How does a commercial RO Plant work?

The RO plant removes contaminants by forcing unfiltered water through a semipermeable membrane under pressure. RO plants produces drinking water by moving water from a highly concentrated side (with more impurities) to a less concentrated side (with fewer contaminants).

Commercial RO plants use a semipermeable membrane. Thousands of microscopic pores make up this membrane, which block contaminants while allowing water molecules to pass through. In this way, it provides safe drinking water.

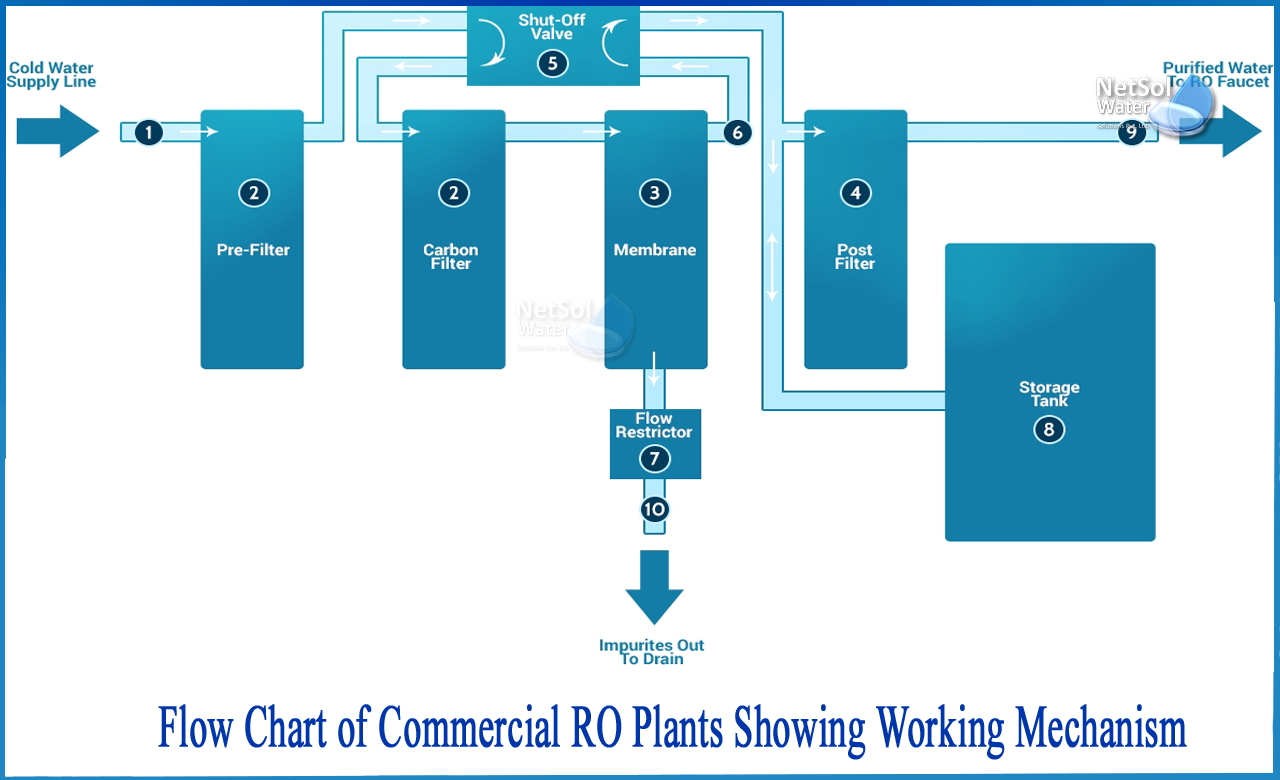

A: Flow Chart for working mechanism of Commercial RO plants

In commercial reverse osmosis, three to five stages take place.

