What are tricking filters?

A trickling filter is a sort of waste water treatment procedure with a growing process associated to it. The bacteria that are responsible for digesting are coupled to an inert filter material in this process. Rock, gravel, sand, and a variety of plastic and other synthetic materials can all be used as packing material. In other words, the absorption and adsorption of organic elements by the layer of microbial bio-film is required for the removal of contaminants from waste water. Typically, the packing material is chosen to produce a high surface area to volume ratio. It's also referred to as a trickling bio-filter, a trickle filter, a bio-filter, and a biological filter.

What is the process involved in trickling filters?

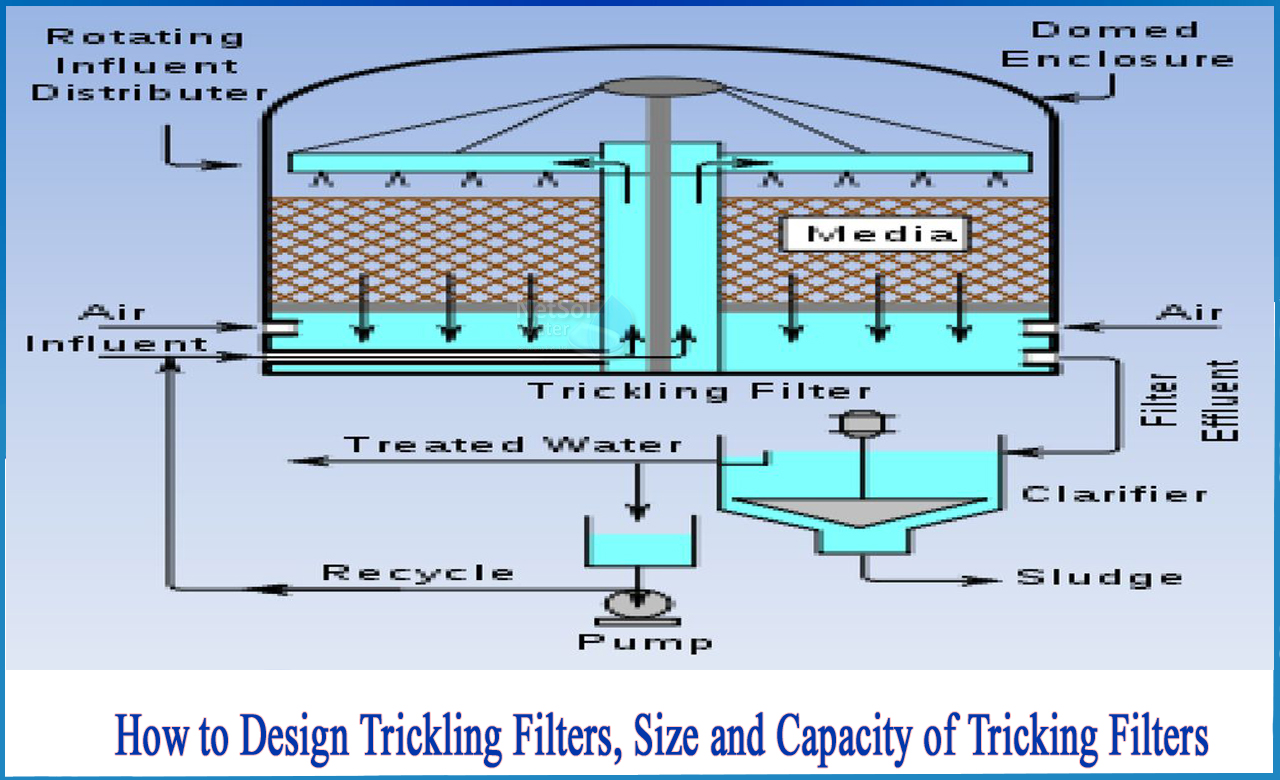

>In a trickling filter, wastewater is spread over the top of a tank containing non-submerged packing material.

>The bacteria forming as an attached biofilm requires oxygen, which is provided by air circulation in the empty area, either by natural draught or by blowers.

