How Do You Calculate HRT in a Sewage Treatment Plant?

Hydraulic Retention Time influences many stages of sewage treatment. It helps to ensure that the wastewater remains long enough for biological and physical processes to occur. An accurate calculation supports consistent effluent quality. It also helps to size tanks and choose equipment. Netsol Water applies advanced design methods to make this process straightforward. Netsol Water equips managers and engineers with the tools they need to achieve efficient treatment.

What is Hydraulic Retention Time?

Hydraulic Retention Time refers to the average time that sewage stays in a treatment unit. It offers a measure of contact time between wastewater and treatment media. Engineers use this metric to predict treatment performance. Let us have a look at some core aspects.

Average Volume of Reactor

You calculate this by finding the total liquid volume in the reactor. You include the working volume only. Any dead zones do not count in this figure.

Influent Flow Rate

You measure the flow rate at the inlet. You use consistent units such as cubic meters per hour. You must record this rate over a representative period. These two values link directly to compute the Hydraulic Retention Time.

Read: Sewage Treatment Plant Manufacturer

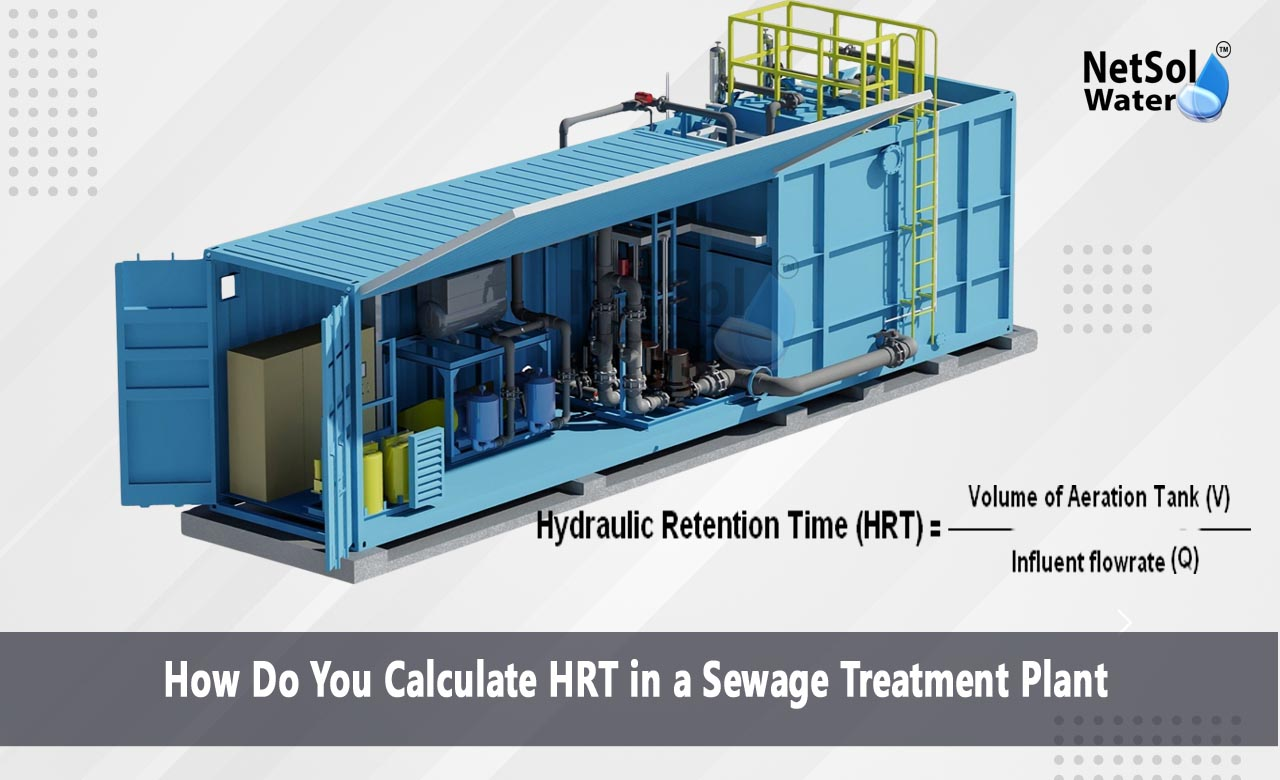

Formula to Calculate Hydraulic Retention Time

Understanding the formula plays a key role in design accuracy. The formula shows how volume and flow interact. Let us have a look at some key formulas.

Basic HRT Formula

Divide the reactor volume by the influent flow rate. This yields time units. You may express results in hours or days.

Unit Conversion Details

Check that volume units match flow units before dividing. Convert liters to cubic meters or vice versa as needed. Convert minutes to hours for flow rates recorded in minutes.

These steps help to avoid errors and to apply the formula directly in design.

Factors Affecting Hydraulic Retention Time

Many factors influence the ideal HRT for a given system. You must account for temperature and organic load. These variables change treatment kinetics. Understanding them supports smarter design choices. Let us have a look at some critical factors.

Temperature Impact

Microbial activity slows in cold conditions. Higher temperature boosts reaction rates. These changes shift the required retention time for effective treatment.

Organic Load Considerations

High organic concentrations demand longer retention time. Low concentrations may allow lower HRT. You test the influent to determine the precise load. By adjusting HRT for these factors you secure stable treatment even under variable conditions.

Example Calculation of Hydraulic Retention Time

A worked example can clarify the entire process. You follow each step to ensure no detail is overlooked. Let us have a look at some sample data.

Sample Data

The reactor holds eight hundred cubic meters of mixed liquor. The influent flow rate stands at one hundred cubic meters per hour.

Calculation Steps

First you confirm that units match. The volume reads in cubic meters and the flow reads in cubic meters per hour. Next you divide eight hundred by one hundred. The result equals eight hours.

This example shows that the sewage remains in the reactor for eight hours on average.

Conclusion

Hydraulic Retention Time remains a key design and performance measure in sewage treatment. Netsol Water leads as a manufacturer that guides every step of this calculation. We help clients apply accurate HRT calculations for improved effluent quality. You can trust our team to deliver practical solutions that meet regulatory standards.

Contact Netsol Water for more information or to request a consultation on Hydraulic Retention Time calculations in your treatment plant.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com