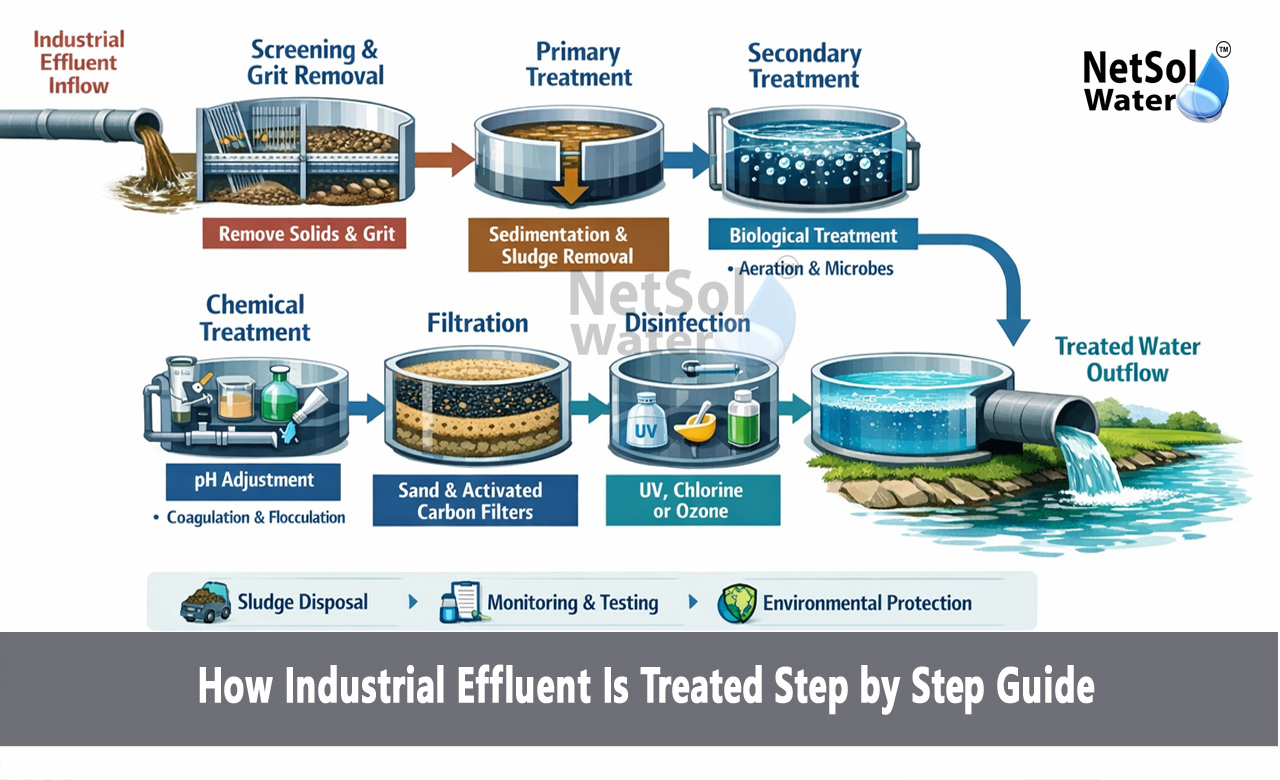

How Industrial Effluent Is Treated? Step by Step Guide

Industrial areas are known for their factories, workshops and their heavy use of water. These areas often generate wastewater that contains oils, chemicals and suspended solids. Treating this water before releasing it protects rivers, lakes and groundwater and it helps companies follow the law and avoid fines. An Effluent Treatment Plant plays an important role in this work. Netsol Water is the leading Effluent Treatment Plant Manufacturer and we design plants that match the needs of each factory.

1: Preliminary Treatment and Screening

Preliminary treatment sets the stage for the rest of the process and it prevents damage to pumps and downstream units. It removes large objects, floating material and heavy grit. Let us have a look on some common tasks in this stage and how they protect the plant.

