How is Sludge Piping done for Pumps?

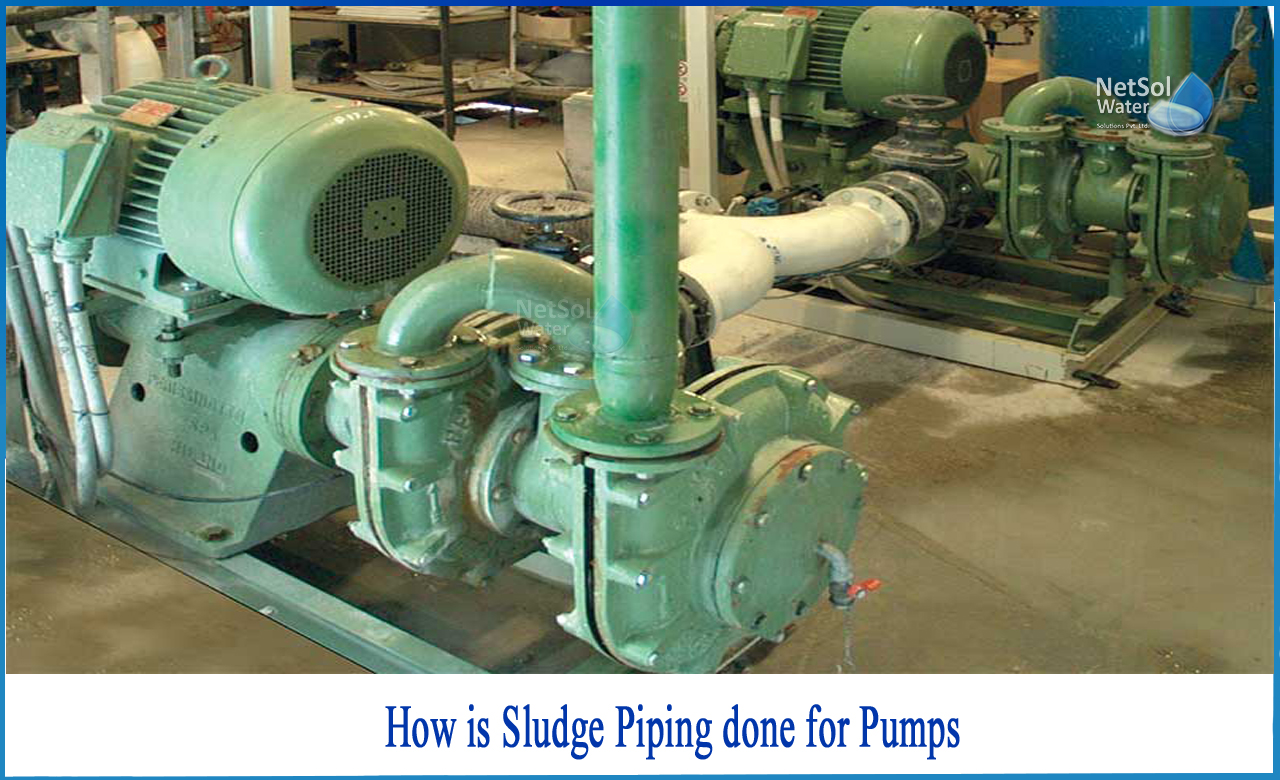

Sludge pumping stations are designed to lift wastewater to higher elevations. The sewage pumps are of two types, namely, horizontal axis driven with impeller rotating in the vertical pane or vertical axis driven with impeller rotating in the horizontal plane. After selecting the type of pump, the next important thing is to design the pipeline to and from the pumps.

Pumps and other mechanical devices in the treatment environment should be constructed for prolonged usage since they will be mistreated by climatic conditions and the corrosive atmosphere.

Types of Sludge Pumps

1) Centrifugal pumps;

2) Air lift pumps;

3) Archimedean screw pumps;

4) Reciprocating pumps of the plunger type or of the diaphragm type;

5) Centrifugal screw.

Design of sludge piping

S?ewage and sludge conduits, drains, and water lines, as well as chemical process pipework, are all required in sewage treatment facilities.

Design: The design of the piping is to be based on the sludge-handling rate, the desired velocity of the flow of the sludge, the possible layout and arrangement of the piping, etc.

Material: The material for piping and pumps should be corrosion and abrasion resistant. Sewage sludge flows like a thin plastic material and hence the formulae for the flow of water are not applicable.

Velocity: The velocity of flow should be in the critical range above the upper limit of the laminar flow and below the lower limit of the turbulent flow, in order to avoid clogging and deposition of grease, so that the application of the hydraulic formulae for flow of water becomes permissible. In general velocities between 1.5 to 2.5 m/s are satisfactory.

Head losses: The frictional head losses in the sludge pipe can be estimated by applying the Hazen-William’s formula, adopting the ‘C’ value between 40-50 depending on the material to be used. The lower value is adopted for high solid content of the sludge. Pipes less than NB 200 should not be used for gravity withdrawal or for the suction lines topumps.

Slope: In order to take care of thin sludge to flow by gravity for short distances within the treatment plant, a 3% or greater slope should be adopted.

Suction and discharge: It should be arranged in such a way that their lengths are as short as possible, straight and with minimum bends. Adequate provision should be made to facilitate cleaning.

Other appurtenances: Large radius elbows and sweep tees are usually adopted for change in direction. To avoid gas pockets, high points should be avoided as much as possible. For all pipes travelling through masonry, a suitable recess and sleeves are normally supplied. Double-flanged pipes are usually adopted for sludge-lines. Valves should be provided at selected locations to clean the lines.

What can we offer?

Netsol Water is one of India's major water and wastewater management company, specialized in the design, manufacture, and delivery of custom-made treatment systems, industrial machinery, and luxury amenities for the water industry. We can customize WTPs/WWTPs that will cater to all needs and at the same time effectively treat different types of wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.