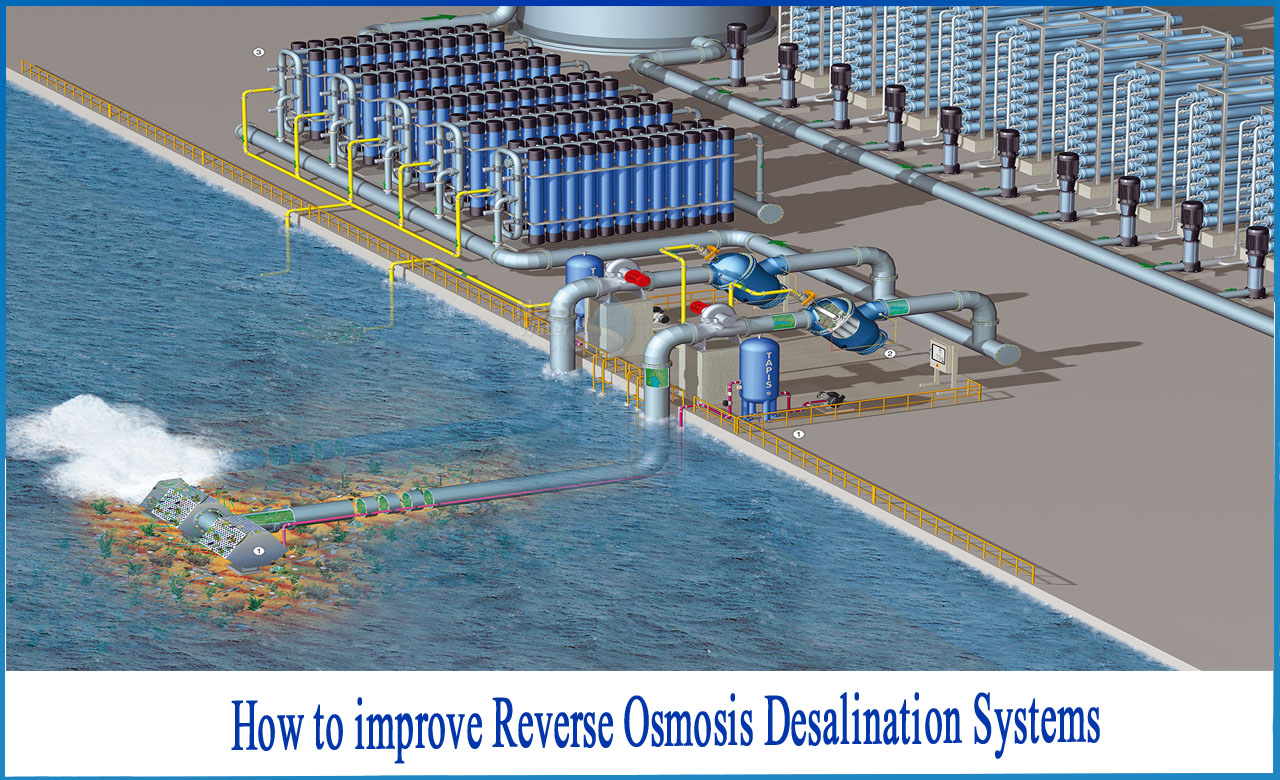

How to improve Reverse Osmosis Desalination systems?

The Industrial RO (Reverse Osmosis) plant is an advanced technique that has proven to be a benefit for industrialists, restaurants, housing societies, and hospitals by supplying clean and filtered water for both production and consumption. They are highly recommended since they effectively remove up to 99 percent of dissolved sediments, pollutants, and impurities from water, ensuring that it is pure, safe, and clean.

A number of pre-treatment processes, such as softening, de-chlorination, and antiscalant treatment, are required for the Industrial RO Water Plant. Following the pre-treatment procedure, high pressure is utilized to force water through a semi-permeable membrane, which traps all impurities while allowing clean water to flow through. Energy levels are determined by the quantity of salts and pollutants in the water. To filter 1 cubic metre of water, an industrial Reverse Osmosis system uses 6 kilowatt-hours of power on average

Let us look at some ways to improve RO Desalination Systems

1. Back pressure method for balancing the system's water flux distribution

Reverse osmosis is a pressure gradient-driven membrane separation method. The water flux of the membrane is increased as the feed water pressure is increased, but the salt permeation is unaffected. Increased water flux will lower the salt level in the product water in the case of constant salt penetration.

The pure driving pressure of the system will create a significant gradient under the same water flow, that is, the pure driving pressure at the inlet end will be extremely high, and the pure driving pressure at the concentrated water end will be very low. This is due to the friction loss of the membrane element, which causes concentrated water permeation to be higher than concentrated water pressure. As a result, the front-end membrane element will create a large volume of fresh water with a high salt concentration, whereas the end membrane element will produce less amount of fresh water with a low salt content. The concentration polarisation of the front-end membrane element will be severe under these conditions, affecting the salt content of the product water and perhaps speeding up the membrane fouling rate.

2. Remove free CO2 from RO supply water by adjusting the pH value

Due to the features of the membrane element, the penetration rate of dissolved gases in water, such as CO2, is about 100 percent, whereas the permeation rate of HCO3- falls as the pH value rises.

Bicarbonate in water is unstable. It can exist in three forms: HCO3-, CO32-, and CO2+H2CO3. When the pH is around 8.3, the solution is virtually entirely made up of HCO3-. In light of the foregoing, in addition to providing NaHSO3 reduction agent and a scale inhibitor before the RO membrane security filter, add NaOH to bring the pH of the reverse osmosis input water to 8.2-8.3, allowing reverse osmosis to remove the greatest amount of free CO2.

Increase the fixed yield of the mixed bed by increasing the reverse osmosis desalination rate to a particular level. Simultaneously, the RO product water tank in the original design is removed, the RO product water is sent directly to the first-level desalinated water tank, and a duplex liquid alkali respirator is installed on the top of the middle to prevent secondary pollution of the RO product water by CO2 and other gases in the atmosphere.

3. Make the RO shutdown pure water flushing operation more effective

Forward osmosis is another method for flushing. When the RO system is turned off, pure water from the mixed bed's output is used to flush and replace the membrane surface. The product water on the RO product water side can be made to stop after the shutdown because the salt level of the pure water at the output of the mixed bed is significantly lower than that of the RO product water.

Begin to permeate the membrane and travel to the pure water side with low concentrations. Pollutants that have entered the membrane pores and adsorbed on the membrane surface are easily eliminated by water movement, and the concentration polarisation of the membrane surface can be lowered in the flowing condition. There is a reduce membrane surface contamination as a result of this phenomena.

4. Select an anti-pollution film

Although the purpose of feedwater pre-treatment is to reduce RO membrane surface pollution, bacteria and microorganisms in water will still cause RO membrane surface pollution due to changes in feedwater components and disturbances in feedwater pre-treatment conditions, especially when surface water is used as raw water.

The membrane surface becomes fouled and clogged, reducing the system's water production, increasing the pressure difference, increasing energy consumption, and lowering the membrane element's service life.

If you're searching for an industrial or a commercial RO plant manufacturer, get in touch with Netsol Water Solutions. We have the experience and expertise to help you find the best RO system for your intended application. We offer different capacities for Commercial and Industrial reverse osmosis equipment’s and can help you find a system that will be both cost effective and efficient to utilize.

You may reach us via phone at +919650608473 or by email at enquiry@netsolwater.com