What are ions?

Ions are electrically charged atoms or molecules present in water, with a net positive or negative charge. These ions are regarded as contaminants, in many applications that utilize water as a rinse or ingredient, and must be eliminated from the water.

In this blog, we will describe about the types of ions, de-ionization, and the methods for the de-ionization of water.

Cations and Anions

Ions with positive charges are referred to as "cations," whereas ions with negative charges are referred to as "Anions." Ion exchange resins are used to exchange unwanted cations and anions, with hydrogen and hydroxyl, resulting in pure water (H20).

The following is a list of ions that are typically present in municipal water.

|

Cations (Removed by Cation Resins) |

Anions (Removed by Anion Resins) |

|

Calcium (Ca++) |

Chlorides (Cl-) |

|

Magnesium (Mg++) |

Sulphates (SO4--) |

|

Iron (Fe+++) |

Nitrates (NO3-) |

|

Manganese (Mn++) |

Carbonates (CO3--) |

What is deionized water?

Minerals in water can interfere with numerous analytical procedures and chemical reactions. De-ionized water is water that has had the minerals extracted from its molecules, and is regarded to be purer than tap water.

It is similar to distilled water in some aspects, but the deionization system is faster, and has the added benefit of minimizing scale building in pipes. Deionization does not eliminate germs or viruses that may be present in water.

Use of deionized water

Deionized or demineralized water is most commonly used in laboratory testing, electronics manufacturing, food processing, cosmetics, pharmaceuticals, big aquariums or fish tanks, and other industrial water uses.

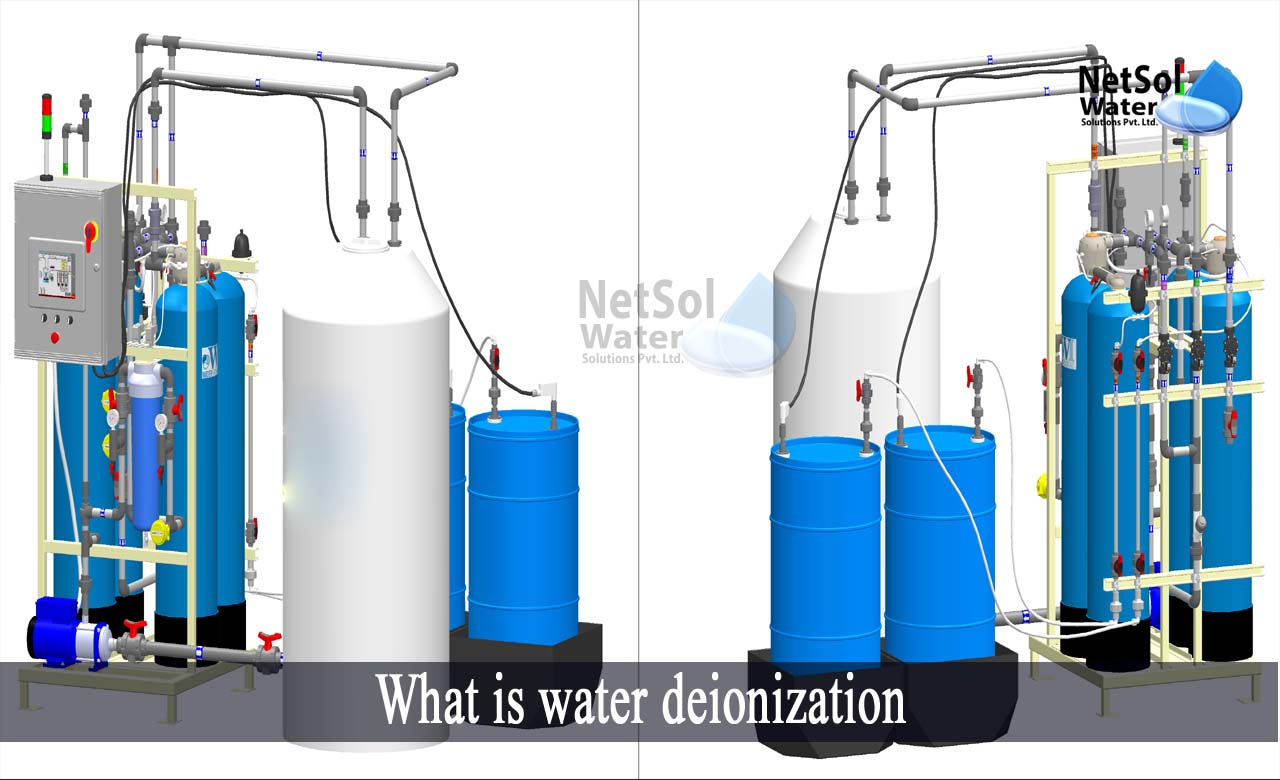

What is water deionization?

Water deionization, also known as "demineralization," is a water purification process that eliminates two types of ions:

- Positively charged "cations", and

- Negatively charged "anions."

Process of deionization

Deionized water systems, like water softener systems, employ an ion exchange process that incorporate tiny plastic resin beads, with positive or negative charges. When water is driven through the resin bed of a deionization system, which is normally in the form of a column or tank, the mineral particles connect to the resin beads with the matching electrical charges, and remain attached until the ions are eliminated.

What is regeneration?

Regeneration is the process of regenerating the resin bead using caustic acid, which eliminates the collected ions and flushes them out of the system. The ion exchange resins will then be ready to begin deionization.

Reverse osmosis and water deionization

Reverse osmosis, a water filtering system, forces tap water through a semipermeable membrane, to remove hard water mineral deposits and other impurities. It is frequently used in combination with water deionization.

Water Deionization Methods

Water deionization can be accomplished in 3 ways.

• Ion Exchange: Co-current deionization involves water and regeneration chemicals, entering at the top of an ion exchange column and exiting at the bottom.

• Separate Bed System: In counter-current deionization, water is pumped from the top and regeneration chemicals are pumped from the bottom, or vice versa. When compared to co-current deionization, counter-current requires less time for the regeneration process, resulting in fewer regenerants and reduced total costs.

• Mixed Bed System: In a single ion exchange column, a 50/50 combination of cation and anion resin is used for mixed bed deionization. This procedure frequently necessitates a sophisticated regeneration process, which increases the expense but generates the most highly filtered water.

Demineralization plants by Netsol Water

Deionization systems implemented by water treatment service providers, remove minerals and lead, to improve purity of water, by removing ions with positive and negative charges. Netsol Water supplies the best deionization water systems, which produces liters of very clean water, for domestic and industrial purposes.

Applications of deionized water

The uses of deionized water to avoid corrosion are virtually limitless and include, among other things, the following:

• Woodworking or metalworking machines,

• Material-transporting pipes,

• Ship hulls, notably naval vessels,

• Cars, aircraft, and trains,

• Metal fencing, etc.

Conclusion

Deionized water is still being studied, to see how effective it is at reducing corrosion in metal items. Non-deionized water pollutants are natural salts that react with the metals, to create corrosion and breakage. Deionized water should be effective in avoiding corrosion, because it has significantly less of these pollutants. In practice, findings vary greatly based on a variety of conditions, and more definitive testing is required.