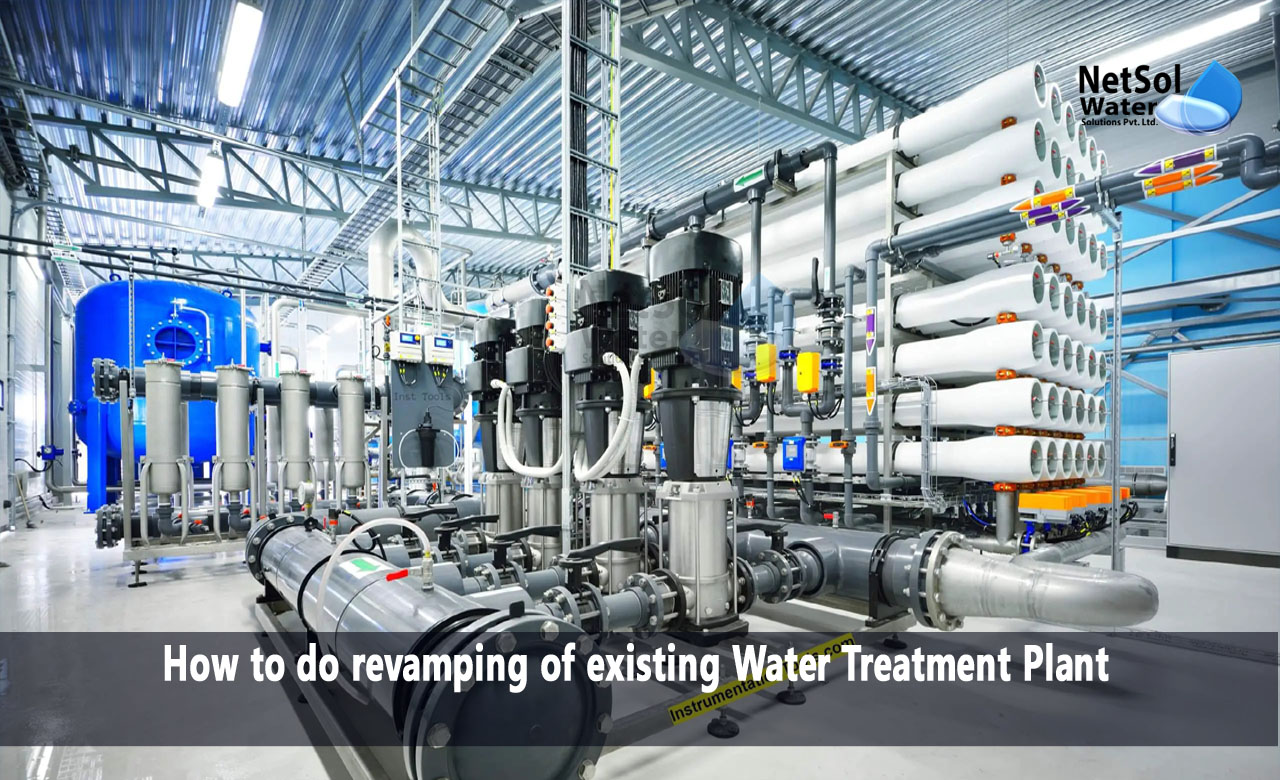

How to do revamping of existing Water Treatment Plant?

Water is a valuable resource, and maintaining its quality and availability is essential for environmental sustainability and public health. In this procedure, water treatment plants are essential because they clean untreated water from a variety of sources, including rivers, lakes, and groundwater, to make it fit for human use. A WTP must be updated to guarantee its long-term effectiveness, regulatory adherence, and ability to respond to changing needs.

Why Revamp a Water Treatment Plant?

Several variables may necessitate the revamping of a WTP:

a. Aging Infrastructure: A WTP's physical components can deteriorate over time, which can result in inefficiencies, higher maintenance costs, and possible health risks.

b. Changing Regulations: As environmental and water quality standards change, WTPs may need to modernize their procedures and tools to stay in compliance.

c. Population Growth: Growing populations may put more load on already-existing wastewater treatment plants, demanding their expansion and modernization.

d. Technological developments: New developments may provide more effective and affordable treatment options, driving upgrades.

Steps for Revamping a Water Treatment Plant

a. Planning and evaluation

A WTP's existing condition must be thoroughly evaluated before any changes can be made. This include assessing the equipment's state, studying data on water quality, and learning about the plant's operational past. Planning includeestablishing specific objectives for the renovation, some of which can be to increase capacity, increase water quality, or improve treatment effectiveness.

b. Compliance with regulations

Ensure that all rules governing water treatment that are local, state, and federal are followed. Consult with regulatory organisations to learn the essential authorizations and requirements for the renovation.

c. Engineering and design

Work together with engineers and industry professionals to redesign the WTP. This process entails creating thorough engineering designs, specifying hardware and supplies, and taking sustainability and energy efficiency into account.

d. Finance and Budgeting

Make a thorough budget that includes costs for design, construction, purchasing of equipment, and operational expenses. Investigate your financial possibilities, including grants, loans, and public-private partnerships.

e. Construction

Follow the approved design plans for the building phase. To do this, new equipment must be purchased, installed, and upgraded, as well as existing infrastructure, and all work must adhere to safety and quality requirements.

f. Testing and Commissioning

It is crucial to do thorough testing and commissioning to ensure that the updated WTP performs as expected. To find and fix any problems, do water quality tests, flow rate measurements, and system performance evaluations.

g. Development of the Workforce and Training

Teach the plant's employees how to use and maintain the new machinery and procedures. Long-term effectiveness of the WTP is ensured by investments in workforce development.

h. Impact analysis of the environment

Analyse the redesigned WTP's environmental impact and take any necessary mitigating steps. This may involve taking measures to cut back on trash production, conserve energy, and safeguard local ecosystems.

I. Observation and upkeep

Implement a thorough monitoring and maintenance programme to guarantee the WTP's continued effectiveness and durability. Key elements include frequent inspections, preventive maintenance, and data analysis.

j. Engagement in the Community

Engage the neighbourhood to share updates on the renovation project and to address any issues. Keeping lines of communication open and transparent promotes support and trust.

Challenges and Considerations

Cost: Upgrading a WTP can be costly, and money can be difficult to come by, particularly for smaller communities.

Downtime: The facility may need to be temporarily shut down as part of the renovation process, which could affect the water supply. Alternative water sources should have backup plans in place.

Regulatory Obstacles: It can take a lot of time and effort to navigate complicated regulations and permitting procedures, which can cause delays.

Environmental Impact: Reducing the renovation's negative impact on the environment is key, and it's also important to resolve any potential ecological issues.

Conclusion:

It takes a lot of work to update an existing water treatment facility, but doing so is essential to maintaining the supply of clean and safe drinking water. It requires meticulous preparation, adherence to rules, and the incorporation of cutting-edge technologies. Communities can protect their water supply for future generations by addressing ageing infrastructure, adjusting to new rules, and embracing creative solutions.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.