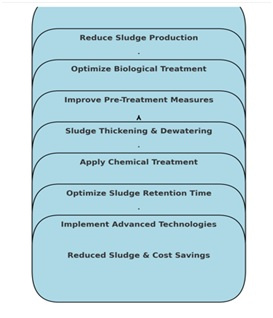

Effective Strategies to Reduce Sludge Production

Optimize Biological Treatment

· A combination of appropriate ventilation with suitable sludge duration enables microbial decomposition of all organic substances in the water system.

· Utilize sophisticated biological treatment like anaerobic digestion to reduce the sludge volume.

Intensify Pre-Treatment Measures

· Remove large solid masses and grease as pre-treatment to minimize the burden of the units in secondary treatments.

· Use the fine screening and grit removal system to minimize undesirable accumulation of solid material.

Sludge Thickening and Dewatering Technologies

· Using gravity thickeners or centrifuges in conjunction with other efficient sludge thickening units will decrease sludge moisture content.

· Screw presses or belt filter systems enable sludge volume reduction before disposal.

Apply Chemical Treatment

· Chemical solutions together with coagulants and flocculants help sludge solidify during settling procedures and prevent excessive biomass build-up.

· The sludge destruction process can be accelerated through bioaugmentation using enzymes in treatment systems.

Control Sludge Age in Biological Treatment Processes

· Prevent excessive levels of sludge in biological reactors with the right mix of sludge age.

· This helps prevent generating too much unnecessary biomass

Adopt Sludge Reduction Technologies

· Research innovative methods to decrease sludge amounts including thermal hydrolysis systems together with ozonation methods or ultrasonic processing approaches.

· Membrane bioreactor systems combine with digestion processes for reducing sludge production rates.

Advantages of Sludge Reduction in STP Plant

· Low Operation Cost: With reduced sludge volume, most costs associated with transportation, handling, and disposal are decreased.

· Environmentally Friendly: Reducing sludge production lowers landfill dependency and the emission of greenhouse gases.

· Better Treatment Efficiency: Proper management of sludge can better upgrade plant performance and influence effluent quality.

· Regulatory Compliance: Sludge reduction efficiency enables facilities to maintain full compliance with environmental standards as well as wastewater release parameters.

Conclusion

Sewage Treatment Plants (STP) need systematic process optimization along with innovative treatment solutions and operational methods to minimize sludge amounts. Sludge management techniques implemented by industrial facilities and municipal bodies create both efficient wastewater treatment processes and solid regulatory compliance and financial sustainability.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com