How can you improve the Circular Secondary Clarifiers?

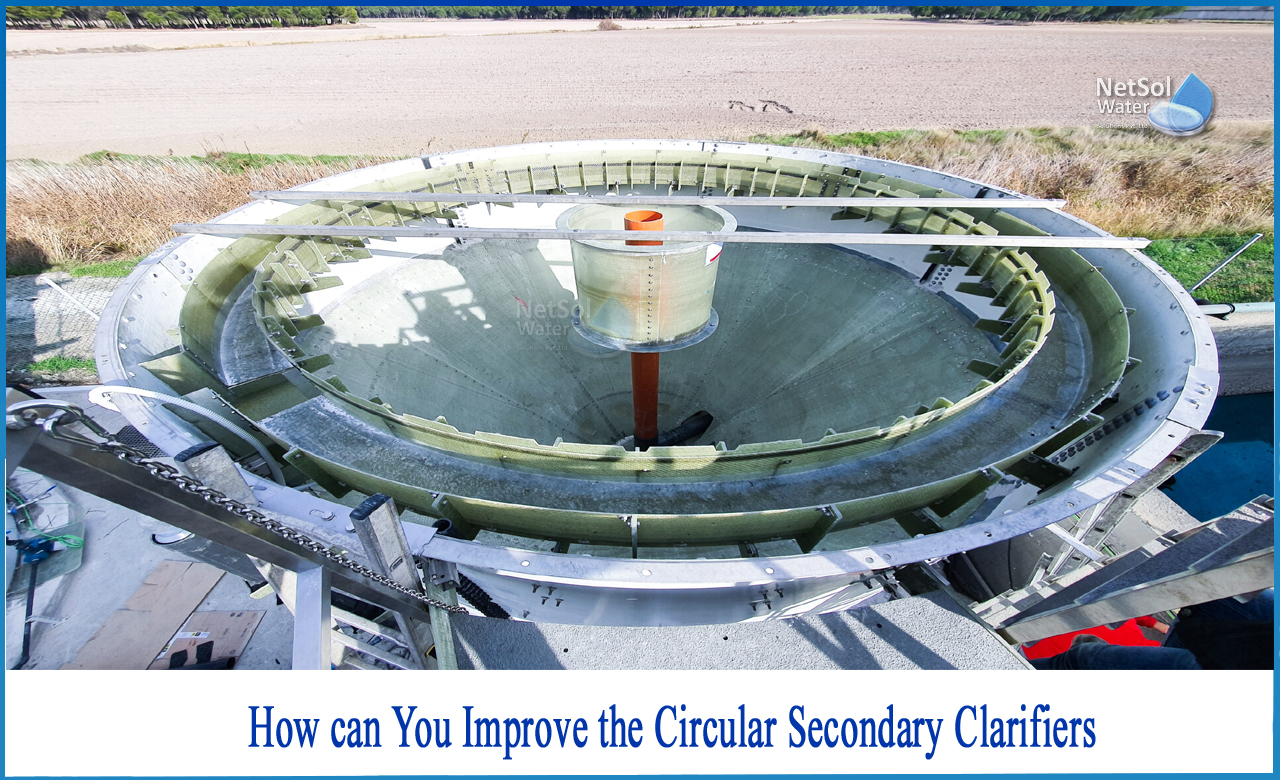

Circular clarifiers are used to remove suspended particles from liquids and are widely employed in the wastewater and water treatment sectors, as well as in mining, reverse osmosis, and paper and pulp mills.

Sedimentation is a procedure that includes the use of clarifiers-

The process of sedimentation is the separation of suspended particulates from a liquid. Sedimentation basins or settling tanks are utilized when sedimentation is caused only by gravity. Clarifiers are machines or equipment’s that use mechanical means to accomplish the sedimentation process.

Improvisation of the circular secondary clarifiers

Traditional secondary clarifiers do not account for hydraulic energy dissipation. These are either overly big or frequently fail to provide efficient solids-liquid separation.

Recent technological advancements have resulted in a clarifier design that is vastly different from traditional circular clarifiers. It is a high-rate secondary clarifier with solids contact and sludge recirculation that offers natural flocculation through plume development and effectively dissipates hydraulic energy. It provides high effluent quality and assists in achieving treated effluent quality that meets discharge criteria, with settled sludge being removed by a specifically built suction mechanism.

To overcome the disadvantages of traditional clarifiers, new circular secondary clarifiers are designed.

Natural flocculation happens as a result of hydraulic energy dissipation and the production of a sludge cloud known as a plume in the new clarifier.

The effectiveness of the clarifier is determined by the plume's stability, which is determined by the velocity gradient. A velocity gradient of 10 to 15 s is found to be advantageous for spontaneous flocculation. The plume rise is likewise kept considerably below the free-surface at this velocity. In the plume, the mean particle size of mixed liquid suspended solids rises from 41 to 83 micron, indicating particle agglomeration and confirming that natural flocculation is occurring.

Hydraulic energy is dissipated, flow is consistently distributed, sludge blanket disturbances are minimized, and flocculation is promoted as a result of improved intake design. The upgraded clarifier has a hydraulic retention time of one hour.

Important Characteristics of circular secondary clarifiers

1: Hydrodynamics- To guarantee natural flocculation, optimize the velocity gradient and hydraulic energy dissipation.

2: Geometry- Providing a better intake design and bottom to optimize solids handling.

3: Sludge Removal Mechanism- A better sludge removal suction mechanism is being developed to remove the settled sludge.Separates liquids and makes sludge removal easier.

Advantagesof circular secondary clarifiers

1: Improved solids-liquid separation guarantees that the treated effluent has the smallest amount of suspended solids (SS).

2: A high concentration of underflow solids reduces pumping rate while maintaining the optimum active biomass content in the aeration tank.

3: It requires reduced surface area and works at a short hydraulic retention time (1.5–2.0 hours HRT), allowing for capital cost reductions.

4: It eliminates the need for a separate sump cum pump house for sludge recycling and removal, saving both capital and operating expenditures.

5: It delivers natural flocculation and eliminates the need for a separate flocculation facility, lowering both capital and ongoing costs.

6: For the Final Draft, the design is verified using computational fluid dynamics tests.

Why should you chose us for wastewater Treatment?

Netsol Water, based in Greater Noida, India, is a well-known industrial and commercial water and wastewater treatment plant manufacturer. We provide experienced treatment solutions for all of your needs. In accordance with industry standards, our treatment plants employ top quality raw materials and the most up-to-date equipment’s.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.