How are Stabilization Ponds constructed?

The use of stabilization ponds for wastewater treatment is contingent on the purchase of a collecting system. Sewerage systems are not prevalent in poor nations’ metropolitan areas, and they aren't always the best sanitation technology, but if collection is warranted, stabilization ponds will be the treatment method of choice. The exceptions will be in areas with karst geology, with very permeable strata and where land costs (or opportunity costs) are extremely high.

Details of the construction for Stabilization Ponds

It is necessary to adapt the process design for stabilization pond systems into a physical design. Actual pond dimensions must be chosen, embankments and pond inlet/outlet structures must be planned, and decisions on preliminary treatment, pond liner, piping, fencing, and other issues must be made.

Preliminary Wastewater Treatment Systems for Stabilization Ponds

Prior to treatment in ponds, units such as screening and/or grit removal are occasionally supplied.

If maintenance can be ensured, a manually raked bar screen is all that is required in small pond systems (serving less than 2000 people). Otherwise, raw sewage should be introduced into the primary pond. Mechanically raked screens and mechanical grit separators may be utilized for bigger populations, although they are the most susceptible portions of the system if maintenance is a concern. The design of such preparatory treatment facilities should adhere to accepted industry standards. It is necessary to provide enough provisions for the disposal of screenings.

If the sewer system is not of the separate type, there should be a storm water overflow and a Parshall to monitor wastewater flow immediately after preparatory treatment, if any. Automatic flow recorders are recommended for high flows but are too inconvenient for small ponds. Because pond performance cannot be examined without one, a flow measurement equipment is required.

Geometry of the Stabilization ponds

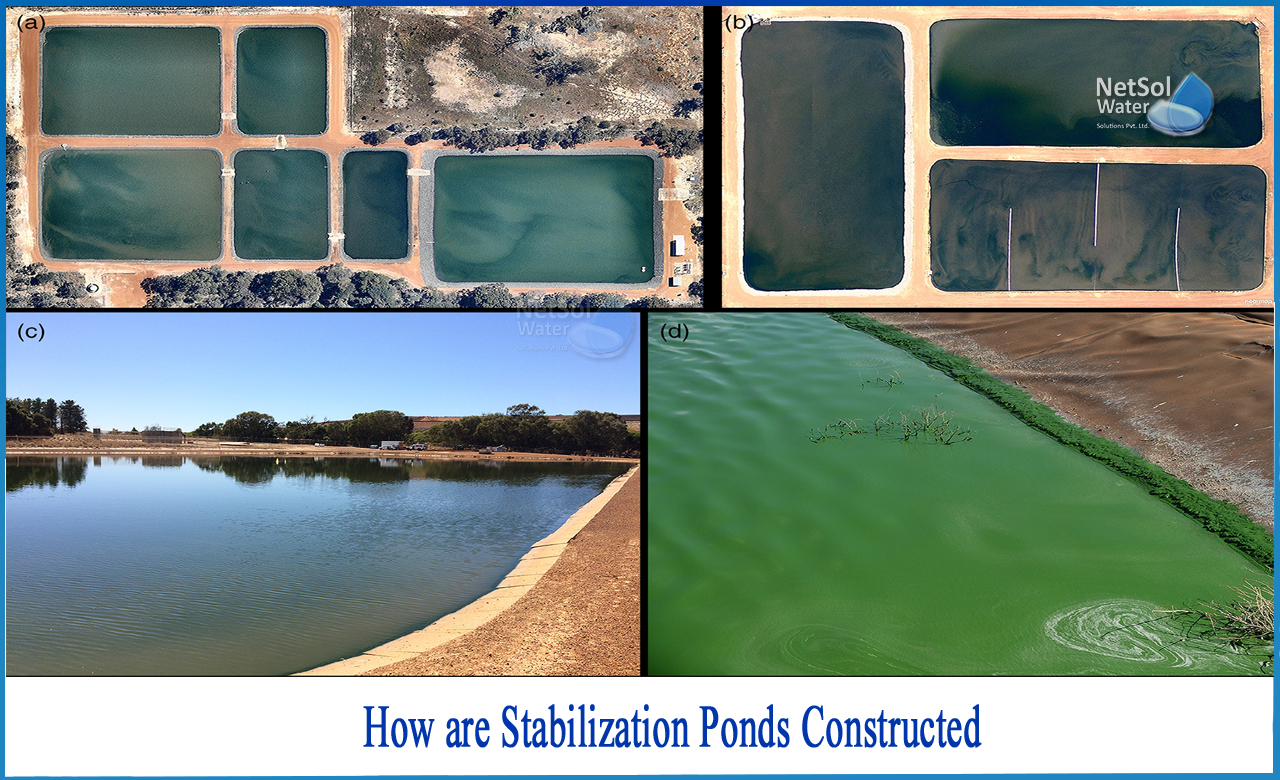

There hasn't been much research towards finding the best pond form. The most frequent form is rectangular, however the length-to-breadth ratio varies greatly. Clearly, the best pond geometry, which incorporates not only the pond's form but also the relative placements of the inlet and exit, will reduce hydraulic short circuiting.

