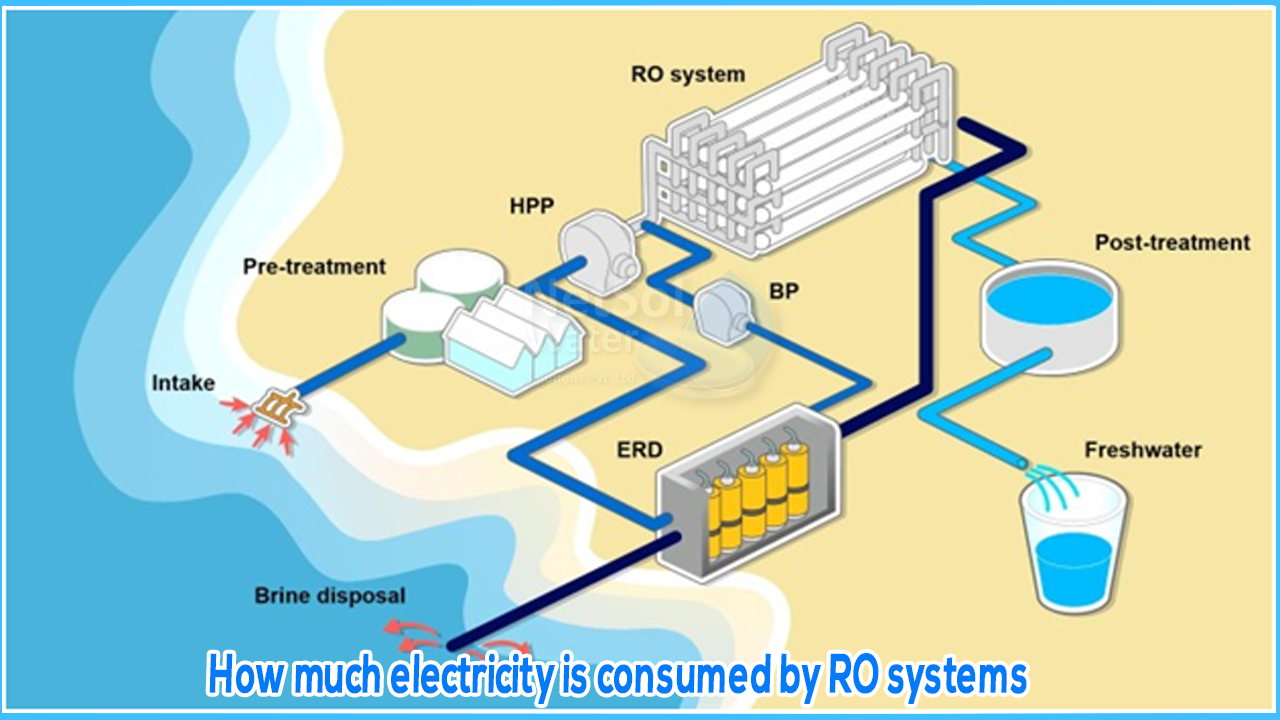

Reverse osmosis, or RO, is a sophisticated water purification process that was first developed by the United States Navy to create drinking water for submarine sailors from saltwater. It's a membrane filtration system that operates by forcing water through microscopic pores in a semi-permeable membrane under pressure. To generate highly purified great-tasting water, modern RO-systems for the home combine membrane technology with carbon and mechanical filtering are used.

The procedure has become increasingly sophisticated over time. Reverse osmosis, in which water is pushed at high pressure across semipermeable membranes, remove salt and other minerals, and is used in most modern desalination plants.

More than 17,000 desalination units in 150 countries provide freshwater to around 300 million people worldwide. Out of necessity and energy availability, Middle Eastern countries have dominated that industry, but as worries of freshwater shortages expand around the world, others are quickly entering their ranks.

ELECTRICITY USAGE of RO Plants

Reverse osmosis plants around the world consume more than 200 million kilowatt-hours each day, with energy costs an estimated 55 percent of plants, total operation and maintenance costs. It takes most reverse osmosis plants about 3 to 10 kilowatt-hours of energy to produce one cubic meter of freshwater from seawater. Traditional drinking water treatment plants typically use well under 1 kWh per cubic meter and can cause environmental problems, from displacing ocean-dwelling creatures to adversely altering the salt concentrations around them.

Reverse osmosis, a typical desalination process, is costly because it requires a lot of electricity to drive water through a filter. The cost of treating the water to remove germs and replacing the filters is likewise high. Improved membrane materials, researchers hope, will make this procedure less expensive. The cost of energy is one of the key elements impacting the total cost of water production by any type of desalination process.

To create one cubic metre of freshwater from seawater, a reverse osmosis plant typically requires 3 to 10 kWh of electric energy. The fixed costs in a conventional reverse osmosis desalination plant are another key aspect that contributes to the total cost. The fixed cost is determined by a number of factors, including the location of the factory and the technology used.

HOW THE ENERGY CONSUMPTION CAN BE REDUCED?

Research into a suite of seawater desalination improvements is underway to make the process cheaper and more environmentally friendly, including reducing reliance on fossil fuel–derived energy, which contributes to climate change, which in turn contributes to freshwater shortages in the first place, perpetuating the vicious cycle.

The idea of using renewable energies to operate desalination plants with the aim of both meeting the future water demand and satisfying the electricity(energy) reduction is becoming increasingly attractive.

Some of the examples who have been showing process in energy saving are:

1.Solar powered desalination plant in Egypt

2. Solar powered desalination plant in Jordan

3. Solar powered desalination plant in Australia

4.Wind powered reverse osmosisplants in Norway

5. Wind powered reverse osmosis plant in Australia