What is a belt filter?

The belt filter (also known as a belt press filter or belt filter press) is a type of industrial machine used for solid/liquid separation operations, including sludge dewatering in the chemical industry, mining, and water treatment. Belt filter presses are also used in apple juice, cider, and winemaking. Filtration is accomplished principally by passing a pair of filtering cloths and belts via a roller system. As a feed, the system separates sludge or slurry into a filtrate and a solid cake.

Applications of belt filter

The belt filter is mostly used for sludge and slurry dewatering, as well as juice extraction from apples, pears, and other fruits, as well as grapes for winemaking. Belt filters are employed in a variety of municipal and industrial applications, such as urban sewage and wastewater treatment, metallurgy and mining, steel plants, coal plants, breweries, dyeing, tanneries, and chemical and paper manufacturers.

A belt filter's uses are restricted to the sludges, slurry, or crushed fruit that it can treat. Municipal sludges comprise raw, anaerobically and aerobically digested sludges, alum sludge, lime softening sludge, and river water silt.

Food processing wastes, pulp and paper wastes, chemical sludges, pharmaceutical wastes, industrial waste processing sludges, and petrochemical wastes are all sources of sludge or slurry in industry.

Mixed sludge, mineral slurry, dust sediment, chosen coal washing mud, biological sludge, primary sludge, and straw, wood, or waste paper pulp are examples of these wastes.

What are the goals of sludge dewatering?

Some of the goals of dewatering include reducing volume to reduce transport and storage costs, removing liquids before landfill disposal, reducing fuel requirements before further drying or incineration, producing adequate material for composting, avoiding runoff and pooling when used for land applications, and optimizing other drying processes.

Belt filters are built individually for each of these applications and feeds.

What factors influence BFP's performance?

The BFP's total performance is determined by the feed sludge source and properties, as well as the dosage circumstances. Primary sludges, both raw and anaerobically digested, are more easily filtered than waste activated sludge, as with all other thickening and dewatering procedures (WAS).

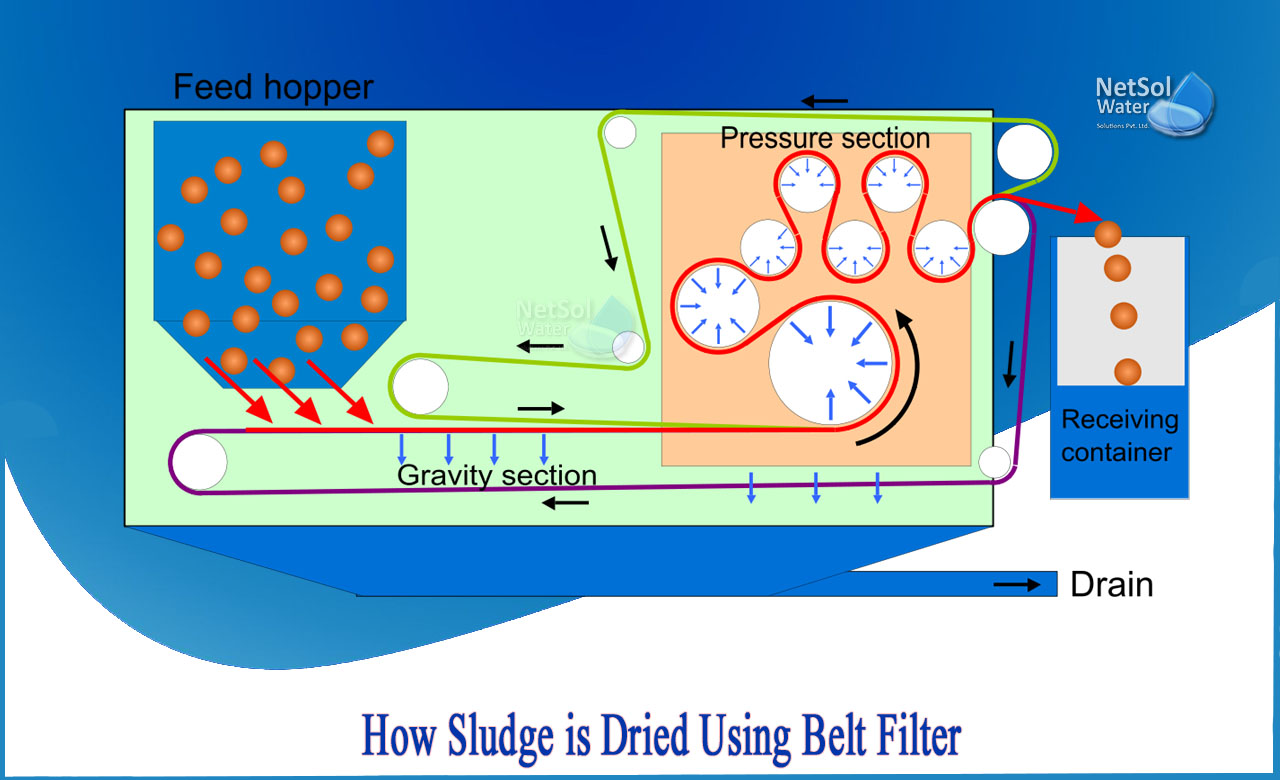

How sludge is dried using belt filter?

A belt filter press (BFP) dewaters sludge by pressing it to drive water through a porous material.

In the case of primary sludge, the procedure yields a cake (the dewatered product) with a dry solids (DS) percentage of 30% or more. This differs from the lower-energy gravity belt thickening technique, which reaches a maximum DS content of 10%.

To remove water, a BFP successively combines drainage and mechanical pressure. The machinery typically consists of 23 recirculating belts, with two belts merging at some point to compress and squeeze water from the sludge.

As with a gravity belt thickener, the conditioned sludge feed is initially transported down a gravity drainage portion of one of the porous belts. It is then subjected to pressure as it travels between two recirculating belts, which create a wedge zone at the intake and travel over a roller.More water is released as a result of the squeezing action of the two belts in this pressure zone.

Many belt filter press systems include a second pressure zone made up of a set of rollers through which the two belts travel while the sludge solids are kept between them. The rollers in this high-pressure zone strain the belts, exerting shearing and compressive forces on the sludge, causing it to release even more water.

Some BFP technologies use a three-belt system, with the gravity belt operating independently of the two pressurizing belts. This permits the thickening operation's recirculation rate to be controlled independently of the dewatering process.

The belts, like the gravity belt thickener, are cleaned using water spray to prevent blockage of the filter belt pores. The filtrate is mixed with the waste wash water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.