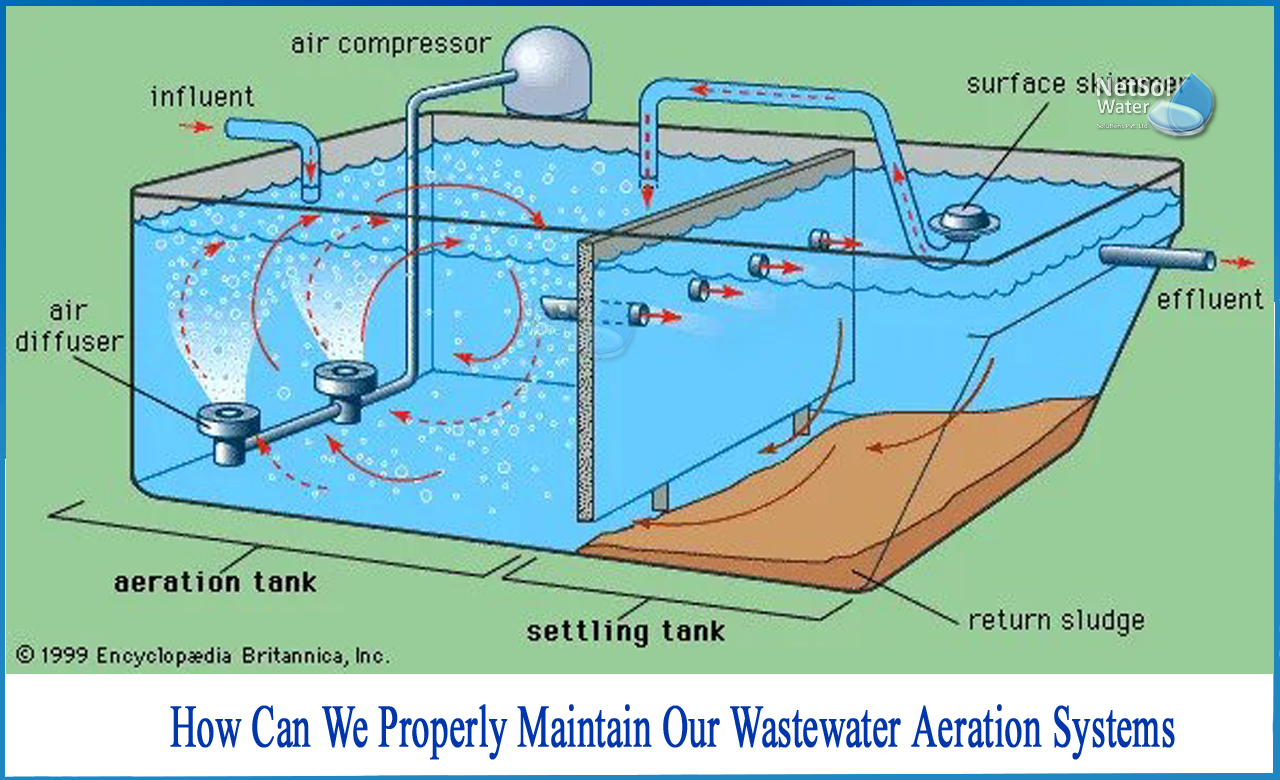

How can we properly maintain our wastewater Aeration systems?

Wastewater aeration systems require regular maintenance. A piece of wastewater treatment equipment's operating life can be reduced by as much as 30% if it is not properly maintained. For some long-lasting equipment, the difference equates to a loss of years of service.

Why is it important to keep wastewater treatment systems in a good condition?

For a variety of reasons, wastewater treatment systems must be maintained. As a result, you'll be able for following:

1: Extending the life of your wastewater treatment system: Maintaining your wastewater treatment system will help you get the most out of it. Diffusers, pipelines, and blowers can all benefit from routine maintenance.

2: Increasing aeration efficiency: Maintaining your system on a regular basis can help you achieve high oxygen transfer rates and aeration efficiency. These levels might plunge if you ignore the maintenance your device requires.

3: Reducing energy consumption: A well-maintained wastewater treatment system would help your facility reduce the energy consumption. A system that undergoes regular maintenance will put less strain on its blowers and use less electricity.

4: Cost-cutting: Wastewater treatment equipment is expensive. According to the United States Environmental Protection Agency, wastewater collection and treatment systems account for around 15% of all infrastructure value in the country, or $1 to $2 trillion in total. Repair or replacement expenses for components that wear out due to infrequent maintenance can soon build up. Plant utility prices skyrocket as demand for electricity rises.

5: Increasing the efficiency of a facility: A well-maintained wastewater treatment system performs better overall. It has more dependable equipment, delivers greater aeration, and keeps a tighter grip on its energy use and budget.

Maintenance guidelines for wastewater treatment systems

An effluent treatment plant maintenance checklist and some wastewater aeration system maintenance guidelines are provided below:

1: Maintain a thorough schedule: Make a schedule for the maintenance your plant will require, and adhere to it. Maintaining equipment that seems to be in excellent working order is far easier and less expensive than making more difficult repairs or replacements for equipment that has failed.

2: Make a to-do list: It's easy to overlook something minor but critical when a company has so much equipment. Making a wastewater treatment plant maintenance to-do list will guarantee that each piece of equipment receives the attention it needs, to remain operational.

3: Make the necessary changes: As required, make adjustments to your maintenance strategy. More regular maintenance may be required if you discover that your plant is processing more volume or that your wastewater includes a higher concentration of solids.

4: Examine for symptoms of ageing: Over time, submerged equipment may show indications of age. Rubber may shrink, stiffen, or stretch, while plastic may become brittle and fracture. Make careful to replace these parts before they have an impact on your system's performance.

What can happen if your wastewater treatment system is not maintained?

It may appear to be OK to put off maintenance for a day, then a few more days.

Unfortunately, that extra time adds up rapidly, and failing to maintain your wastewater treatment system can result in a variety of issues, including: Reduced aeration efficiency, decreased diffuser and blower lifespan, increased backpressure, etc.

Conclusion

Netsol Water is a global leader in excellent solutions and service. Our products provide cutting-edge designs, cutting-edge engineering, and time-tested quality to keep wastewater treatment systems running smoothly.

Contact the water treatment experts at Netsol Water to discover more about why we're trusted and appreciated all across the world.