A sediment filter, a carbon filter, and a semipermeable membrane are all part of a three-stage reverse osmosis system.The basic steps of a commercial reverse osmosis system are as follows:

1: Pre-filtration:There are two types of pre-filters in reverse osmosis systems that filter out bigger particles like silt and chlorine. The water passes through a sediment pre-filter, which filters out particles such as dust, silt, and rust. The water then passes through an activated carbon pre-filter, which binds to and eliminates contaminants such as chlorine and volatile organic compounds (VOCs).

2: Reverse osmosis:The major event of reverse osmosis follows pre-filtration. The water is then passed across a semipermeable membrane, which traps tiny, more difficult-to-remove dissolved solid particles. Reverse osmosis may often remove the vast majority of dissolved solids from water at this stage.

3: Drainage:The following phase is drainage, which sends the eliminated contaminants down the drain after the water has passed through the semipermeable membrane. Contaminants that build up on the membrane can reduce its effectiveness, therefore this step is critical. The RO system's efficiency is maintained by draining the collected contaminants.

4: Storage:The last step is to store the treated water until it is needed. A pressure tank large enough to hold the treated water without requiring waste is frequently used as the storage container. The cleaned water may also pass through a charcoal filter to eliminate any remaining contaminants.

B: Flow chart for Process flow of Commercial ROplants

Three processes are involved in the flow process of commercial RO: pre-filtration (micro-filtration and activated carbon adsorption), purification, and post-filtration (re-mineralization).

a) Pre-filtration: An adsorption filter and a micron filter are used to remove hazardous particles; a string wrapped filter element with a pore size of 5 micron is acceptable. The chlorine is adsorbed by an activated carbon (AC) filter, which eliminates the odour and taste.

b) Purification: To reduce the contaminants, low RO filtering is recommended.

c) Post filtration: After purification, the permeate is moderately acidic and chemically tasteless. The permeate is passed through an 8 mm mineral cartridge to achieve a healthy alkaline pH level of above 7.

C: Flow chart for different stages of Commercial RO systems

I.Three stag?e reverse osmosis system:

Stage 1 Carbon prefilter: An activated carbon pre-filter eliminates chlorine and other elements that make water taste and smell bad. To safeguard the RO membrane, the carbon pre-filter eliminates chlorine.

Stage 2 The RO membrane: This stage removes dissolved solids such as radium, lead, arsenic, and other contaminants.

Stage 3 Activated carbon filter: This stage has a second activated carbon filter that polishes the water to ensure it is perfectly clean.

II. Five stage Reverse Osmosis system:

Stage 1 Sediment prefilter: Dirt, sand, rust, and other microscopic particles 15 times smaller than a grain of sand, are filtered out by a sediment prefilter.

Stage 2 Carbon prefilter: An activated carbon prefilter eliminates chlorine and other elements that make water taste and smell bad.

Stage 3 Second carbon prefilter: A second activated carbon prefilter decreases components that make water taste and smell bad, such as chlorine flavour and odour.

Stage 4 Reverse osmosis membrane: This removes dissolved solids such as radium, lead, arsenic, and other contaminants.

Stage 5 Polishing filter: The polishing filter is a second activated carbon filter that polishes the water and ensures that it is crystal clean.

Are you looking for the best Commercial RO Plant Manufacturers in India?

Netsol Water collaborates with a wide range of international organizations to tackle complicated Reverse Osmosis problems by strategically integrating modern treatment technology with practical solutions.

We are the market leaders in Commercial RO Plants, Industrial RO Plants, Sewage Treatment Plants, and Effluent Treatment Plants, thanks to our cutting-edge technology.We customize water treatment systems to meet customers' specific needs at a fair price. We offer completely automated and semi-automated systems.

RO Plants that we provide are made of chrome steel or stainless steel, which assures that the water system will last longer. Our Commercial RO plants can be placed in almost every institution including schools, universities, or malls, offices, hospitals, dental clinics, housing societies, apartment complexes, hostels, restaurants, hotels, caravan parks, camping sites and much more.