How Thermal Hydrolysis Works and Its Benefits?

Wastewater treatment plants produce large volumes of sewage sludge as a byproduct of the wastewater treatment process. This sludge contains valuable nutrients and energy that can be recovered through anaerobic digestion, where microorganisms break down organic matter in the absence of oxygen to produce biogas. However, the digestibility of sewage sludge is often limited by its complex composition and structure. Thermal hydrolysis is an advanced sludge pretreatment process that uses steam and high pressure to break down the cellular structure of sludge, making it more accessible to anaerobic microorganisms and enhancing biogas production.

Thermal hydrolysis involves subjecting sludge to high temperature (160-180°C) and pressure (4-6 bar) for a short time period (15-60 minutes). This causes the sludge cells to rupture, releasing soluble organic matter from inside the cells. The process essentially “cooks” the sludge, hydrolyzing proteins, fats and carbohydrates into smaller molecules. This makes the sludge more readily digestible for anaerobic microbes, allowing faster and more complete digestion. Thermal hydrolysis of sludge prior to anaerobic digestion can increase biogas yields by up to 50%.

How Thermal Hydrolysis Works?

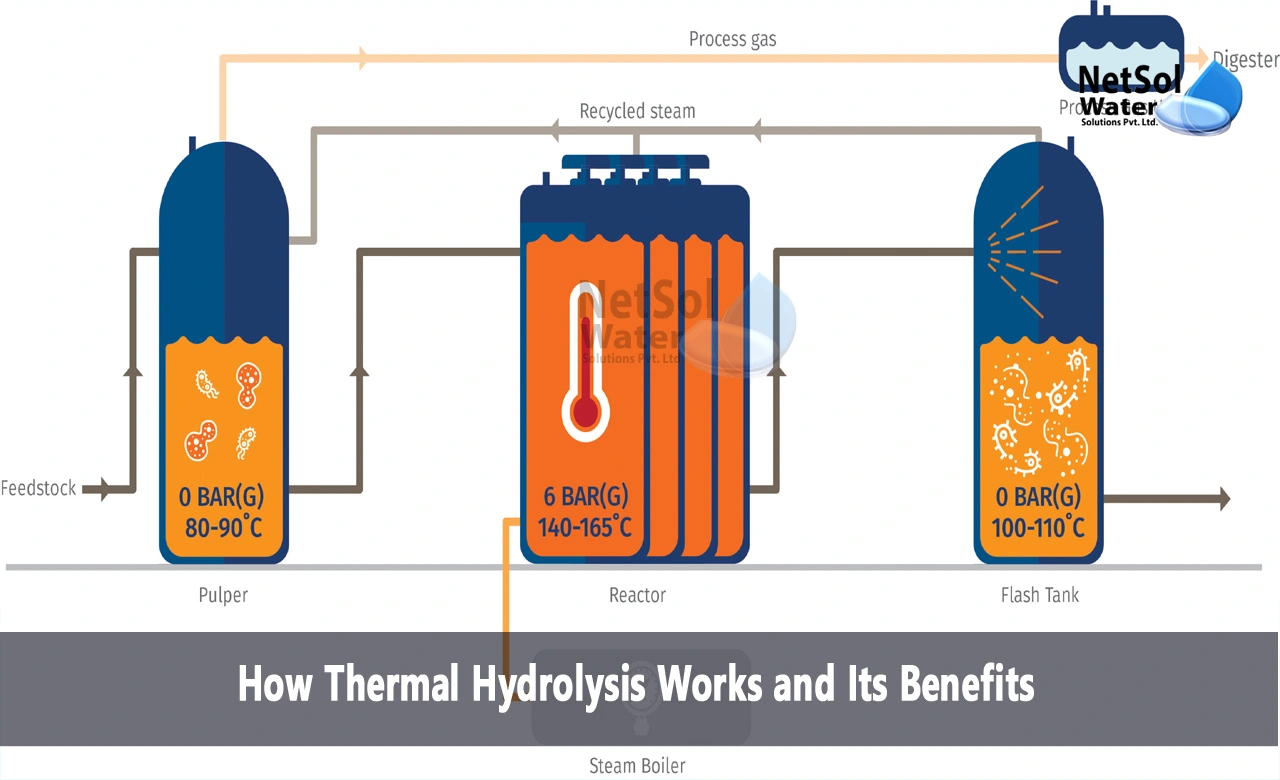

The thermal hydrolysis process consists of several key steps. First, sludge is pumped into a hydrolysis reactor where it is heated to 160-180°C using direct steam injection. The reactor is pressurized to 4-6 bar to prevent boiling. To achieve uniform heating, the contents of the reactor are thoroughly mixed. Heating under high pressure causes the water in the sludge to reach liquid phase despite the high temperature. This allows efficient heat transfer into the sludge particles.

The high temperature and pressure cause the cellular membranes in the sludge to rupture. This bursts the cells open, releasing organic compounds and nutrients from inside. High heat also breaks apart large organic molecules like proteins and carbohydrates into smaller, more soluble fragments through hydrolysis reactions.

After the designated reaction time (15-60 mins), the pressure in the reactor is rapidly reduced, causing the treated sludge to explosively decompress. This violent decompression creates additional shearing forces that further break apart sludge flocs and cells. The end result is a sludge with dramatically increased soluble organic content and decreased particle size.

The treated sludge is then sent to anaerobic digesters, where microorganisms can rapidly consume and digest the increased availability of soluble organics, accelerating biogas production. Some thermal hydrolysis processes recycle heat from the process to preheat incoming sludge and optimize energy efficiency.

Benefits of Thermal Hydrolysis

Thermal hydrolysis offers several important benefits for wastewater treatment plants:

