How to get ultra pure water for industry?

Extra pure water or ultrapure water (UPW) or highly purified water(HPW) is water which has been purified to uncommonly precise specifications. This term that is Ultrapure water is a term that is used in semiconductor industry to stress on a fact that the water is purified and treated with the highest levels of purity for all contaminant types that includes organic and inorganic compounds or dissolved and undissolved or reactive and inert or hydrophilic and hydrophobic or dissolved gases.

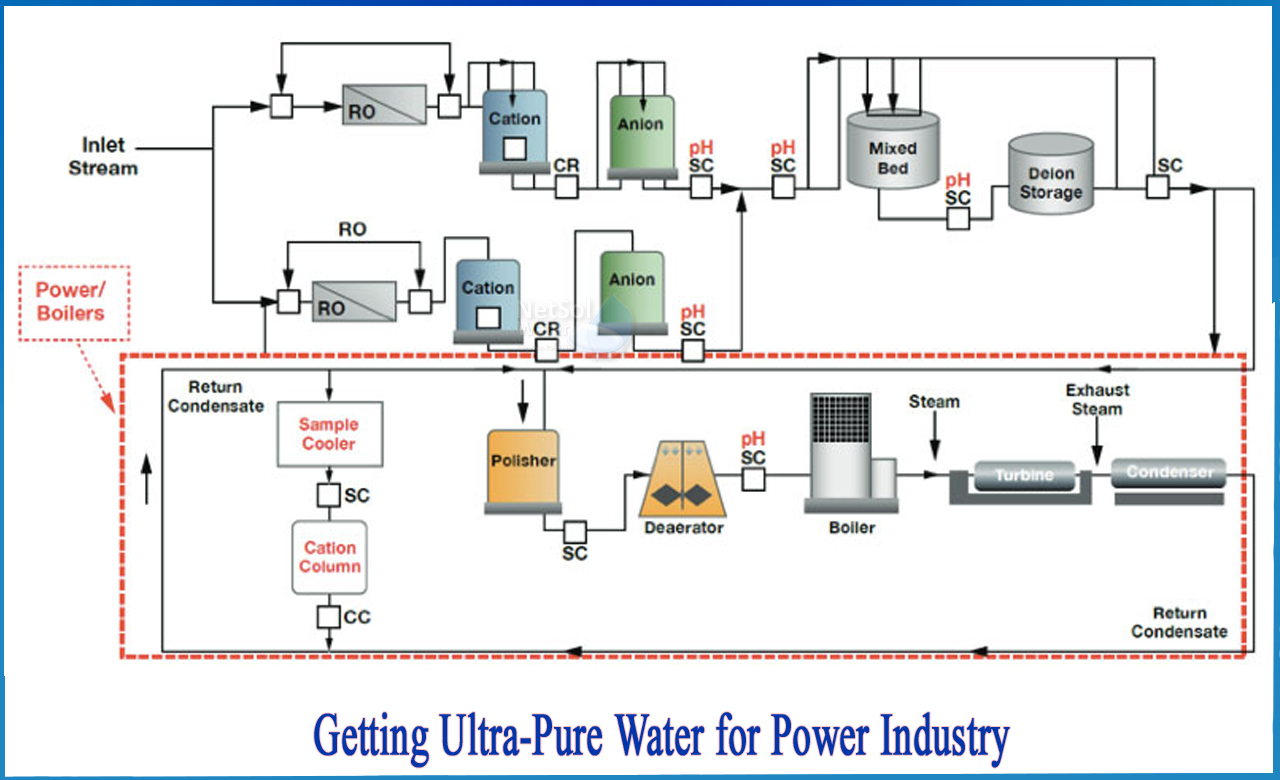

UPW system has three stages:

The first stage that is a pretreatment stage that produces purified water.

The second stage or the primary stage later on purify the water more.

The third stage or the polishing stage is the most expensive part of this treatment process.

In most cases, water is salty but that's completely fine for power generation. Sometimes water that has been treated for human consumption may still have some microscopic impurities which is only visible through a microscope and not by naked eyes. Ultrapure water is the water that has been treated to the strictest possible standards.

The ultrapure water process starts with pretreatment, and this is done by a reverse osmosis water filter (RO), activated carbon water filter, or UV purification, prior to employing a deionizing water system of ion exchange or electro-deionization (EDI).

WATER PURIFICATION SYSTEM:

This water purification step that is the first step allows the user to take potable water and turn it ultrapure in a four-piece system. It first gives pure grade water from the tap through use of an EDI system, mixed with a pretreatment regimen of RO and bactericidal UV. A polythene tank is used to store this pure water to protect it from any airbornecontaminants. The water is then passed through a dual wavelength UV lamp and after that through a polishing cartridge that removes any organic contaminants.

CONATAINERIZED ULTRAPURE WATER SYSTEMS:

This step includes pre-filtration with alum dosing and pre-chlorination; activated carbon filtration; chemical pre-treatment with pH adjustment and anti-scalant dosing; cartridge filtration; first and second pass RO; gas transfer membranes; and lastly EDI.

The last step includes a nanotechnology coated mesh that activates five photochemical processes to get purified water.

These types of power plants, which is also known as thermoelectric or “thermal” plants, boil water to generate steam for electricity generation. Water is also central to hydroelectric power plants that are used in dams and other approaches to store the energy in moving water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.