>During operation, the biomass connected to the medium metabolises the organic material present in the wastewater. As organic materials extracted from running wastewater is synthesised into new cellular material, the biological slime thickens.

>The depth of oxygen penetration into the microbial layer limits the thickness of the aerobic layer.As a result of the increasing thickness of the slime layer, the microorganisms near the medium face enter the endogenous phase as the substrate is metabolised before it can reach them, and they lose their capacity to cling to the media surface.

>The liquid then washes the slime off the medium, prompting the growth of a fresh slime layer. Sloughing is the term for the process of shedding the slime layer.

>An underdrainage collects the sloughed-off film and treated wastewater while also allowing air to circulate via a filter. The collected liquid is pumped into a settling tank to separate the solids from the liquid.

What are the design considerations for tricking filters?

These are classified as high rate or low rate, based on organic and hydraulic loading applied to the unit.

S.no. |

Design Feature |

Low Rate Filter |

High Rate Filter |

|

1. |

Hydraulic loading, m3/m2.d |

1 - 4 |

10 - 40 |

|

2. |

Organic loading, kg BOD/m3.d |

0.08 - 0.32 |

0.32 - 1.0 |

|

3. |

Depth, m. |

1.8 - 3.0 |

0.9 - 2.5 |

|

4. |

Recirculation ratio |

0 |

0.5 - 3.0 (domestic wastewater), Up to 8 for strong industrial wastewater |

How to design trickling filters?

In most cases, empirical relationships are used to determine the required filter volume for a given degree of wastewater treatment.

Equations from the National Research Council (National Research Council of USA)

1-The equation of Rankins

2-Eckenfilder's formula

3-Equation of Galler and Gotaas

The formulae of Rankin's is frequently employed.

When there is no recirculation, seasonal temperature variations are small, and swings with high organic loading are small, the NRC equations provide adequate results.

For highrate filters, Rankin's equation is employed.

a)-NRC equations: These equations can be used to calculate both low and high rate filter size and capacity in terms of volume.

E2 is the efficiency of a single stage or first stage of a two-stage filter.

E2= 100/ {1+0.44(F1.BOD/V1.Rf1)1/2}

For the second stage filter, the efficiency E3 is given by

E3=100/ {[1+0.44/ (1- E2) (F2.BOD/V2.Rf2)1/2]}

Where E2 denotes the percent effectiveness of a single stage or first stage of a two-stage filter in removing BOD, and E3 denotes the percent efficiency of the second stage filter.

(F1.BOD) is BOD loading of settled raw sewage in single stage filter in kg/d,

{F2.BOD= F1.BOD (1- E2)} is BOD loading on second-stage filter in kg/d,

{F3.BOD= F1.BOD (1- E2)} is BOD loading on third-stage filter in kg/d,

{F4.BOD= F1.BOD (1- E2)} is BOD loading on third-stage filter in kg/d,

Rf1= Recirculation factor for first stage, R1= Recirculation ratio for first stage filter;

Rf2= Recirculation factor for second stage, R2= Recirculation ratio for second stage filter;

V1= Volume of first stage filter, m3;

V2= Volume of second stage filter, m3;

b)-Rankin’s equation: This equation, also known as the Tentative Method of Ten States USA, has been successfully applied over a wide temperature range. For single stage filters, the following requirements must be observed:

-The amount of BOD-5 applied to filters from raw settling residential sewage should not exceed 1.2 kg BOD-5/day/m3 filter volume.

-The hydraulic load should not exceed 30 m3/m2 filter surface-day (including recirculation).

-The recirculation ratio (R/Q) should be set so that the BOD entering the filter (including recirculation) does not exceed three times the BOD predicted in the effluent. This means that, as long as the foregoing conditions are met, efficiency is just a function of recirculation and may be calculated as follows:

E = (R/Q) + 1

(R/Q) + 1.5

This is a simple method of designing trickling filters and we at Netsol Water customize various reactors and treatment plants for different industries, and residences.