What is Aeration?

Aeration is a crucial phase in the treatment of wastewater, which includes sewage effluent.It is the process of bringing water and air together to remove dissolved gases and oxidize dissolved metals such as iron, hydrogen sulphide, and volatile organic compounds (VOCs). This occurs during the secondary treatment operations of activated sludge treatment in wastewater treatment facilities, and it is frequently the first substantial step in a drinking water treatment facility. An aeration system with an appropriate distribution of oxygen supply is critical for optimal wastewater treatment and microbiological development in ETPs.

Types of aeration:

1. Fine bubble diffusers;

2. Coarse bubble diffusers;

3. Surface aeration;

4. Packed tower aerators.

Applicability of Aeration Systems

Aeration is an essential element of the secondary treatment process in municipal and industrial wastewater treatment. For the secondary treatment in ETPs, aeration of wastewater is done to enhance the quality and minimize contamination in liquids and foods. In this process, soluble iron and manganese are oxidized to insoluble precipitates. Aeration can also help with bacteria management by reducing ammonia and hydrogen sulphide levels.

Aeration treatment process is applicable to the following situations:

1. MIW discharge with high amounts of dissolved metals and low natural dissolved oxygen;

2. A large number of locations that are ideal for active treatment methods;

3. The ability to handle a wide range of flow conditions;

4. Combination with other metals and neutralizing technologies.

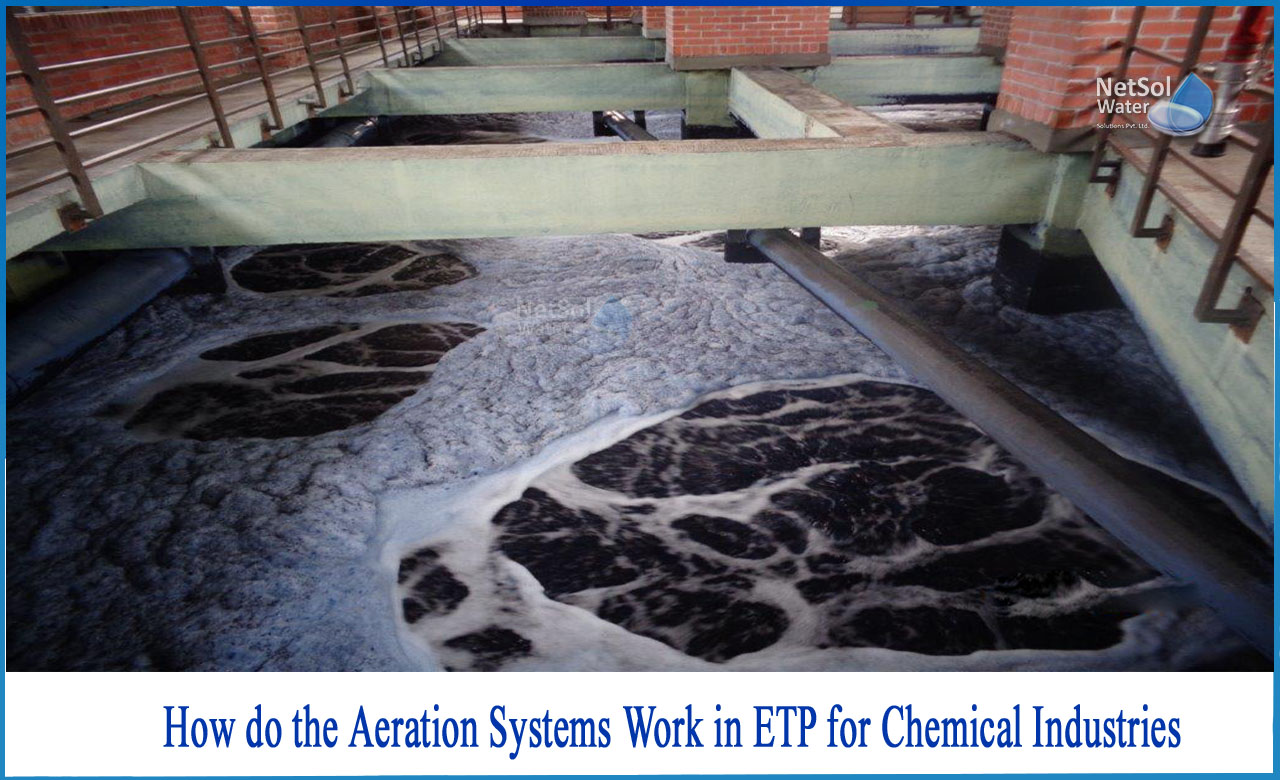

How do the Aeration Systems work in ETP for Chemical Industries?

The treatment of wastewater is an important element of the chemical production process. It's vital that chemical wastewater get the proper treatment.

For the biodegradation process to take place, the bacteria in the water require oxygen. Because bacteria require oxygen to clean and stabilize wastewater, aeration is beneficial. Using the oxygen provided, bacteria in the wastewater break down organic debris containing carbon to produce carbon dioxide and water. Bacteria can't biodegrade incoming organic stuff in a suitable amount of time if they don't have enough oxygen.

In the lack of dissolved oxygen, degradation must take place under septic conditions, which are slow, smelly, and result in incomplete pollutant transformations. Some biological processes under septic conditions convert hydrogen and sulphur to generate hydrogen sulphide and carbon to methane.Other carbon will be converted to organic acids, lowering the pH of the water in the basin, making treatment more difficult and boosting odour formation. In the absence of oxygen, organic matter biodegradation is an extremely sluggish biological process.

There are two common methods for aeration: surface mounted aerators and fine bubble diffusers.

Aerators located on the surface agitate the effluent at high speeds, dragging wastewater from the bottom of the tank to the top and mixing it with air.

Fine bubble diffusers are the most common alternative to surface mounted aerators. These diffusers are installed at the bottom of the tank and produce delicate bubbles that rise upward. As they ascend, the bubbles disperse into the wastewater, providing the oxygen required for aeration.

How can Netsol Water help?

We are one of the leading water and wastewatertreatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing. We can customize wastewater treatment solutions for a wide range of industries including chemical industries.