How to Design Commercial RO Plant?

Effective water treatment is critical for businesses ranging from car washes to hotels to hospitals. Whether it's drinking water for vending machines and restaurants or food-grade water for processing, end users are looking for solutions that can meet their water treatment needs efficiently and affordably. Therefore, the price determines the commercial system design. Concentrate recirculation, pre-filter inlet and outlet pressure gauges, pump throttling valve, soft motor starter or variable frequency drive, FRP vessels, so-called "cold water" membranes, and permeate pressure gauges can all be included if the buyer is educated on the benefits.

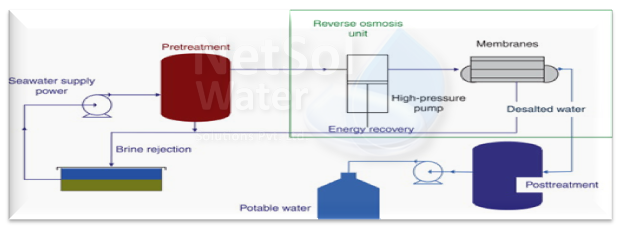

Commercial systems should be pre-treated with a multimedia filter, softener, and activated carbon filter. The backwashable filter and softener vessels are made of fibreglass reinforced plastic (FRP) and are controlled by a timer. The RO system should have a "Big Blue" style plastic housing with a five-micron pre-filter and a 304 stainless steel multistage pump. Concentrate flow is controlled by a stainless-steel needle valve, while permeate flow varies. Some parts may be brass rather than stainless steel, depending on the manufacturer. This design is based on competitive pricing pressures as well as the low cost of RO membranes.

It takes a lot of skill to design small commercial RO systems. There are numerous considerations and assessments to be made, such as:

- 1. Sizing the System: The majority of commercial RO systems work in tandem with a storage tank. It can be difficult to accurately calculate the balance between the system size and the storage tank size. Therefore, as per the needs of the user, gal per day will be calculated then only size of the system will be decided, whether RO system needs small storage filter or RO needs large storage system.

- 2. Membrane System Guidelines: As permeate flows across the membrane, the feed water flow rate decreases because it becomes concentrated with high scaling and fouling containments the further across the membrane surface it flows. The fouling proclivity of feedwater has the most impact on membrane system design. Membrane fouling can be caused by a variety of materials found in feedwater and concentrated at the membrane surface, including dissolved organics, bacteria, particles, and other colloidal material.

The pre-treated feedwater's silt density index value can be used as a surrogate measure of the fouling material. A minimum flow is required to maintain high velocity and turbulence on the membrane surface in order to minimise fouling or scaling of the concentrate containments. By mixing feed water with rejected concentrate water, the concentrate recirculation option allows for higher recoveries and less wastewater.

- 3. Determining Size with TCF: Alternatively, some businesses may look for pre-built systems, which are typically rated in gallons per day produced at 77oF. If design comparisons are performed at a different temperature, a correction factor must be used. A TCF table is the best way to determine the proper unit size. Some businesses only install and maintain commercial RO systems. In this case, they must be able to size a 77o F system for a customer site where temperatures may vary.

- 4. Reliable Performance: Many OEMs within small to medium businesses rely on a water treatment system that can meet growing demands cost-effectively, without creating inefficiencies or harming productivity, whether they are designing a RO system to achieve a spot-free car wash or quality drinking water for hospitals or buildings.