What is sludge?

Sludge is a semi-solid leftover byproduct of industrial or refining operations. It is a separated solid floating in a liquid, with significant amounts of interstitial water between the solid particles. This material can be dried to lower its volume and the moisture level of the biosolids in the sludge.

Methods of Sludge Treatment

Sludge generated by wastewater treatment is divided into two types: raw main sludge and secondary sludge. The methods most typically employed to process the sludge formed during wastewater treatment are detailed here.

How is sludge dried using vacuum filters?

This is essentially a thermal drying technique in which heat energy is applied to the sludge in order for it to evaporate water. The drying process decreases the amount of the product, making it simpler to store, transport, package, and sell.

There are two ways for drying sludge: direct and indirect. However, indirect heat drying is becoming more common as a method of reducing sludge volume by eliminating moisture and achieving a dry solids percentage of 90%. The technique has a low environmental effect and yields a stable dry granular product that is easy to store, distribute, and use in agriculture.

Applications for Sludge Drying

Dried or processed sludge has a wide range of uses, the most common of which is agricultural field application. When the drying process to make biosolids is done, the biosolids operate as a fertilizer for crop harvesting. Crops absorb the organic nitrogen and phosphorus present in biosolids very efficiently since these plant nutrients are supplied gradually during the growing season. As the crop matures, it will be able to absorb these nutrients.Besides the application of crop harvesting, the treated sludge can also be used as top dressing on golf course fairways, soil conditioner for construction of parks, and other athletic fields, a soil substitute in final landfill cover, etc.

What is vacuum dehydrator?

The vacuum dehydrator was the first dehydrator introduced in Japan, however it requires a huge amount of inorganic flocculant and the moisture content of the dehydrated cakes does not fall as much as other types of dehydrators.

There are several types of dehydrators for sludge generated by wastewater treatment facilities.

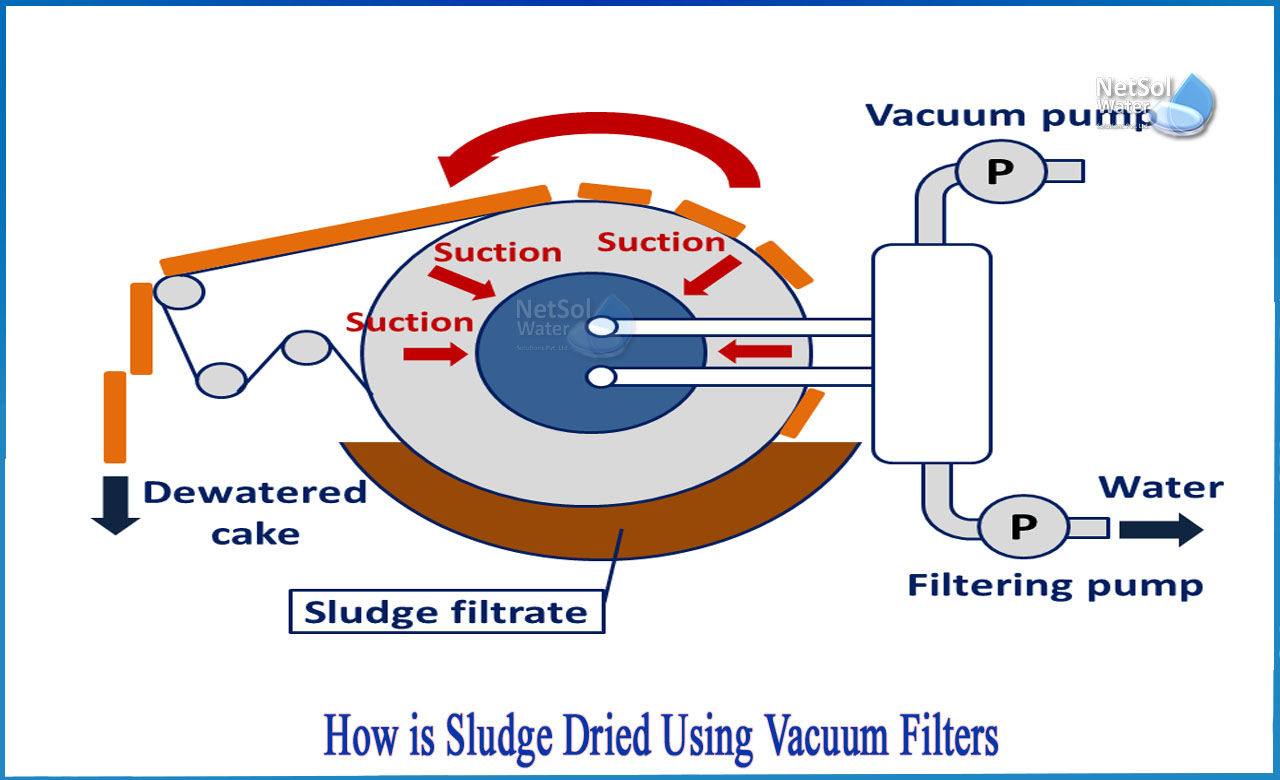

Among these, a vacuum dehydrator uses a vacuum pump to create negative pressure within the drum and then filters and dehydrates the sludge by placing it on a filtering cloth attached to the revolving surface of the drum. A vacuum dehydrator features a revolving drum covered by filtering cloth, and vacuum pumps produce negative pressure inside the drum. When the drum spins, a portion of the drum is soaked in sludge filtrate, and the sludge is dragged toward the surface of the filtering cloth, where it is filtered and dehydrated while sticking to the filtering cloth. Sludge is shaped like cakes and peeled off from the filtering cloth after being dehydrated.

Advantages of Vacuum Filters

1. Vacuum Filters are almost maintenance-free,

2. Vacuum Filters eliminate a large amount of sludge,

3. This results in cheaper production costs,

4. Continuous functioning, resulting in less downtime

Conclusion

Netsol Water is the top producer of water and waste water treatment facilities in India. Along with sludge drying, we manufacture a wide range of technologies that may be employed in waste water technologies. Vacuum Filters can be designed or customized to meet the needs of the client in both permanent and disposable media variants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.