1- Increased biogas production: By rupturing cells and solubilizing organics, thermal hydrolysis provides anaerobic microbes with readily accessible food for faster digestion. Biogas yields can be increased by 20-50%.

2- Improved dewaterability: Thermal hydrolysis breaks down Extracellular Polymeric Substances (EPS) that bind water to sludge flocs. This improves sludge dewatering, reducing volumes for disposal.

3- pathogen reduction: The high temperatures kill pathogens and reduce biosolids volumes for safe agricultural reuse. Over 95% of indicator organisms are inactivated.

4- Lower polymer demand: With EPS breakdown and smaller floc size, less polymer is needed for conditioning prior to dewatering. Total polymer dose can be reduced by up to 40%.

5- Increased organic removal: More complete digestion means less organics leave in residual biosolids. This improves final effluent quality.

6- Smaller digesters: Increased biogas rates allow equivalent digestion in smaller reactors, reducing capital costs. Existing digesters can handle higher sludge loads.

7- Increased digester capacity: More sludge can be treated and digested in the same digesters when hydrolysis is added. This accommodates growing sludge volumes at many plants.

8- Co-digestion benefits: Thermal hydrolysis improves digestion of low-biodegradability co-digestion feeds like food waste.

Overall, thermal hydrolysis enhances anaerobic digestion performance, economics, and environmental sustainability of sewage sludge management.

Conclusion

Thermal hydrolysis is an increasingly popular technology to enhance sewage sludge anaerobic digestion. By applying heat and pressure, it ruptures microbial cells to solubilize organic matter and make sludge more digestible. This significantly increases biogas yields, improves dewatering, reduces pathogen levels, and provides other benefits like increased digester capacity. However, it also adds complexity and costs that must be evaluated.

Overall, thermal hydrolysis represents a major advance in sludge pretreatment for plants seeking to maximize resource recovery from wastewater solids. The technology can transform sludge from a difficult waste disposal headache into a valuable source of renewable energy and fertilizer. However, it requires thorough assessment of local needs and conditions to determine if benefits outweigh required investments and operational changes.

When implemented strategically, thermal hydrolysis of sewage sludge enables wastewater plants to improve sustainability and value recovery from the massive organic wastes they handle daily. They can reduce their environmental footprints and convert sludge into renewable energy to offset plant energy demands. With skilled engineering and operation, thermal hydrolysis can turn sludge into an asset rather than just a cost. As wastewater plants strive to improve their environmental performance, such sludge-to-energy solutions will grow in popularity and application worldwide.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com