Introduction

An oil water separator performs exactly what its name implies:

It separates oil and suspended solids from water, allowing it to be skimmed away.

Since oil is lighter than water, it floats to the top. However, due to the nature of wastewater, which is contaminated with a variety of impurities, certain oil particulates, particularly microscopic droplets, can become clogged.

Heavy solids (sludge) settle to the bottom of oil water separators, while oil gets to the surface, leaving extra wastewater in the middle layer. The sludge can then be swept away, the oil can be skimmed off the top, and the wastewater can proceed to the next step in the treatment process.

Is oil removal a part of waste water treatment?

It's not easy to separate water and oil into two distinct entities in the waste water treatment sector. Oil removal from wastewater during processing, in fact, necessitates the employment of specialised equipment.

Oil water separators are a part of waste water treatment, and they're used in conjunction with a range of physical, chemical, and biological filtration techniques to segregate waste from water so that clean water may be returned to the environment. Depending on the industry, multiple methods for extracting waste materials from effluent may exist.

While dissolved air flotation (DAF water treatment) is regularly utilised in the industrial wastewater treatment business, dissolved gas flotation (DGF water treatment) is more generally used in the oil industry. Regardless of whether the wastewater originates from homes, businesses, or industries, it must all be processed in order for waste to be eliminated and clean water to be rescued.

Isn't it true that oil separates from water on its own?

True, there is a gravitational difference between oil and water.

Because oil is lighter than water, it floats to the top. However, due to the nature of wastewater, which is contaminated with a variety of impurities, certain oil particulates, particularly microscopic droplets, can become clogged.

Heavy solids (sludge) settle to the bottom of oil water separators, while oil gets to the surface, leaving extra wastewater in the middle layer. Depending on the water being treated, sludge can be brushed away, oil can be skimmed off the top, and wastewater can be moved forward for additional filtering, aeration, DAF water treatment, and chemical processing.

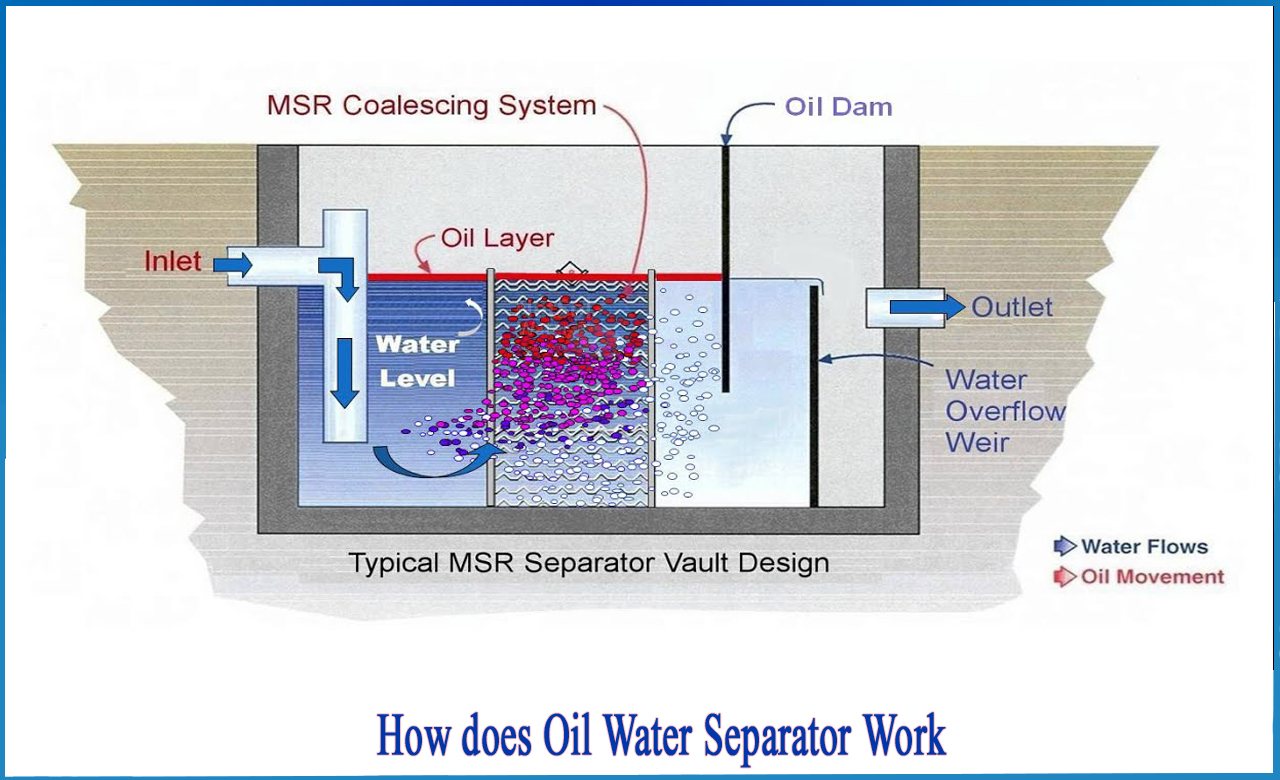

How does oil water separator work?

>Wastewater is injected into an oil water separator for treatment after passing through filters to remove the largest solids. Wastewater is usually pumped through a series of plates that are positioned on an inclination.

>These plates segregate oil, water, and sludge into three distinct zones. The heavier filth and suspended particles descend to the bottom. The plates, on the other hand, provide a particular purpose since oil particulates might be fairly small.

>When wastewater flows over the plates, oil particulates are thrown across the surface, allowing them to aggregate and form larger globules, increasing buoyancy. As a result, more oil splits from the water and rises to the top.

The stacked plates increase the amount of surface area that wastewater must travel over, and their slope serves to drive the oil up to surfaces where it can condense and create larger particles. Before wastewater is sent to finer filtration procedures, the oil water separator guarantees that the great majority of oil and sludge is eliminated.

Why does oil need to be separated from water?

Cooking oils and grease, which are washed down the drain in homes, restaurants, and other business establishments, could be detected in wastewater, as well as petroleum and other dangerous materials. These have the potential to destabilise ecological processes and harm plants, animals, and even humans.

If users have ever watched television coverage of an oil spill, user should be aware of the devastation that oil can create, even if they were massive tragedies. But don't be fooled into thinking that oil in wastewater is any less harmful.

It can certainly hurt the environment if it can clog the pipes. This is why oil water separators are so vital for separating it from wastewater and disposing it off.

Therefore, user should install the best waste water treatment which has oil water separator as well.

For the best waste water treatment and best services, contact Netsol water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.