What is dissolved air flotation?

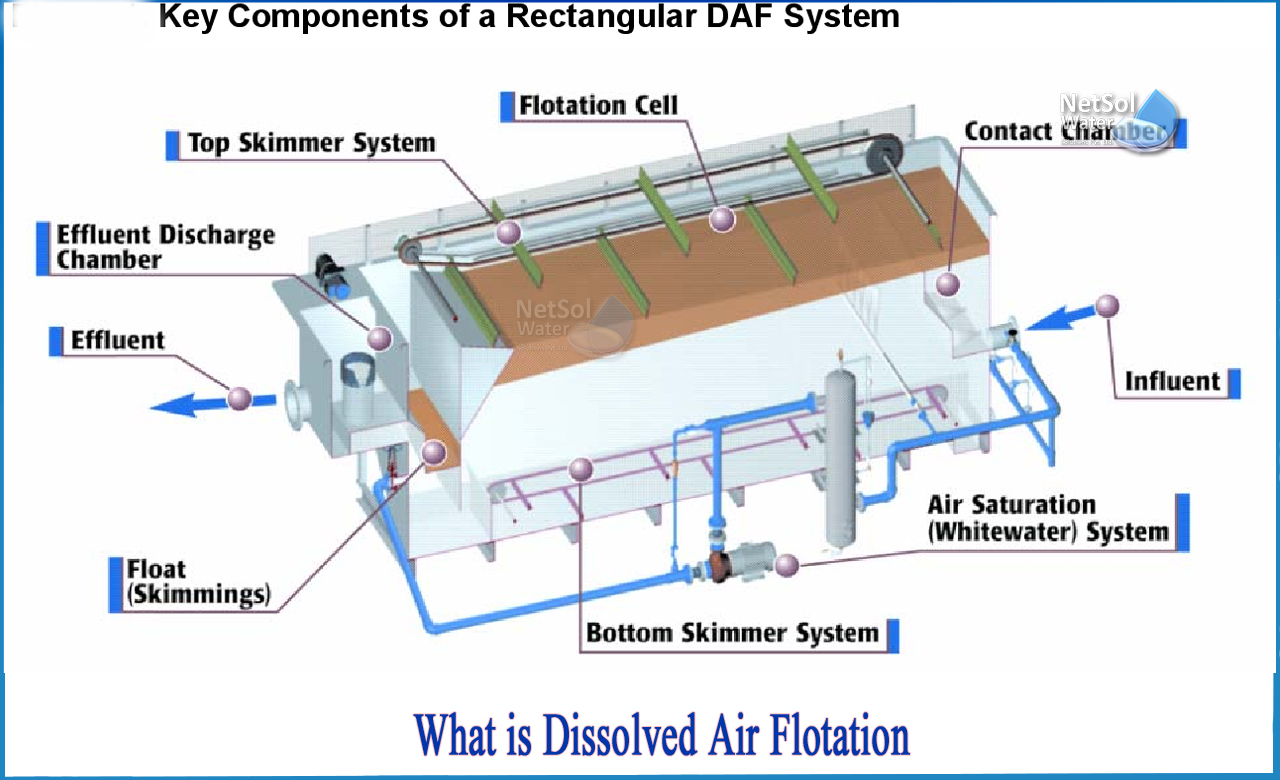

DAF is a water treatment process that clarifies wastewaters (or other waters) by removing suspended matter such as oil or solids. The air is removed by dissolving it under pressure in the water or wastewater and then releasing it at atmospheric pressure in a flotation tank basin. The released air creates tiny bubbles that adhere to the suspended matter, causing it to float to the surface of the water and be removed by a skimming device.

Dissolved air flotation is commonly used in the treatment of industrial wastewater effluents from petrochemical, oil refineries and chemical plants, general water treatment plants, natural gas processing plants, paper mills, and other similar industrial facilities. For wastewater treatment, a process known as induced gas flotation is used. In the processing of mineral ores, froth flotation is commonly used.

Advantages of dissolved air floatation:

- Reduced footprint – In comparison to any comparable system with comparable flow rate/loading levels.

- High efficiency – Makes use of inclined settling tubes to increase surface area and speed up separation.

- Air sourcing – used to clean tubes automatically.

- Whitewater pumps– Rugged pumps combined with saturation tanks provide industry-leading reliability and low maintenance whitewater (dissolved air).

- Countercurrent scraping– the most efficient method of separating sludge from effluent water. Additionally, more free water can be decanted prior to sludge removal.

- Sludge grating/thickening– Prevents and thickens sludge migration.

- Fewer moving parts– no bottom auger or motor required.

- Full movable skid– An optional skid with winch attachment.

Process of dissolved air floatation:

The feed water to the DAF float tank is frequently (but not always) supplemented with a coagulant (such as ferric chloride or aluminium sulphate) to coagulate the colloidal particles and/or a flocculant to conglomerate the particles into larger clusters.

A portion of the clarified effluent water leaving the DAF tank is pumped into a small pressure vessel (referred to as the air drum) along with compressed air. As a result, the pressurised effluent water is saturated with air. The air-saturated water stream is recycled to the front of the float tank and flows through a pressure reduction valve just as it enters, resulting in the release of air in the form of tiny bubbles.

Bubbles form at nucleation species on the surface of suspended particles and adhere to them. The lift from the bubbles eventually overcomes the force of gravity as more bubbles form. The suspended matter floats to the surface, where it forms a froth layer that is then removed by a skimmer.

The clarified effluent from the DAF unit exits the float tank as froth-free water.Some DAF unit designs use parallel plate packing material (e.g., lamellas) to provide more separation surface and thus improve the unit's separation efficiency.

DAF systems are divided into two types: circular (more efficient) and rectangular (more residence time). The former type takes only 3 minutes. A specific circular DAF system is known as a "Zero speed" system because it allows for quiet water status and high performance; a typical example is a 2K DAF system. The rectangular type takes 20 to 30 minutes to complete. The spiral scoop is among the most significant advantages of the circular type.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.