Explain Flow Diagram of Water Treatment Plant

A water treatment plant transforms raw water from rivers, lakes or wells into clean, safe water for homes, schools and industries. This process reduces disease, supports economic activity and protects the environment. The design and operation of a water treatment plant shape how well a community can meet demand and respond to change. People expect clear water that meets standards. Engineers, operators and managers must deliver that outcome every day.

Understanding how a water treatment plant works helps readers appreciate the steps that remove dirt, microbes and chemicals. It also shows why careful planning and regular upkeep matter.

Raw Water Intake and Screening

Raw water intake and screening set the stage for the entire process. Clean design and reliable intake protect downstream equipment and maintain steady supply. Proper intake prevents large debris and aquatic life from entering the plant. This step also controls flow to match plant capacity and helps operators plan treatment steps. Let us have a look on some important parts of intake and screening.

1: Intake Location and Structure

Engineers choose intake sites to avoid pollution and to access steady water. The location affects sediment levels and biological content. A well placed intake reduces treatment cost and improves water quality.

2: Coarse Screening and Debris Removal

Coarse screens remove sticks, leaves and large objects. These screens save pumps and valves from damage. Operators inspect screens regularly to keep flow steady and to prevent blockages.

3: Fine Screening and Grit Removal

After coarse screening, finer screens and grit chambers remove small particles like sand and silt. This step protects sedimentation basins and filters from abrasion. Grit removal improves filter life and reduces maintenance.

Also Read: Commercial RO Plant Manufacturer

Coagulation and Flocculation

Coagulation and flocculation transform tiny particles into larger ones that settle easily. This stage improves downstream separation and reduces turbidity. Proper chemical selection and mixing ensure that particles gather and form flocs that are strong enough to settle.Let us have a look on some details of coagulation and flocculation.

1: Chemical Dosing and Mix Design

Operators dose coagulants to neutralize particle charge. They design rapid mix zones to spread the chemical quickly. Then they control the slower mixing to grow the flocs. Precise control produces flocs that hold together during settling.

2: Floc Strength and Size

Floc characteristics determine how well particles separate in the next stage. Operators adjust mixing speed and polymer dose to shape floc size and strength. Strong flocs resist break up in filters and in pipes.

3: Monitoring and Jar Testing

Staff run jar tests to select the best coagulant dose for changing water. Regular testing links plant performance to source water conditions. This practice reduces chemical waste and improves clarity.

Sedimentation and Clarification

Sedimentation and clarification remove settled material from water using gravity. This process lowers solids load for filters and simplifies disinfection. Well designed clarifiers make the whole plant more efficient.Let us have a look on some key features of sedimentation and clarification.

1: Settling Basin Design

Engineers size basins for flow and particle load. They place inlet baffles to reduce turbulence. Proper flow paths let flocs fall gently to the bottom where staff collect them as sludge.

2: Sludge Collection and Removal

Sludge gathers at the basin floor. Plant crews remove it with scrapers or pumps. Timely removal keeps basins working and prevents resuspension of particles.

3: Plate Settlers and Tube Settlers

Some plants add plates or tubes to increase surface area for settling. These media shorten basin size and improve clarity. They work well when land or space is limited.

Filtration

Filtration removes remaining particles and reduces microbes. Filters give water a final polish before disinfection. The choice of filter type affects clarity maintenance and operating cost.Let us have a look on some common filter types and their use.

1: Rapid Sand Filters

Rapid sand filters pass water through a layer of sand and gravel. They remove particles by trapping them in the media. Operators backwash the filters to clear trapped solids and restore flow.

2: Slow Sand Filters

Slow sand filters rely on a biological layer to remove organics and microbes. They work well for small communities with low maintenance budgets. Slow sand filters need careful management of head loss and scum growth.

3: Multimedia and Cartridge Filters

Multimedia filters use different layers of material to capture a range of particle sizes. Cartridge filters provide fine polishing for small flows or point of use systems. These options offer flexibility for specific plant goals.

Disinfection

Disinfection kills harmful microbes and prevents water borne disease. Choosing the right disinfectant and dose protects public health while limiting by product formation. Disinfection remains a final barrier before the water goes to consumers.

Let us have a look on common disinfection options and their trade offs.

