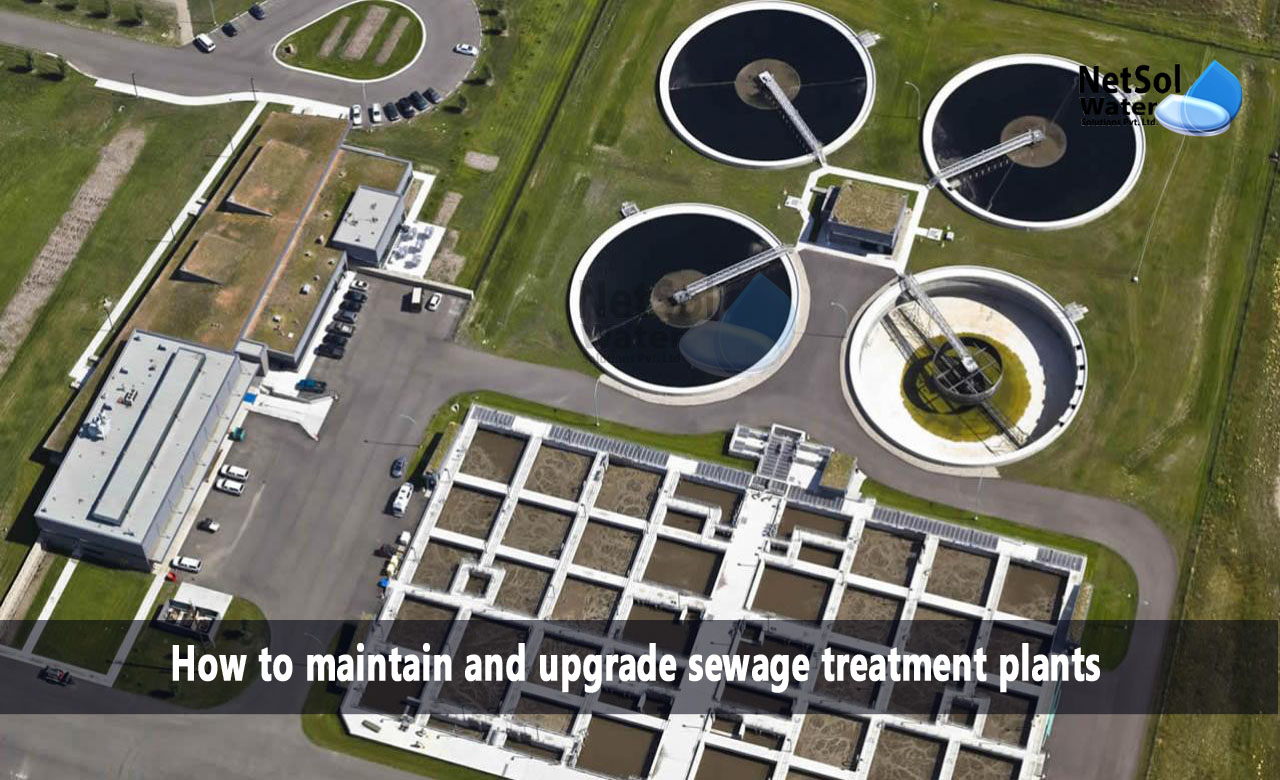

How to maintain and upgrade sewage treatment plants?

Sewage treatment plants are crucial infrastructure that ensures the safe and effective management of wastewater. To maintain optimal performance and keep up with evolving regulations and technological advancements, regular maintenance and periodic upgrades are essential.

In this blog post, we will explore the best practices for maintaining and upgrading sewage treatment plants, as well as the challenges that plant operators face in this process.

Importance of Maintenance

Regular maintenance is vital for the smooth operation of sewage treatment plants. It helps prevent equipment failures, ensures efficient treatment processes, and minimizes the risk of environmental pollution. Some key maintenance practices for sewage treatment plants include:

- Routine Inspections: Regular visual inspections, equipment checks, and process monitoring help identify potential issues before they escalate into major problems. This includes inspecting pumps, blowers, motors, valves, and instrumentation systems.

- Preventive Maintenance: Implementing preventive maintenance schedules and procedures helps extend the lifespan of equipment and reduces the likelihood of unexpected breakdowns. This includes tasks such as lubrication, calibration, cleaning, and replacing worn-out parts.

- Cleaning and Debris Removal: Sediment and debris accumulation in tanks, channels, and pipes can impede the flow of wastewater and affect treatment efficiency. Regular cleaning and removal of debris are necessary to maintain optimal plant performance.

- Performance Monitoring: Continuously monitoring and analyzing key performance indicators (KPIs) such as effluent quality, energy consumption, and sludge production enables plant operators to identify areas that require improvement and implement corrective measures.

Challenges in Maintenance and Upgrades

Maintaining and upgrading sewage treatment plants come with a unique set of challenges that plant operators must navigate. Some common challenges include:

- Aging Infrastructure: Many sewage treatment plants face the challenge of aging infrastructure, including outdated equipment and systems. Upgrading these plants requires careful planning, budgeting, and phasing to minimize disruptions to the treatment process.

- Regulatory Compliance: Evolving environmental regulations and discharge standards pose challenges for plant operators. Keeping up with regulatory requirements and implementing necessary upgrades to meet these standards can be complex and resource-intensive.

- Financial Constraints: Adequate funding for maintenance and upgrades is crucial but often limited. Securing sufficient financial resources can be challenging, especially for smaller plants or those serving economically disadvantaged communities.

- Technological Advancements: Embracing new technologies and upgrading treatment processes can improve efficiency and environmental performance. However, integrating new technologies requires careful consideration, training, and expertise to ensure successful implementation.

Best Practices for Upgrades

When planning upgrades for sewage treatment plants, the following best practices should be considered:

- Comprehensive Assessment: Conduct a thorough assessment of the plant's current state, including infrastructure, equipment, and processes. This assessment will help identify areas that require upgrades or improvements.

- Prioritization and Planning: Prioritize upgrades based on critical needs, regulatory compliance, and long-term goals. Develop a comprehensive plan that outlines the sequence, timeline, and budget for the upgrades.

- Engage Stakeholders: Involve plant staff, engineers, regulators, and other stakeholders in the upgrade process. Collaboration and open communication will help ensure that upgrades align with operational needs and regulatory requirements.

- Pilot Studies and Testing: Before implementing major upgrades, consider conducting pilot studies or trials to evaluate the effectiveness and feasibility of new technologies or processes. This will help mitigate risks and inform decision-making.

- Training and Knowledge Transfer: Upgrades often involve new technologies or processes. Provide adequate training to plant operators and staff to ensure a smooth transition and maximize the benefits of the upgrades.

Conclusion

Maintaining and upgrading sewage treatment plants is essential to ensure their continued efficiency, regulatory compliance, and environmental performance. Regular maintenance practices, including inspections, preventive maintenance, and performance monitoring, help identify and address issues proactively. Overcoming challenges related to aging infrastructure, regulatory compliance, financial constraints, and technological advancements requires careful planning, stakeholder engagement, and prioritization. By implementing best practices and embracing upgrades, sewage treatment plants can continue to play a crucial role in safeguarding public health and the environment.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.