What is an Equalization tank?

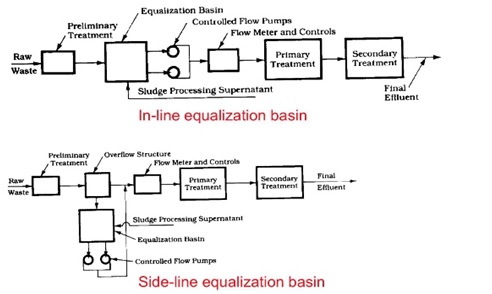

Flow equalisation tanks are used to regulate fluctuating influent flows to a wastewater treatment plant caused by diurnal variation and wet weather events. Mixing is necessary in these basins to maintain solids suspended, prevent deposition, and equalise load to the treatment plant. The tank is rectangular in shape to accommodate the installation of air diffusers to just provide complete floor coverage.

Main function of the Equalization tank

The equalisation tank's main function is to act as a buffer, collecting raw incoming sewage at widely fluctuating rates and passing it on to the bottom of the sewage treatment plant at a stable flow rate.

Flow equalisation is a method of controlling hydraulic velocity, or flow rate, through a wastewater treatment system. Flow equalisation inhibits high-volume incoming flow from pushing solids, surges of short-term and organic material, and other contaminants out of the treatment process. Flow equalisation also controls the flow through each stage of the treatment system, allowing for physical, biological, and chemical processes to take place.

Detailed theory of Equalization tank

-The filtered sewage from the Bar Screen Chamber is carried by the inlet pipe.

-In the tank, sewage is gathered. The level varies throughout the day because, while the incoming rate varies greatly, the outgoing rate remains constant.

-The sewage is moved to the aeration tank by raw sewage lift pumps.

-The sewage is delivered to the aeration tank via the delivery pipe.

-Coarse bubble diffusers are short lengths of tubes with holes spaced at regular intervals. They blow large bubbles into the tank to lightly aerate the sewage and to continuously agitate the mix. The tank has 7 diffusers strapped to cement blocks to keep the assembly firmly anchored in place. Diffusers can also be used in pairs or individually.

-This air supply pipeline transports compressed air. This could be either a rigid pipe or a flexible hose. It is more convenient, however, to use completely separate pairs of diffusers, each with its own air pipe (flexible hose).

Benefits of Equalization tank

There are numerous advantages to incorporating flow equalisation into a residential treatment system:

>Gravity separation of solids is greatly enhanced in the case of a septic tank or pre-treatment tank.

>Eliminating hydraulic surges in a secondary biological or chemical treatment system ensures adequate process retention time and a much higher degree of treatment.

>Clarifiers that have undergone secondary treatment will have improved solids separation and effluent quality. When a filtration device is used, solids loading to the filtration device is reduced, resulting in longer filter life and higher effluent quality.

>More consistent loading, equalisation of surge flows, and removal of excess solids improve the operation of a downstream sand filter, media filter, or constructed wetland.

>Since organic and hydraulic surges are eliminated and system overloading is avoided, all types of effluent disposal systems, including tile fields, mounds, and irrigation systems, will operate longer and more efficiently.

Conclusion

Netsol Water is intended to be energy-efficient while also allowing for significant variation in operating water levels. Aerated Mixing System for equalisation tanks provides energy-efficient aeration and mixing for mixing limited applications.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.