1: Chlorination and Chlorine Dioxide

Chlorine remains a common disinfectant because it provides lasting protection in the distribution system. Operators monitor residual chlorine levels to keep them within target ranges. Chlorine dioxide works for specific needs and reduces some by products.

2: Ozone and Ultraviolet Light

Ozone provides strong short term disinfection and helps remove tastes and odours. Ultraviolet light inactivates microbes without adding chemicals. Both methods require proper design and maintenance to function reliably.

3: Combined Approaches

Many plants use a combination of methods. They apply UV or ozone for primary inactivation and then add a small chlorine residual for protection in pipes. This approach balances safety with control over by products.

Sludge Handling and Disposal

Sludge handling and disposal deal with the solids that a water treatment plant removes. Proper handling reduces environmental impact and lowers disposal cost. The plant must manage sludge volume and treat it to meet regulations.Let us have a look on common sludge practices and technologies.

1: Thickening and Dewatering

Plants thicken sludge to concentrate solids and reduce volume. They then dewater using presses or centrifuges. These steps cut transport and disposal cost and improve storage.

2: Stabilization and Conditioning

Operators may condition sludge with chemicals or let microbes stabilize it. Stabilized sludge poses less odour and less risk. Conditioning also helps mechanical dewatering.

3: Disposal and Beneficial Use

After treatment plants dispose of sludge at approved sites or use it as soil amendment when regulations allow. Safe reuse can close resource loops and reduce waste.

Instrumentation and Control

Instrumentation and control let operators run the plant with precision. They measure quality flow and chemical dose. Modern control makes the plant more efficient and more responsive to change.Let us have a look on key control functions.

1: Sensors and Online Analyzers

Sensors measure pH, turbidity, chlorine and flow in real time. Operators use these readings to adjust chemical feed and process speed. Reliable sensors reduce the need for manual checks.

2: SCADA and Automation

Supervisory systems collect data and let operators control the plant remotely. Automation handles routine tasks and logs events. Staff still make decisions but systems reduce human error for repeated actions.

3: Alarms and Fail Safe Design

Alarms alert staff to out of range conditions. Fail safe designs ensure pumps and valves move to safe positions during power loss. These features protect water quality and equipment.

Operation and Maintenance

Operation and maintenance keep the plant performing day after day. Skilled operators and clear procedures extend equipment life. Regular care also lowers unplanned shutdowns and helps meet quality targets.Let us have a look on the routine tasks and training needs.

1: Daily Rounds and Checks

Operators monitor gauges, sample water and inspect equipment each day. These checks help catch problems early. A strong culture of observation prevents small issues from becoming major failures.

2: Preventive Maintenance

Scheduled maintenance replaces worn parts and cleans critical components. Preventive work reduces emergency repairs and makes budgets predictable. Records of maintenance help managers plan upgrades.

3: Staff Training and Knowledge Transfer

Plants invest in training to keep skills current. Cross-training helps the team cover for absences. Clear manuals and hands-on practice build confidence and support safe operation.

Environmental and Regulatory Considerations

A plant must meet laws and standards that protect public health and the environment. Compliance shapes design and daily activity. Plants that track rules and engage regulators avoid fines and protect community trust.Let us have a look on the main compliance areas and how plants respond.

1: Water Quality Standards

Regulators set maximum levels for contaminants and minimum disinfectant requirements. Plants run tests and report results to remain in compliance. Consistent quality builds public confidence.

2: Effluent and Sludge Rules

Disposal of used backwash water and treated sludge must meet discharge limits. Plants design treatment for these waste streams to prevent harm to rivers and soils.

3: Environmental Monitoring and Reporting

Plants monitor the receiving environment and send reports to authorities. Transparent reporting supports community dialogue and shows commitment to safe operation.

Energy and Cost Efficiency

Energy and cost efficiency affect the plant budget and carbon footprint. Smart choices lower bills and reduce environmental impact. Efficiency also extends equipment life and improves resilience.Let us have a look on measures that improve efficiency.

1: Pump and Motor Selection

Energy efficient pumps and motors use less electricity and reduce heat. Engineers size equipment to match demand. Variable speed drives cut energy use during low flow periods.

