How Does Sedimentation Work in Sewage Treatment Plants?

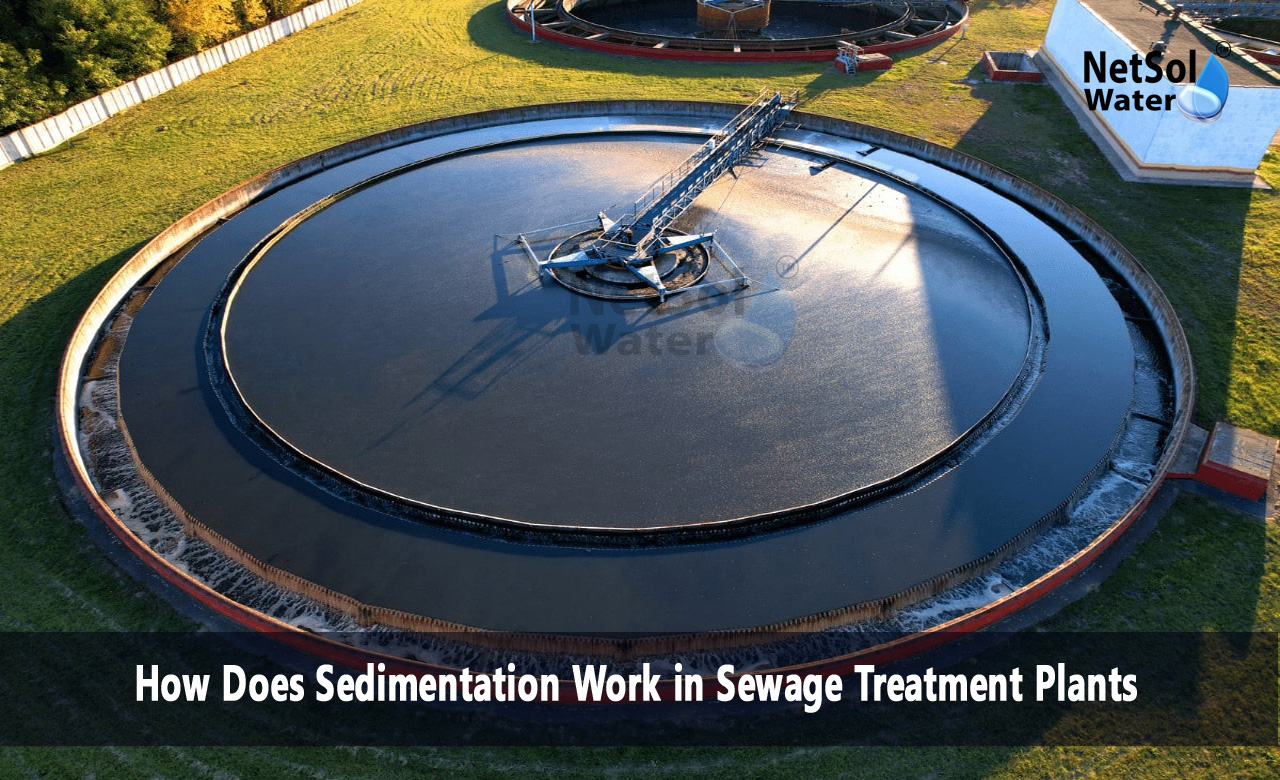

In every sewage treatment plant the process of sedimentation plays a key role. In this stage particles move out of wastewater by gravity. Clear water moves on to further treatment. Solids settle at the bottom of a tank. Removing these solids reduces the load on later steps. This stage makes the plant more efficient. It also cuts operating costs. Netsol Water offers clarifiers that match each client’s needs. Our units ensure reliable removal of settleable solids. They perform well under diverse flow rates and loads.

We explain how sedimentation in sewage treatment plants works. We look at its basic steps and key design points. We then cover factors that affect performance. Finally we share best practices for smooth operation.

Sedimentation Process

Sedimentation in sewage treatment plants begins with settling. Solids must fall out of water in a controlled way.Sedimentation means particles sink by gravity. Wastewater enters a still tank. Heavy matter sinks. Lighter material stays in suspension. This step gives clear water that moves on.

Mechanism of Particle Settling

Particles move down in calm water. Small particles move slowly. Large particles fall fast. Water above stays clear. The shape and density of particles affect speed. The tank depth and flow rate also matter.Understanding this process helps in choosing the right tank.

Types of Sedimentation Units

Plants use more than one kind of clarifier. Each type meets a specific need. Let us have a look at some

Primary Clarifiers: Primary clarifiers remove heavy solids first. Raw wastewater flows in. It slows in a wide tank. Solids settle and form sludge on the floor. The clear water exits for the next phase.

Secondary Clarifiers: Secondary clarifiers follow biological treatment. They remove biomass and fine particles. Treated water enters from the top. It flows gently down. Biomass settles and forms a layer. A small portion returns to the bioreactor. The rest goes on to disinfection.

Design Considerations for Clarifiers

A well designed clarifier boosts removal efficiency. Each factor links to plant goals. Let us have a look at some

Surface Loading Rate: This rate shows how much water flows per square meter of tank area. A lower rate gives more time for particles to fall. Designers set this rate to balance land use and performance.

Detention Time: This is the time water spends in the tank. Longer time helps fine particles settle. Too short a time leaves solids in water. Too long a time means larger tanks and more cost.

Good design pairs these factors for steady performance. Next we study the factors that affect settling efficiency.

Factors Affecting Settling Efficiency

Settling works best under ideal conditions. Changes in those conditions can slow the process. Let us have a look at some

Particle Size and Density: Larger denser particles sink faster. Smaller lighter ones take more time or may not settle at all. Pretreatment steps can help by clumping fine solids together.

Flow Conditions: Steady flow keeps particles in a layer above the tank floor. Sudden surges or short circuits can push solids out with the flow. Baffles and inlet design help maintain uniform flow.

Awareness of these factors leads to more reliable clarifier performance. Finally we cover maintenance and operation.

Maintenance and Operation of Sedimentation Units

Proper care keeps sedimentation units running well. Regular tasks prevent failures and maintain output. Let us have a look at some

Regular Inspection: Operators check for wear and tear. They look at scrapers and baffle walls. They note any leaks or blockages. Early fixes avoid downtime.

Sludge Removal: Settled solids build up on the tank floor. Regular removal stops sludge from rising back into the water. Many plants use scraper mechanisms to guide sludge to hoppers. The sludge then moves on to thickening or dewatering steps.

Following these steps keeps the sedimentation stage effective and long lasting.

Conclusion

Netsol Water stands out as a leading sewage treatment plant manufacturer that include expert design of sedimentation in sewage treatment plants. Understanding how solids settle and how to design and run clarifiers helps plants meet discharge standards. Our team can guide you through each step. Contact us today for more information or to request a consultation. Trust Netsol Water for reliable performance in sedimentation in sewage treatment plants.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com