The water treatment plant must use a specific water treatment procedure to remove suspended solids, colloids, and dissolved contaminants from the raw water, in order to serve as the first station to supply us with safe drinking water. Its significance is obvious given that it meets the needs of both industrial production and home drinking water needs.

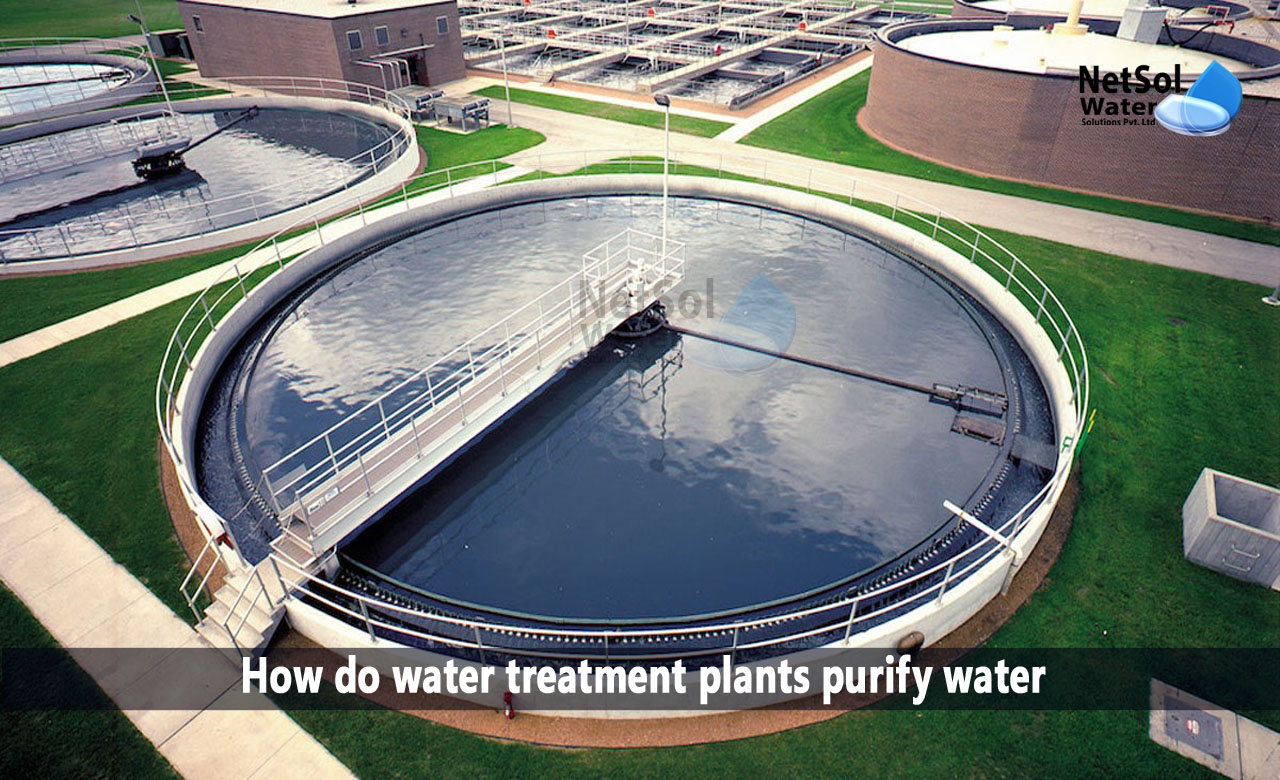

How do water treatment plants purify water?

The water treatment plant's procedure for treating water includes fresh water mixing, flocculation and sedimentation, filtration, disinfection, use of RO Plants, and a clean water reservoir.

1. Blending/Mixing

The addition of the chemical must be followed by a short mixing operation. The goal of mixing is to swiftly and equally distribute the chemical in the water, by hydraulic and mechanical agitation.

Currently, mixing is typically done using a water pump, a tube static mixer, a mechanical mixer, or drops of water. The mixing period typically lasts between 10 and 60 seconds, and the stirring period typically lasts between 600 and 1000 seconds. After mixing and flocculating, the connected pipe has a flow rate of 0.8–1.0 m/s.

2. Sedimentation and Flocculation

Good hydraulic conditions and enough flocculation time are necessary for the flocculation process. Mechanical flocculation, folding plate flocculation, grid flocculation, and other types of flocculation are frequently utilized.

The flocculated water flows into the sedimentation tank after mixing. The water's particles descend to the bottom of the tank as a result of gravity. To maintain an even water flow in and out of the tank, a stable water flow, and to increase the sedimentation efficiency as much as possible, there must be enough sedimentation time during the sedimentation process.

3. Filtration

Pre-filtration treatment typically uses a sand tank filled with quartz and filter material. A portion of the suspended material in the water is captured by adhesion, in the quartz sand filter material layer in the sand tank.

To further filter out small suspended pollutants, organic waste, germs, and viruses in the water, employ RO plants, sediment filters, UV rays, etc., for more precise filtering.

4. Disinfection

Following filtration, the water's turbidity is further reduced, and at the same time, any remaining bacteria and viruses are freed from the turbidity's protection or adhesion, which improves the circumstances for disinfection.

Although, most bacteria and viruses can be eliminated from water by coagulation, precipitation, and filtering, a disinfection process is necessary to obtain the bacteriological index required for drinking water. At the end of the city water pipe, it keeps a little amount of residual chlorine to control bacterial growth and avoid contamination.

How can we assist our clients in achieving high drinking water treatment requirements?

To effectively produce high-quality drinking water, Netsol Water provide a wide range of water treatment technologies. Aeration, filtration, softening, disinfection, and the elimination of micro-contaminants may be included in the treatment train, to

· Meet drinking water standards.

· Clean up the drinking water in sensitive metropolitan areas and beneath buildings.

· Eliminate contamination in the hotspot/source zone.

· Eliminate contaminants that have spread widely.

· Avoid soil contamination by avoiding excavation, disposal, and any other interaction.

· Give you a realistic assessment of the outcomes that are possible.

Get your water purification systems from experts!

Netsol Water provides design and manufacturing services to create a unique water treatment plant. Whether you require a water treatment plant for commercial or industrial use, we will assist you in selecting the best solution as per your need and requirement.

Contact us right now to find out more about our water treatment products and services. All kinds of chemical, physical, and biological impurities can be effectively eliminated, by our water treatment systems. For further information or to make a product purchase, contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com