2: Process Optimization

Operators tweak steps to reduce chemical use and lower head loss. Better control means less waste and less cost. Regular audits find savings that add up over time.

3: Renewable Energy and Recovery

Some plants use solar panels or recover heat from wastewater to cut grid use. These measures lower operating cost while supporting sustainability goals.

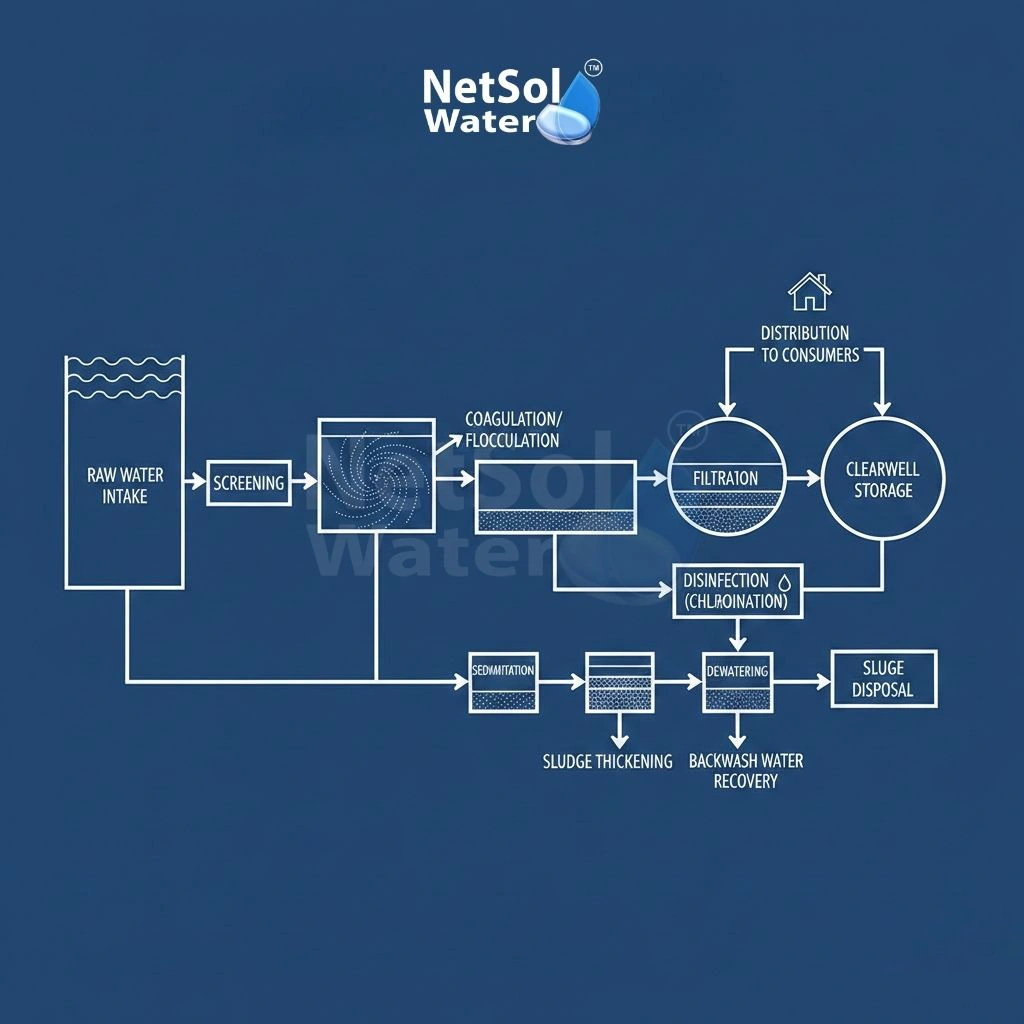

Flow diagram of water treatment plant

Conclusion

A well planned water treatment plant puts health, safety and service first. The sequence from intake to disinfection forms a chain where each link must work well. Good design careful operation and steady maintenance make the system reliable. Meeting regulatory rules and seeking energy savings improve long term performance.

If you want more details on how a water treatment plant can meet your local needs, we can help. Reach out to request an assessment or a consultation. We will review site conditions explain options and prepare a clear plan that fits your goals. Contact us to learn more about practical steps for delivering safe clean water.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com