How to maintain clarifiers?

Clarifiers are costly to purchase and maintain, and their downtime can result in fines from regulatory bodies as well as community ill will. Regular maintenance, an annual inspection of the mechanism, and a touch-up of the paint or coating system on occasion are all simple and inexpensive proactive measures.

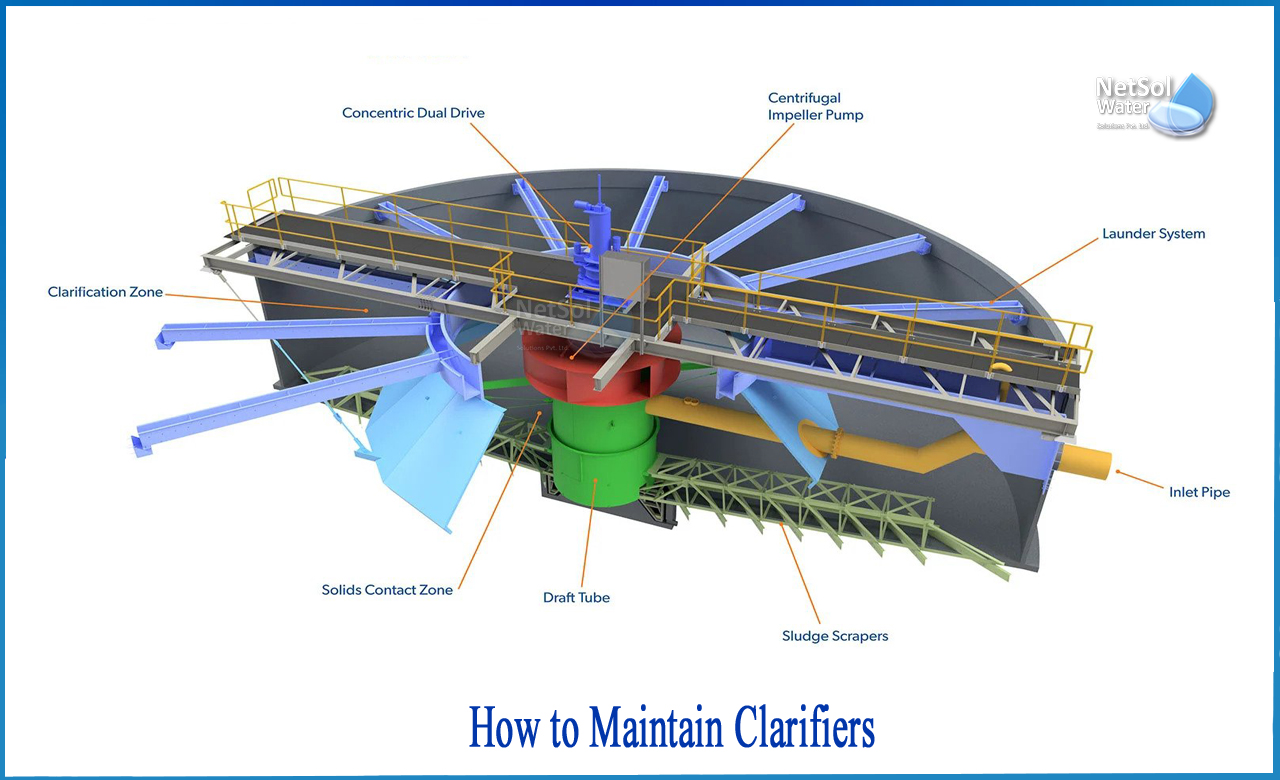

The effluent system, sludge removal system, and drive are three components of all clarifiers that require maintenance. The effluent and sludge removal systems only need to be serviced once in a while;however, the drive needs to be serviced on a regular basis.

Maintenance of a System of an Effluent

A V-notched weir connected to a launder is the most common effluent system. The weir and launder must be kept clean and clear of algae, and the weir must be kept level. This can be accomplished by cleaning with brushes and even chlorine. To make cleaning easier, some operators paint the launders with epoxy paint.

Spring-loaded brushes attached to the rotating mechanism clean the weir, laundry walls, and scum baffle in one cleaning system. Installing opaque laundry covers to block the admission of growth-promoting light is an efficient way to avoid algae growth.

Maintenance of the Sludge Removal System

Squeegees sweep the tank floor in most sludge removal systems. It is critical that they sweep the floor thoroughly. As a result, whenever the tank is drained, they should be inspected and adjusted. Seals are installed at all revolving and stationary places in suction clarifiers. When influent is sucked straight into the underflow due to leaking seals, "short-circuiting" occurs. This can be avoided by replacing worn seals as soon as possible.

If the flow rate is too low, riser pipe valves can block. Foreign debris can also clog orifices in suction headers. As a result, the tank should be cleaned on a regular basis. To remove dead leaves, some operators plan tank cleaning in autumn.

Maintenance of the Clarifier Drive

Six factors must be considered when maintaining a clarifier:

Removal of condensate: Water condenses and gathers in all clarifier drives, causing the main gear and bearing to corrode and fail soon if left unattended. As a result, the removal of this water on a regular basis is the single most important part of drive maintenance. Condensate is evacuated using cock-type valves on clarifier drives. The condensate should be drained at least once a week, and more frequently in locations with considerable rainfall or humidity. The operator should keep track of how quickly condensate builds up in each drive and remove it as needed.

Lubrication: Lubrication is required for the primary and secondary reducers, as well as the main gear and bearing. Wherever possible, the operator should grease the reducers, check all oil levels weekly, and drain and change the main gear oil every six months. The main bearing and gear in a growing number of drives are grease-lubricated rather than oil-lubricated, and condensate drains continuously from the drive casing through small "weep" holes.

Torque control is working properly: An occasional check to ensure that the torque control is working properly can save the drive and clarifier from severe harm.

While the drive is running, the operator should work the bypass over the range of the visual indicator. The torque control mechanism should be fixed as soon as the torque alarm or the motor cutout fails to operate at the specified torque levels.

Reducer bearings and seals need to be maintained and/or replaced: Bearings and seals in all types of primary and secondary reducers must be greased and replaced as needed. Seals and bearings must be replaced according to the manufacturer's specifications as they wear out. Oil or grease will seep from worn seals. Bearings that are worn will produce a noise or become hot. They should be replaced before the rest of the drive system is harmed.

Upkeep of the chain: The drive chain should be lubricated. Because they penetrate and lubricate chain pins and rollers without producing excessive accumulation, these lubricants are suitable. With a straightedge, the operator should verify the alignment of the sprockets and adjust the drive chain so that there is no excessive slack.

Monitoring the wear of the strip liners: Strip liners have a 10- to 20-year lifespan. If properly maintained, the precision main bearings utilised by some manufacturers will easily outlast the remainder of the clarifier system. Excessive noise or a noticeable drop in the top of the drive, which could cause the scrapers to drag on the clarifier floor, are both signs that the strip liners need to be replaced.

Several companies that design and manufacture equipment’s also provide cleaning and maintenance services. Netsol's team of clients and other professionals has seen the benefits first hand.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.