(a) Screening and Grit Removal

Screens stop large items such as rags, plastic sheets and wooden pieces from entering the main tanks. A coarse screen catches the largest pieces and a fine screen captures smaller solids. The plant cleans the screens often to keep flow steady. After screening the flow moves to grit removal. Grit consists of sand small stones and metal filings. These particles sink quickly and they scratch pumps and wear mechanical parts. A grit chamber slows the water so grit settles to the bottom. Operators remove grit regularly and send it for disposal. Proper design here reduces wear and it lowers maintenance time.

(b)Equalization and Flow Conditioning

After grit removal the water often goes to an equalization tank. This tank evens out variations in flow and strength of the wastewater. Factories may release high loads during some hours and low loads during others. The equalization tank keeps the biological and chemical processes steady by providing uniform feed. Here the plant may mix the water and add timers to control release rates. Equalization helps biological units perform better and it reduces chemical use later. This step also protects the plant from shock loads that can upset bacteria and reduce treatment efficiency.

2: Primary and Secondary Treatment

Primary and secondary treatment remove settleable solids floating fats and organic matter that biological systems can break down. This stage shapes the quality of water that moves to advanced polishing. Let us have a look on some common methods and how they reduce pollution.

(a) Primary Sedimentation and Oil Removal

Primary sedimentation tanks give solids time to sink and oils time to rise. Heavy particles form a layer at the bottom that technicians call sludge. Lighter oils and grease float to the surface where skimmers remove them. The tank design ensures slow flow so particles settle rather than stay suspended. Removing these fractions early reduces the load on biological units that follow. The sludge from the bottom needs separate handling and it moves to thickening or digestion. Proper primary treatment makes the biological step more stable and it reduces chemical demand in later steps.

(b) Biological Treatment and Aeration

Biological treatment breaks down dissolved organic matter using microbes. These microbes need oxygen and a stable environment. Aeration tanks keep oxygen levels high and they mix the water so bacteria contact the organic material. The process turns soluble pollution into more biomass that settles out. After aeration the flow moves to a secondary clarifier where the biomass settles and returns partly back to the aeration tank. Systems may use activated sludge moving bed biofilm reactors or other biological methods based on the wastewater type. Choosing the right method depends on space available and on how strong the wastewater is. Biological treatment does most of the organic load removal and it prepares the water for final polishing.

3: Tertiary Treatment Disinfection and Sludge Handling

Tertiary treatment finishes the task and it ensures the treated water meets discharge or reuse quality. This stage removes remaining nutrients suspended matter and pathogens. Let us have a look on some common tertiary steps and the role of sludge handling in the full process.

(a) Filtration and Chemical Treatment

Filtration removes fine particles that did not settle earlier. Plants may use sand filters multimedia filters or membrane units to polish the water. Chemical dosing can remove nutrients such as phosphorus and reduce color and odor. Coagulants make small particles stick together so filters can capture them. In some plants membranes act as a last barrier and they can deliver high quality water suitable for reuse. Operators monitor pressure and turbidity to keep filters working well. Careful chemical control reduces overuse and it lowers cost. This stage makes the treated water clear and stable for final disinfection.

(b) Disinfection and Sludge Management

Disinfection kills remaining germs before the water leaves the plant. Common methods include chlorination UV systems and ozone units. The choice depends on local rules and on whether the water will be reused. Sludge from primary and secondary steps needs careful handling. Plants thicken sludge then dewater it and finally stabilize it through digestion or heat drying. Proper sludge care reduces odor transport cost and environmental risk. Some plants recover energy from sludge or they use it as a soil amendment when rules allow. Managing sludge well completes the treatment cycle and it keeps the plant safe for workers and nearby communities.

Conclusion

Good industrial wastewater control protects people and the environment and it keeps factories in business. An Effluent Treatment Plant that follows clear steps gives reliable results. Netsol Water is the leading Effluent Treatment Plant Manufacturer and we help clients choose design options that match their needs. For advice on plant design operation or retrofit contact Netsol Water to request a consultation.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com