Rectangular Waste Stabilization Ponds

In order to minimize sludge banks accumulating near the inlet, anaerobic and primary facultative ponds should be rectangular with a length-to-breadth ratio of less than 3. Wherever feasible, secondary facultative and maturation ponds should have larger length-to-breadth ratios (up to 20:1) to better resemble plug flow conditions; high length-to-breadth ratios can also be accomplished by including baffles into the pond.

Ponds don't have to be perfect rectangles; they can be softly curved if required or aesthetically pleasing. In most cases, a single inlet and exit are adequate, and they should be placed in the pond's diagonally opposed corners. To enhance wind-induced mixing, the pond should be situated so that its longest dimension (diagonal) is in the direction of the wind.

Effect of wind on Waste Stabilization Ponds

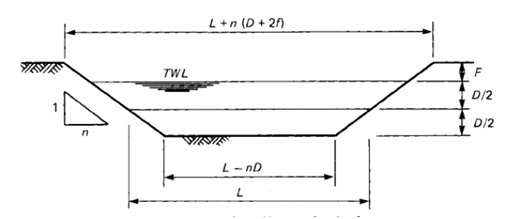

If the wind direction varies throughout the year, the summer wind direction should be chosen because this is when thermal stratification is most likely to occur. The intake should be placed such that wastewater flows into the pond against the prevailing wind to avoid hydraulic short-circuiting. Process design processes compute mid-depth regions, and the dimensions derived from them are also mid-depth dimensions. These must be adjusted for the embankment's slope. The contractor has to know the dimensions and levels of the base and top of the embankment; the latter includes the influence of the freeboard (F).

The minimal amount of freeboard that should be given is determined by the need to prevent wind-induced waves from overtopping the embankment. Freeboard should be provided for small ponds of 0.5 m; for ponds of 1 to 3 ha, the freeboard should be 0.5-1 m, depending on site factors.

The freeboard may be estimated using the calculation for bigger ponds as:

Where, F = freeboard, m

A = pond area, m2

Pond liquid depth: Depth of liquid in Waste Stabilization Ponds

Anaerobic ponds 2-5 m

Facultative ponds 1-2 m

Maturation ponds 1-2 m

The depth of each given pond is determined by site considerations (presence of shallow rock, minimization of earthworks). It is advantageous to provide a deeper zone (2-5 m) near the inlet for sludge settlement and digestion in primary facultative ponds, especially those with high length-to-breadth ratios. This isuseful in systems treating wastewater with a high grit load when no grit removal facilities are included.

It is recommended to have two or more series of ponds in parallel for any pond installation, but notably for pond systems handling flows in excess of roughly 500 m3/day, in order to enhance operating flexibility.

Operation and maintenance of Waste Stabilization Ponds

The services supplied to pond operators will vary depending on their quantity, but they should typically comprise the following:

• A first-aid kit is required.

• Lifebuoys strategically positioned.

• Toilet and washbasin

•Storage room for personal protection equipment, scum-removal equipment, grass-cutting, a screen rake and other tools.

Except for the lifebuoys, these may all be housed in a basic (for example, timber) structure. If necessary, sample bottles and a refrigerator for sample storage can be stored here as well. Such capabilities are not usually provided for small systems, but they should be present in the service van. At bigger establishments, basic laboratory facilities and a phone should be available. There must also be sufficient parking space.

Pond care is straightforward, but it must be done on a regular basis to avoid stench, fly, and mosquito problems.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems by strategically integrating modern treatment technology with practical solutions. We are the leading name for manufacturers of water and wastewater treatment plants including Stabilization Ponds, and are known to be NO. 1 at solving complicated processes of water and wastewater.

If you need any technical help and guidance, or simply have a query regarding our water or wastewater treatment technology solutions, contact one of our expert advisers via phone at +91 9650608473